Energy-saving technology and equipment for vibration stabilization of residual stresses

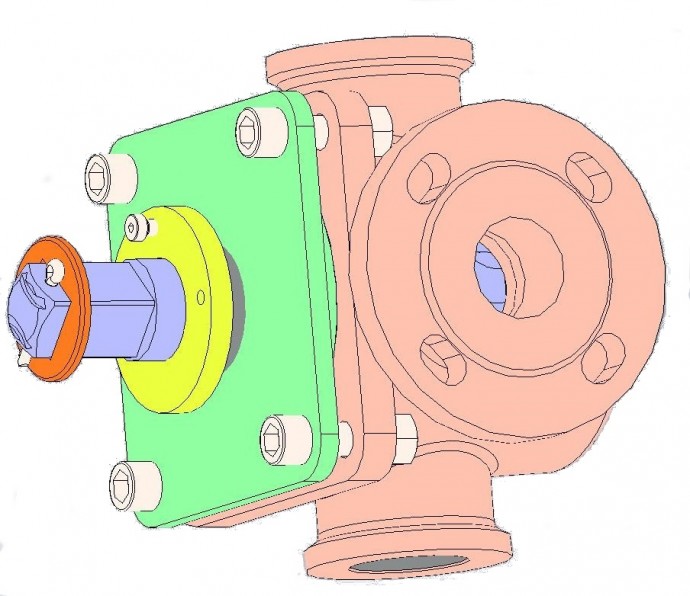

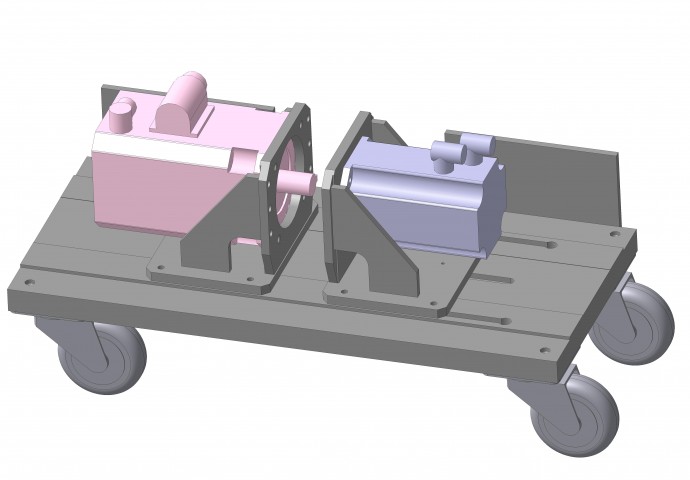

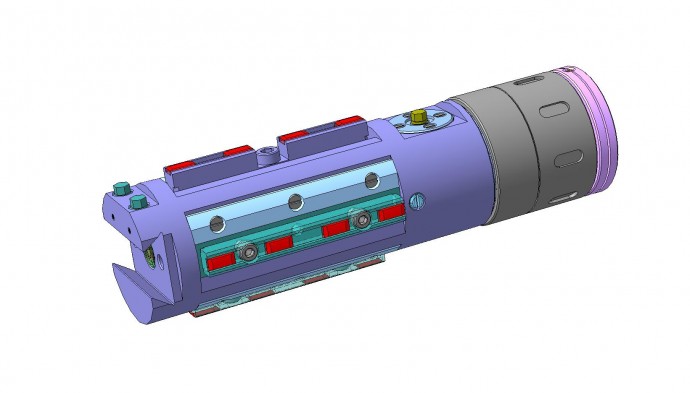

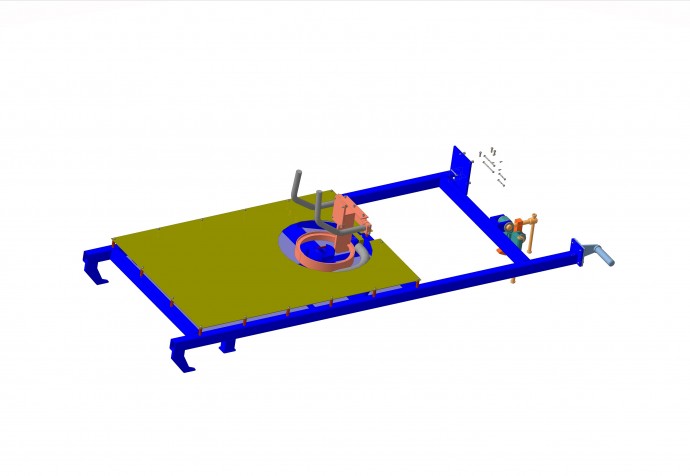

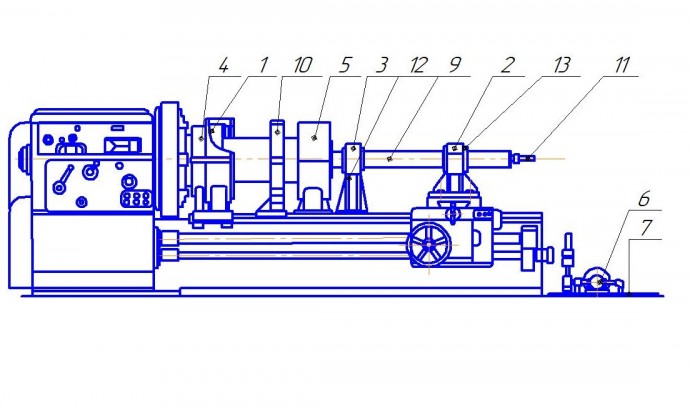

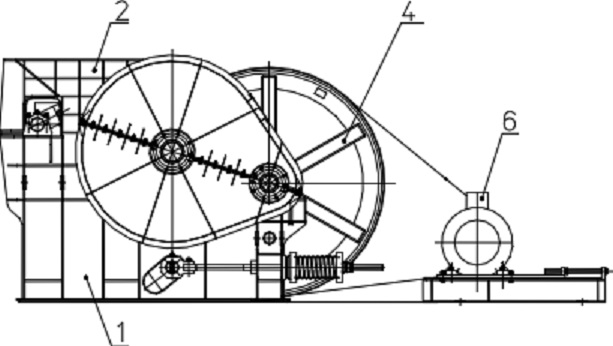

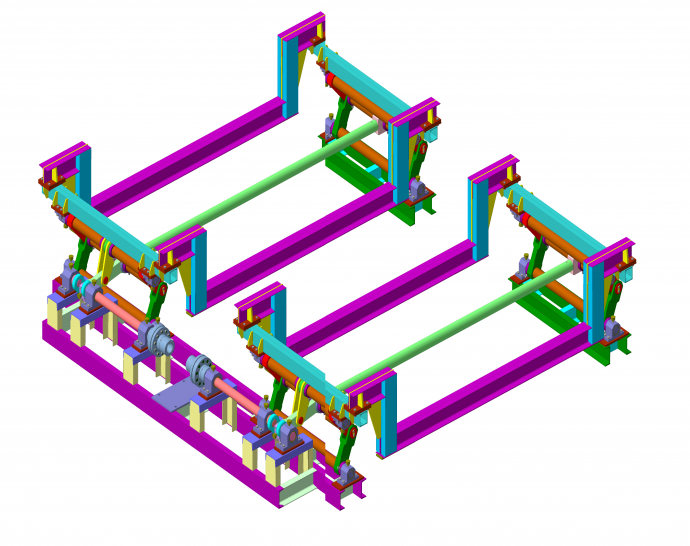

