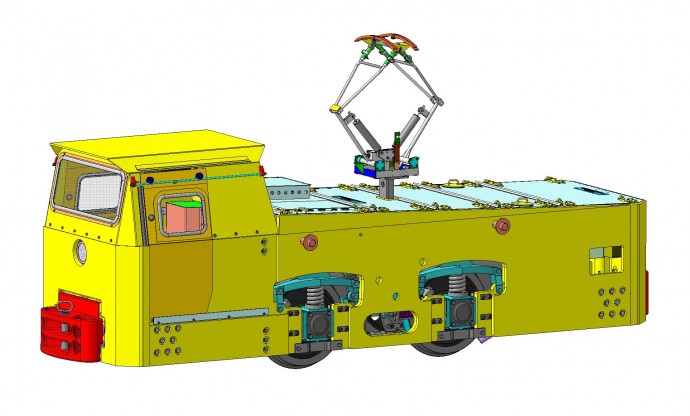

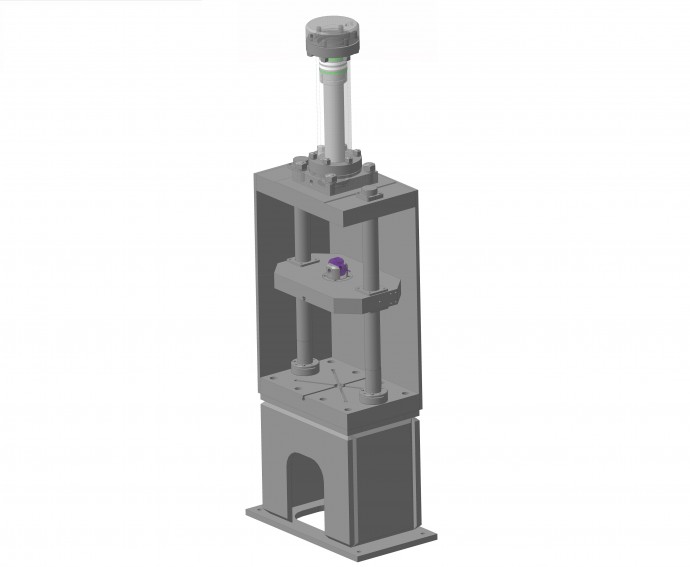

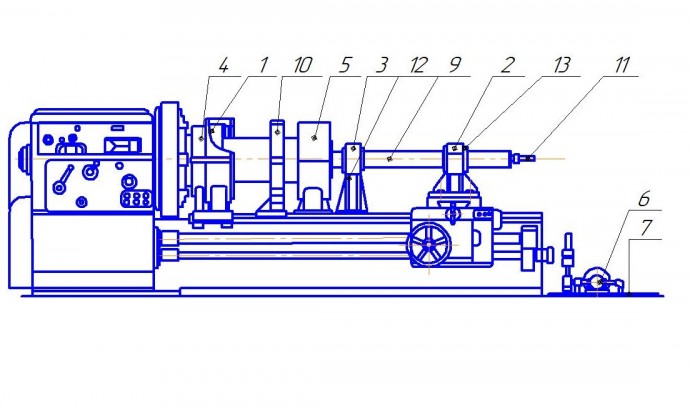

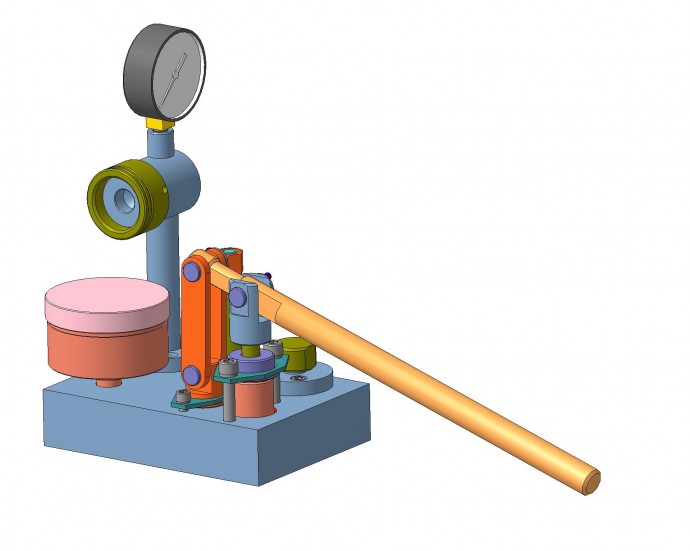

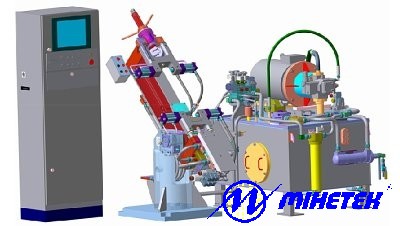

Stand for testing hydraulic vibration dampers (dampers) of cars and locomotives

Modifications of stands developed by NPO MINETEK-TECHNOLOGIES fully cover all types of dampers that currently exist and that may be developed in the future. The stands are certified by UkrSEPRO (registration number No. UA 1.080.0006407-10).

The main consumers of the stands are carriage and locomotive depots, research centers, manufacturers of hydraulic vibration dampers, as well as repair enterprises of military and transport engineering.

Our company was the first in the world to apply an artificial intelligence algorithm to recognize "patterns" of malfunction of hydraulic shock absorbers of wagons and locomotives in its serially produced stands for testing hydraulic shock absorbers.