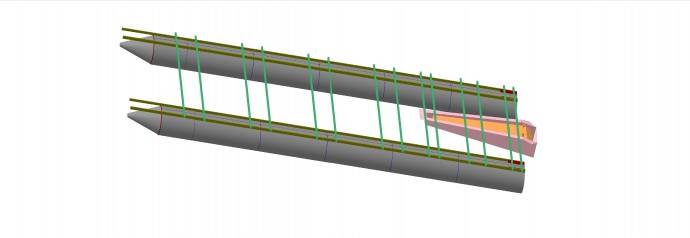

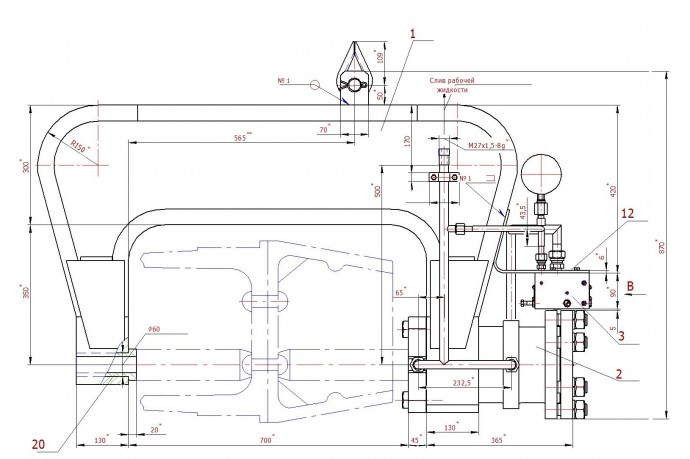

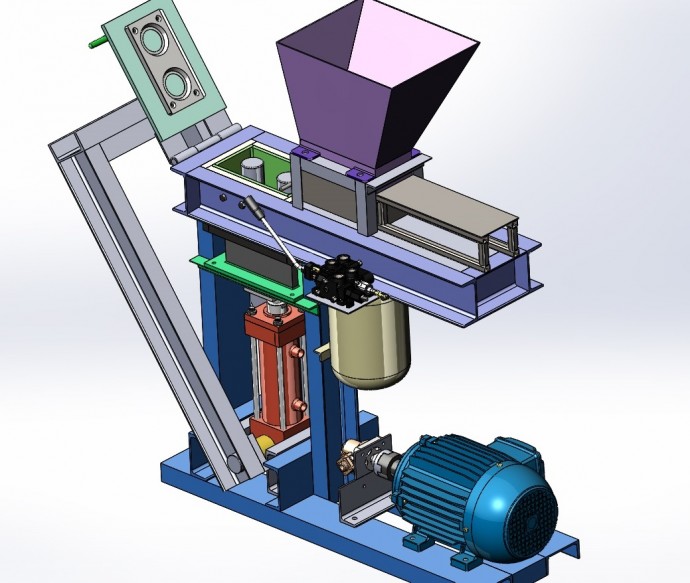

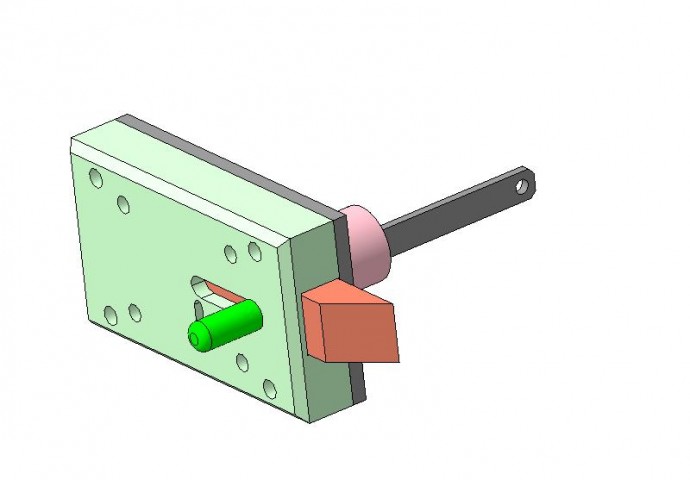

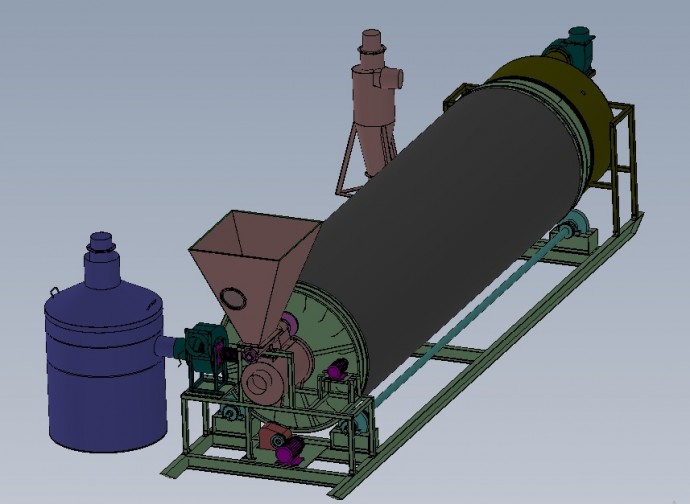

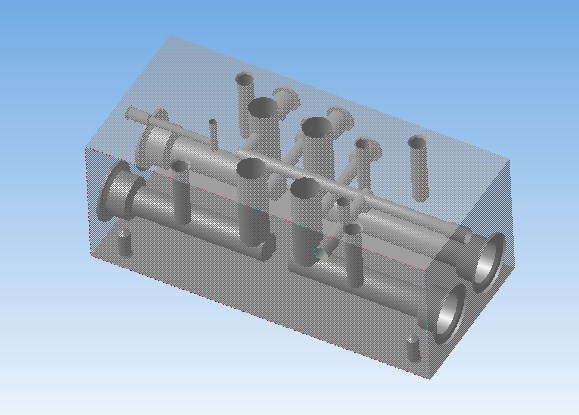

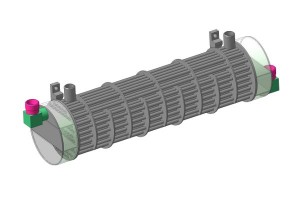

Energy-saving technology and computerized equipment for vibration deformation (accelerated) aging