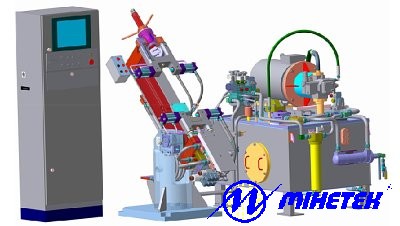

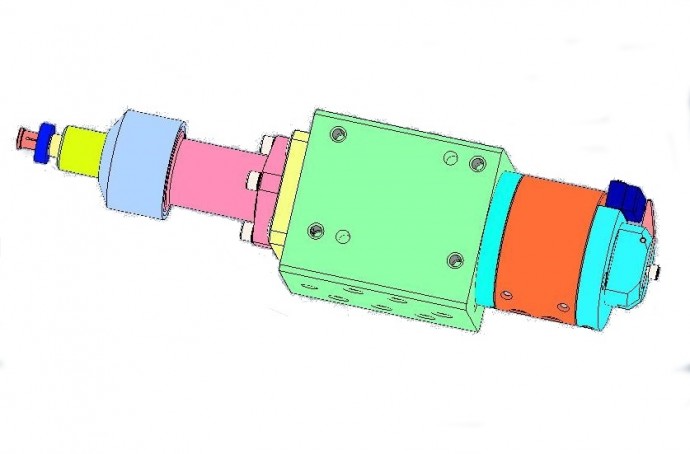

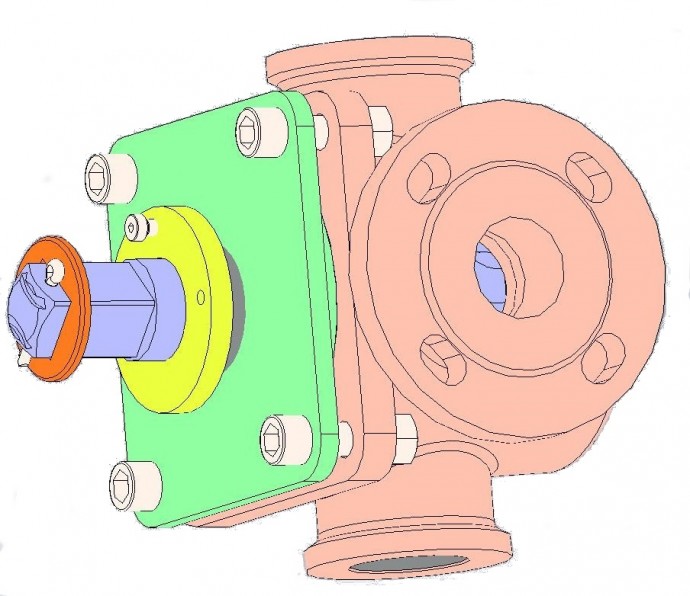

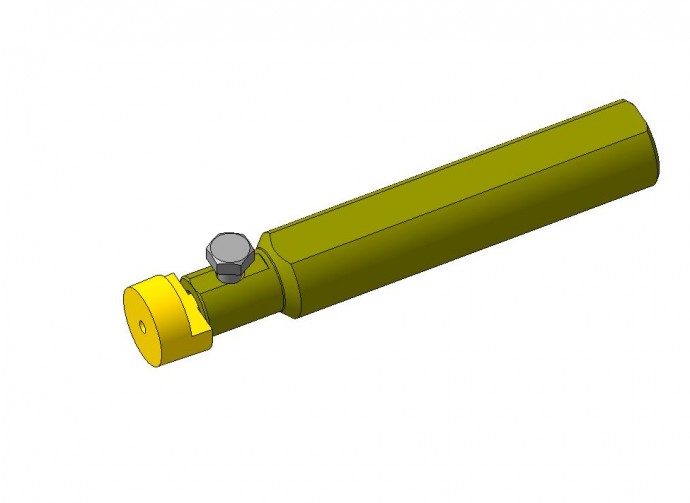

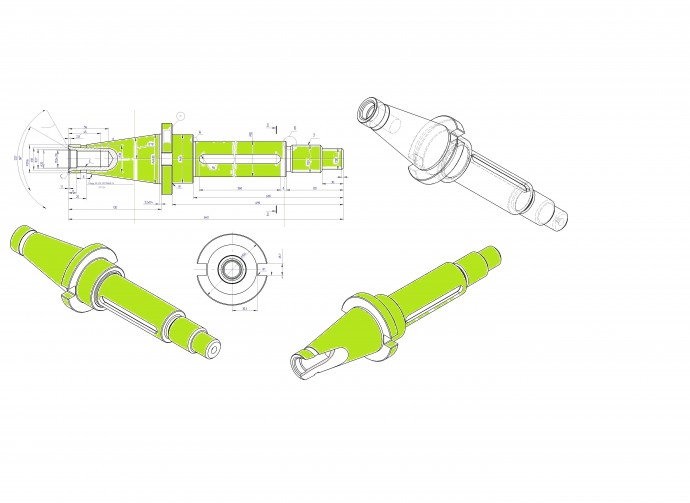

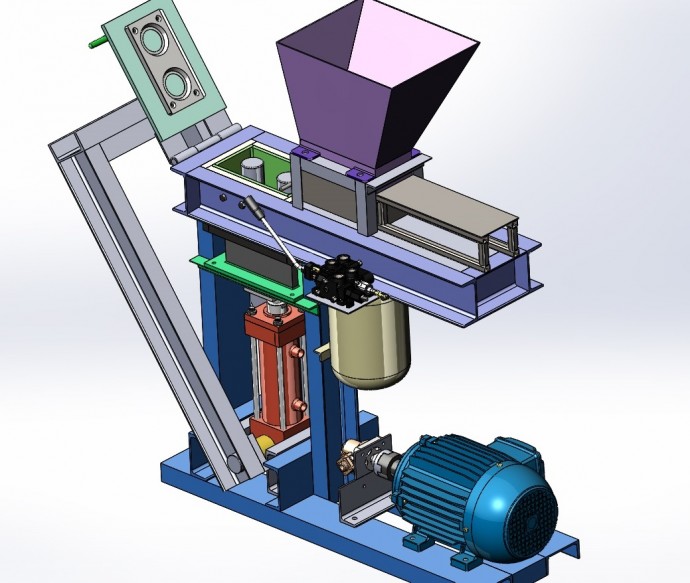

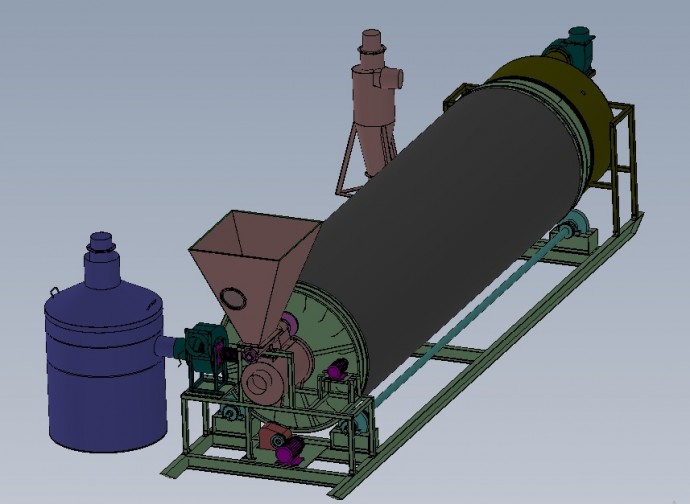

At the request of the customer, the stands can be supplied with various configurations and functionality, realizing the speed of movement of the damper piston according to the sinusoidal and non-sinusoidal law from 0.02 m/s to 0.6 m/s, the highest tensile compression force of up to 25 kN and the stroke of the power piston hydraulic cylinder from 10 to 100 mm.

A distinctive feature of the stands is:

-high reliability;

- the ability to implement, using software, any technical characteristics of dampers and the law of movement of the damper piston;

- ease of maintenance;

- the presence of a highly intelligent system for recognizing damper malfunctions and recommendations for their repair, based on modern mathematical algorithms developed by scientists of NPO "MINETEK-TECHNOLOGIES";

this technology was developed and applied for the first time in the world by scientists of our enterprise back in 2001, in confirmation of which a Ukrainian Patent for an invention was received

- speed of changeover of the stand to the required standard sizes of absorbers.

- since 1998, infrared sensors have been installed at our stands to monitor the temperature of the vibration damper during testing, which gives competitive advantages in obtaining and processing information about the vibration damper being tested

Our stands have been supplied and operated in the CIS countries and the European Union

More than 20 years of scientific school allows us to create both new test benches and new hydraulic vibration dampers.

Technical specifications

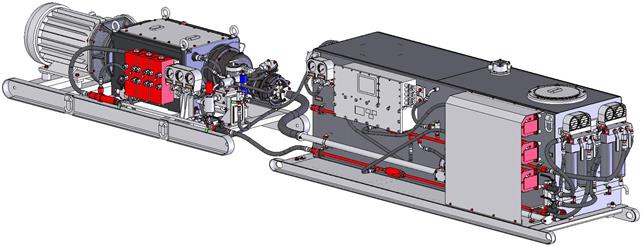

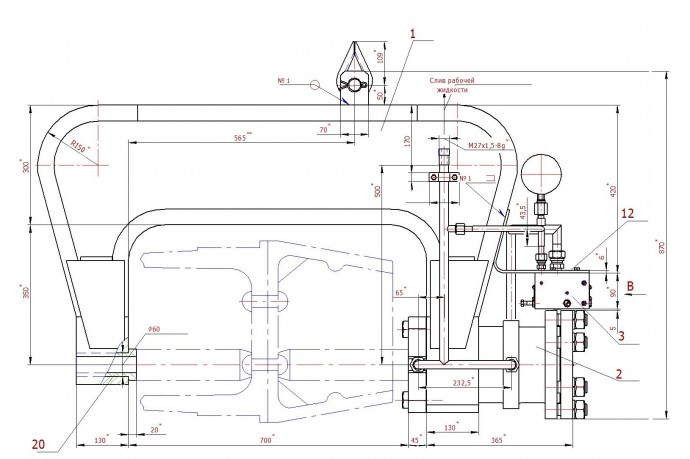

As an example, a modification of the computerized stand SVD 16-0.3PT3R is given, which has the following technical characteristics:

| Характеристика | Значение |

|---|---|

| Наибольшая сила растяжения-сжатия гасителя, кН | 16 |

| Диапазон регулирования мгновенных скоростей перемещения поршня гасителя относительно его цилиндра, м/сек | от 0,02 до 0,3±5% |