of parts are designed to stabilize residual stresses in welded, cast and other dynamically non-rigid metal products with a mass of up to 50 tons, such as cores, frames, shafts, cogwheels, beams of presses, carriages of wagons, locomotives and the like. instead of stabilization annealing and other types of artificial and natural aging.

It is possible to use this technology for cold dressing of non-rigid products due to the use of potential energy of residual stresses.

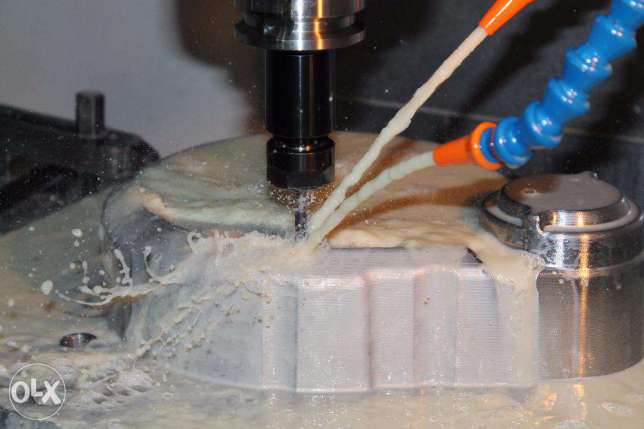

Vibration stabilization can be performed depending on the type of billet, the nature of production and the technical requirements for the final product both immediately after the preparation of the billet and in the interval between the stages of machining.

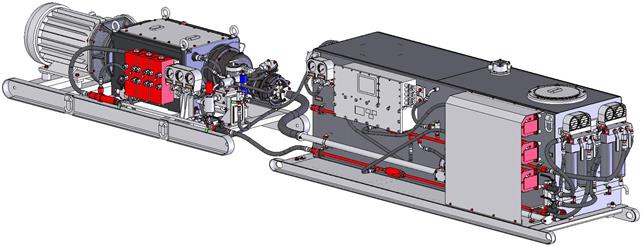

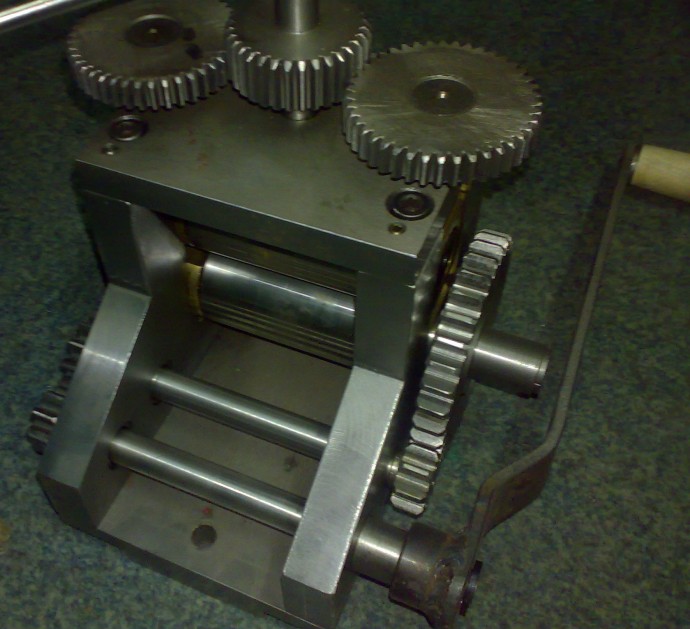

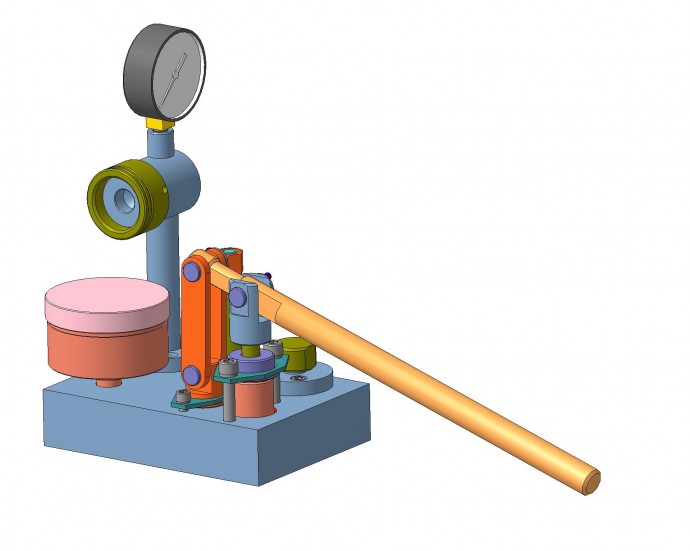

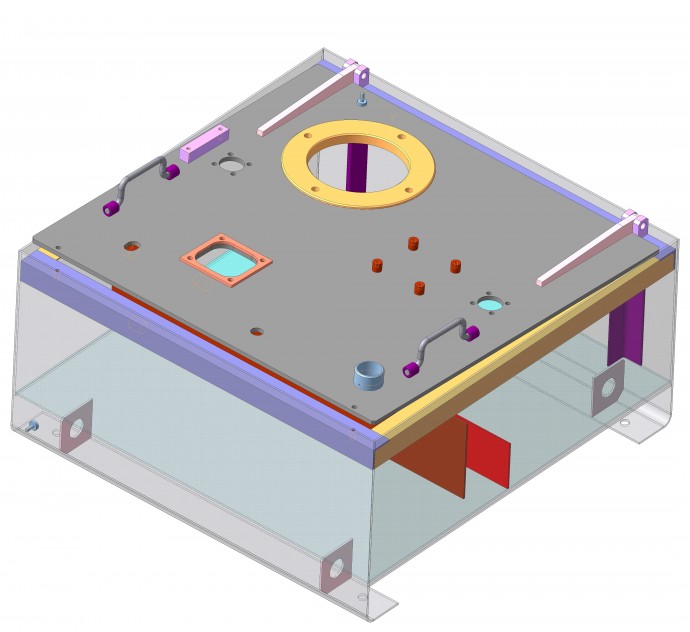

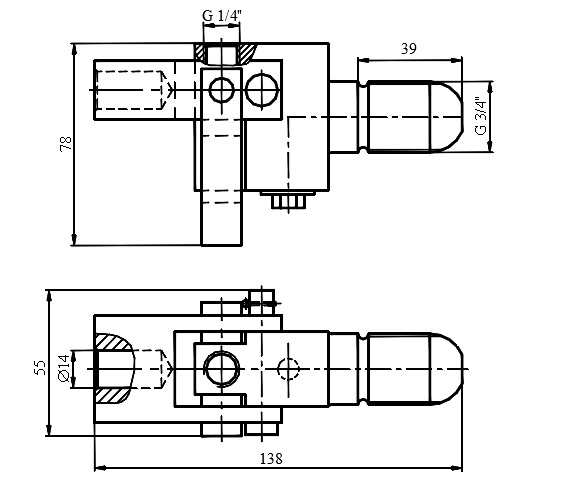

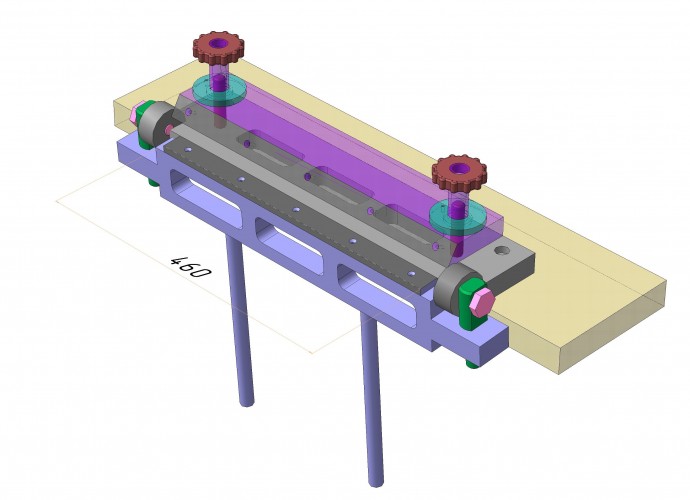

Technical characteristics of the vibrating installation mod. VSON 2100/2500

Characteristic | Value |

|---|---|

| Range of disturbance force regulation, N | (0,15…2,1)х104 |

| Range of speed of unbalanced mass, min-1 | 600…6000 |

| Power of the exciter electric motor, kW, in the mode: | |

| nominal | 0,78 |

| forced | 1,3 |

| Consumed current of exciter, A | 40 |

| Supply voltage, V | |

| exciter | 27 |

| installations | 380 |

| frequency Hz | 50 |

| Power consumption, kW, not more than | 1,5 |

| Life time | not less than 5 years. |

| In terms of resistance to climatic influences during operation, the installation corresponds to the performance of UHL category 3.1 according to GOST 15150-69. | |

| According to the method of protecting a person from electric shock, the installation corresponds to class I in accordance with GOST 12.2.007.0-75. | |