| Номинальный ход поршня при испытании гасителя, мм | 100±5 |

| Давление в гидросистеме, МПа, не более | 8,5 |

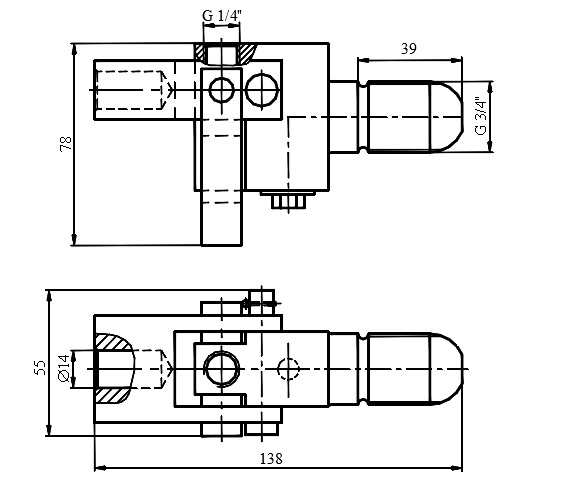

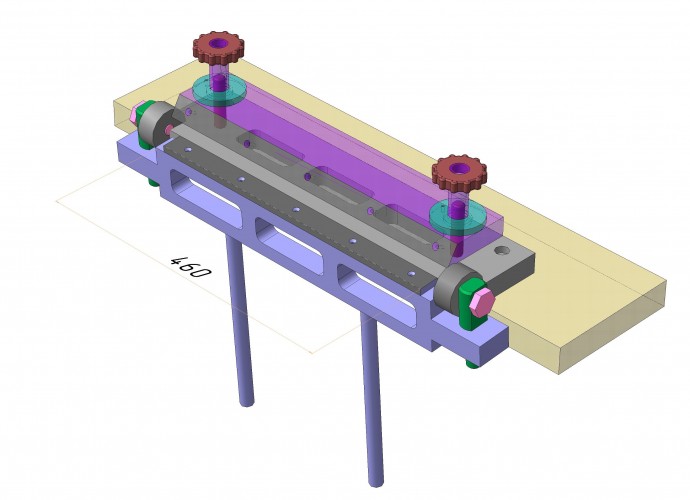

| Расстояние между осями зажимов гасителей, мм | от 370 до 550 |

| Характеристика рабочей жидкости: | |

| кинематическая вязкость при температуре жидкости 50 °С, м2/с | от 30 до 40 |

| номинальная тонкость фильтрации, мкм | 10 |

| класс чистоты по ГОСТ 17216-71, не грубее | 10 |