| Overall dimensions, mm | |

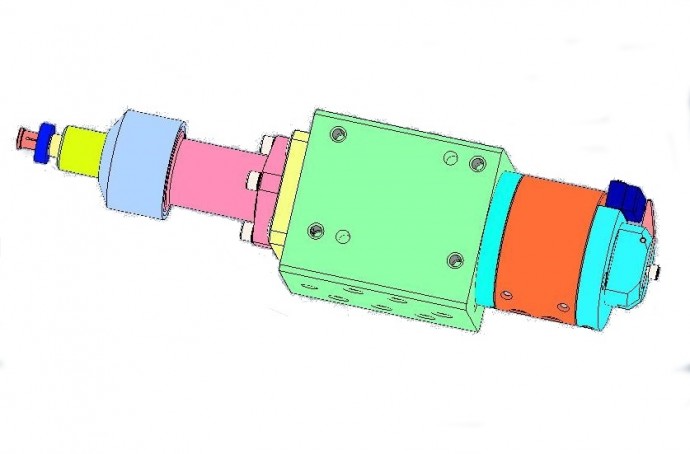

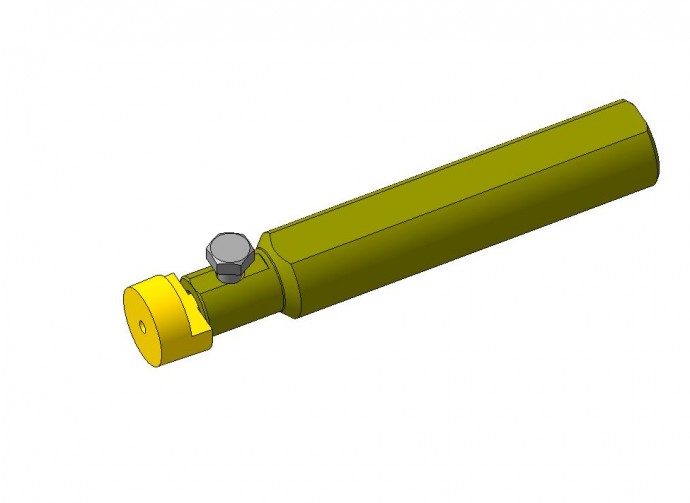

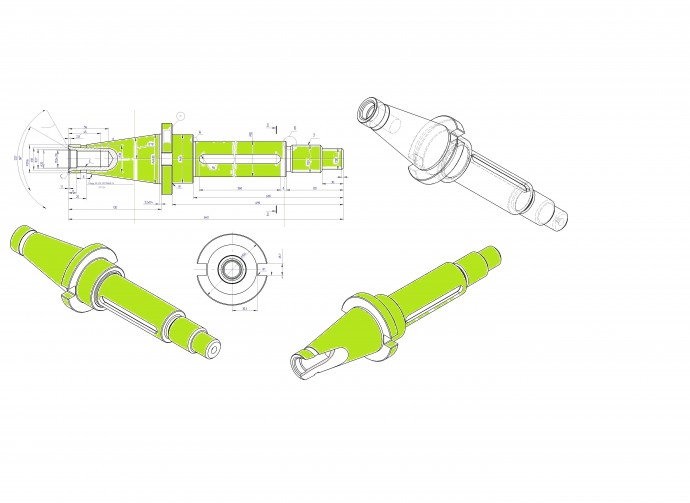

| exciter (length, height, width) | 465х265х360 |

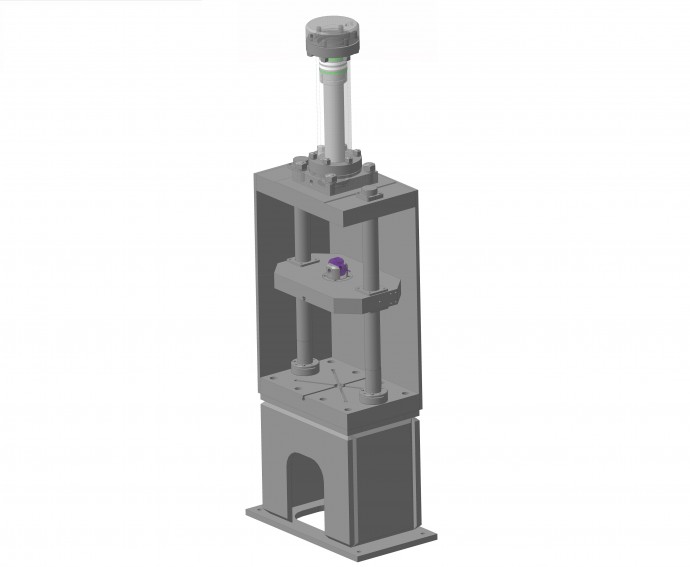

| cabinet (length, height, width) | 1130х1179х669 |

| Weight, kg, no more than | |

| cabinet | 180 |

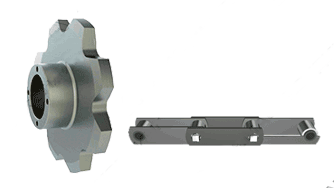

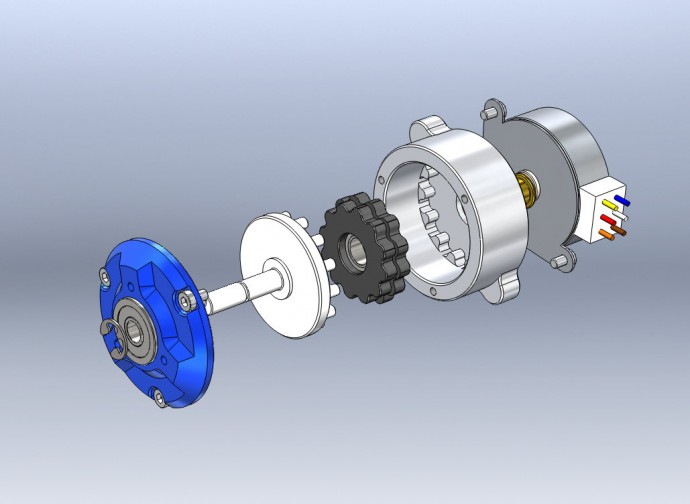

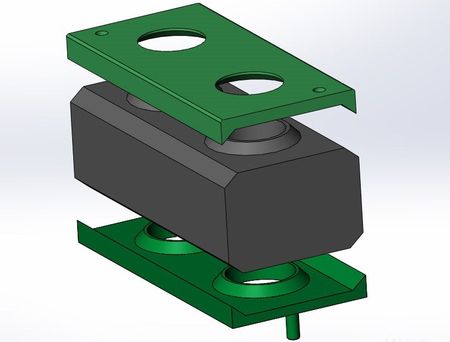

| vibro-exciter (with built-in electric motor) | 55 |

| three vibro sensors in the assembly and an amplifier unit for taking characteristics in 3 orthogonal planes and the resultant | 1,9 |

connecting cables | 4,2 |

Advantages of the developed technology of accelerated vibrodeformation aging:

1. Absence of deformations (deplanations) arising during the removal of "OH" during low-temperature annealing (artificial aging).

2. Mechanical properties (σ; σв, δ) do not change under tension, and due to intercrystalline friction, an increase in rigidity takes place in the corresponding modes in the course of vibration processing (the part is elongated during heat treatment).

3. Low production costs (less than 10% of annealing costs), costs for inter-shop transportations, expenses for lifting and transport operations are reduced.

4. The vibration processing is a mobile process, it can be performed for details of any size (there are no limitations related to the dimensions of the furnace).

5. Decarburization does not take place, scaling is formed. reduction of the percentage of carbon in the workpiece (the metal "softens"), and the burning out of oxygen, especially in the welds, causes structural heterogeneity in them and contributes to reducing the resistance to cracking.

6. There are no problems related to ecology and sanitary norms.

7.Technology on the recommended regimens does not cause a decrease in the cyclic endurance of products. The use of traditional thermal methods for "removing" residual stresses in structural steel is not only an expensive method, but also not applicable due to the reduction of mechanical properties to 25% (steel 3) and more than 48% for 09G2S steels.

8.Technology allows to perform quality diagnostics (presence or absence of defects) of metal structures by parametric resonance and amplitude drift under phase shift.

The cost of buying a vibration unit and the introduction of vibration aging technology pay off after processing two 25-30-ton non-rigid welded metal structures or cast, welded-cast products.

en

en ru

ru uk

uk