| Потребляемая мощность, кВт, не более | 22 |

| Напряжение питания, В | 380±10% |

| Частота тока, Гц | 50±1 |

| Габаритные размеры (ВхLхН), мм, не более: | |

| при горизонтальном положении испытуемого гасителя | 2005х2850х1850 |

| при вертикальном положении испытуемого гасителя | 1895х2850х1965 |

| Масса стенда (без масла), кг, не более | 1700 |

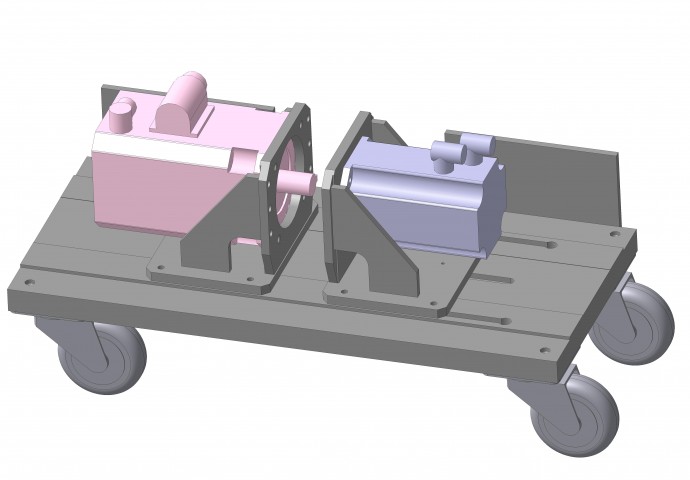

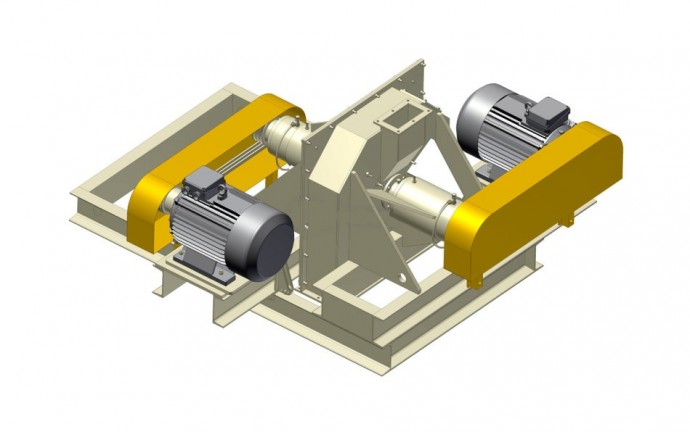

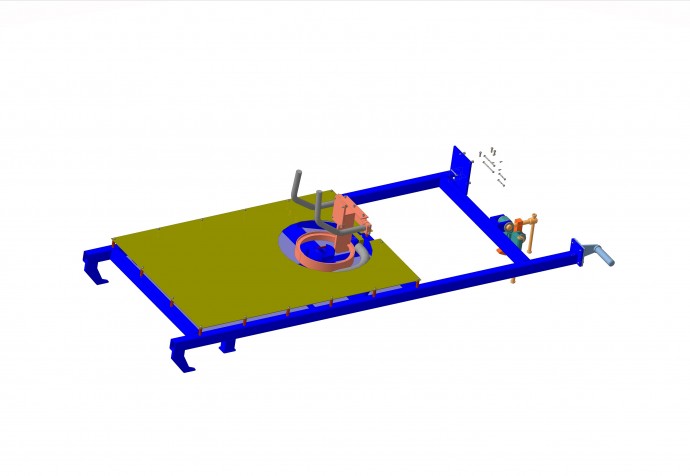

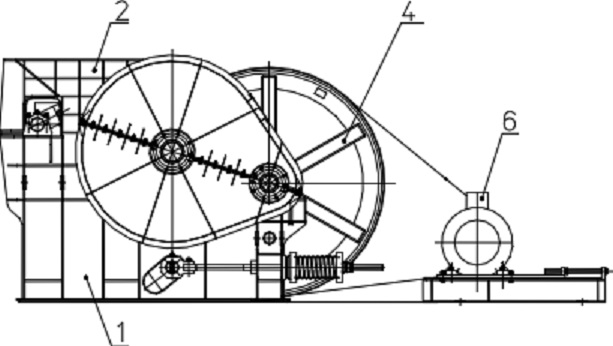

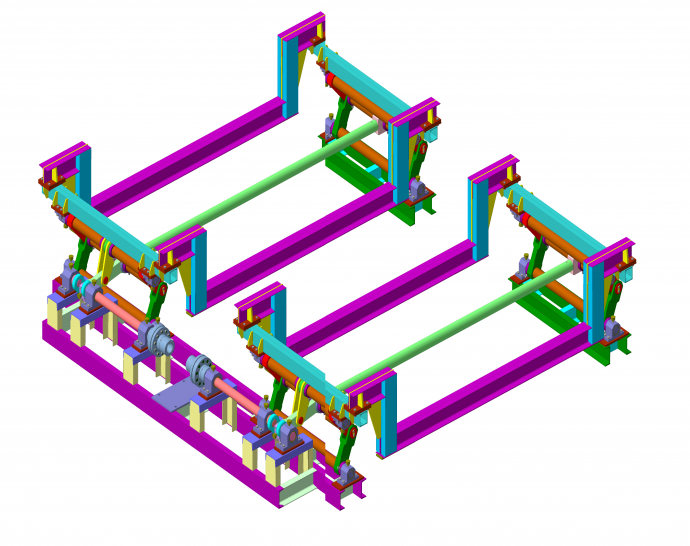

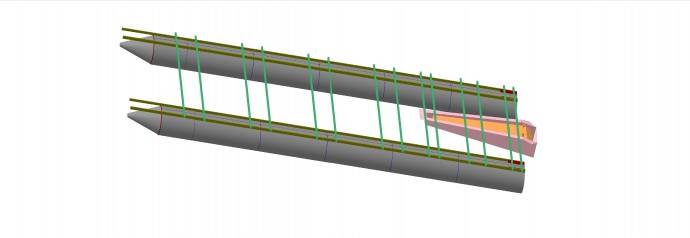

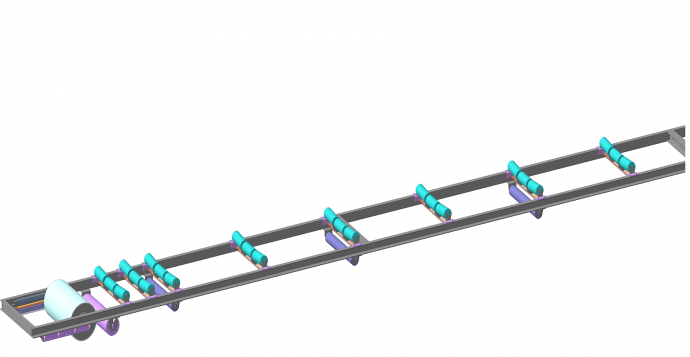

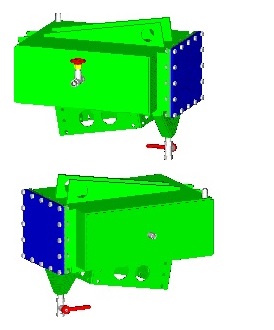

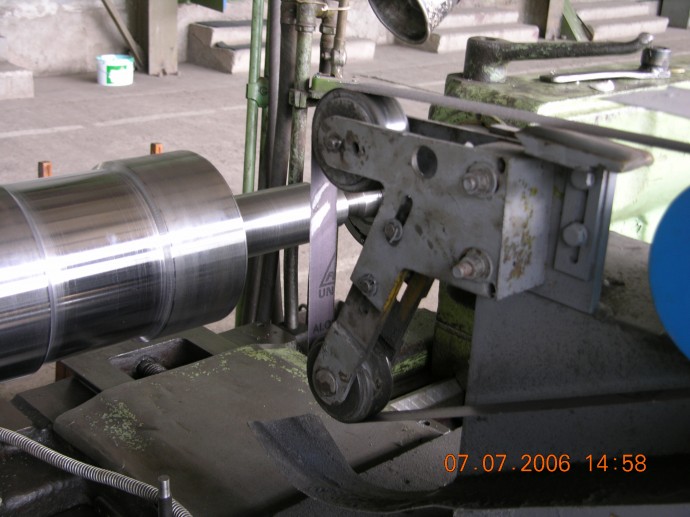

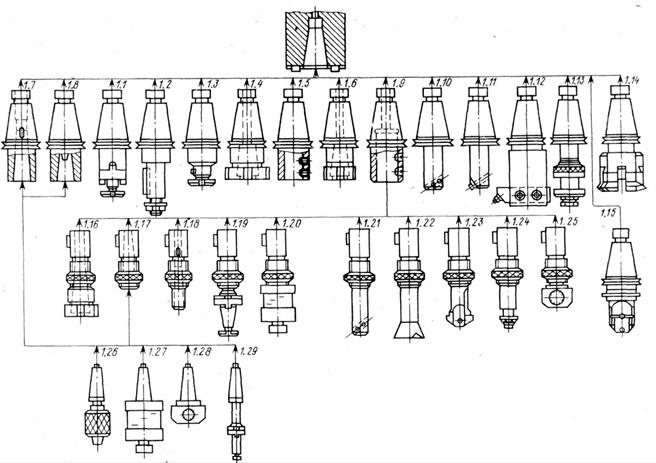

The movable frame of the mechanical part has the ability to rotate from horizontal to vertical position and can be fixed relative to the horizon at angles of 0º, 15º, 30º, 45º, 60º, 75º and 90º

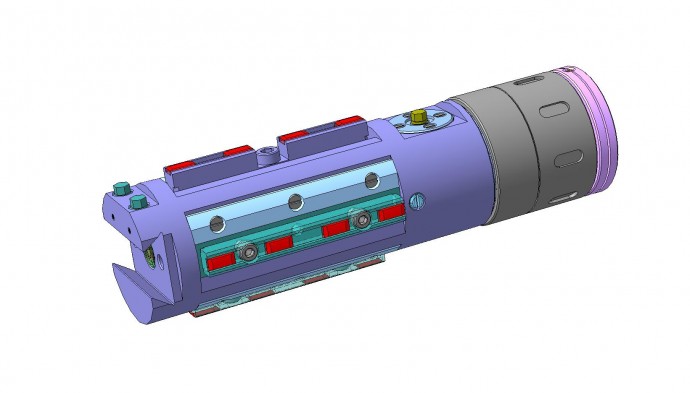

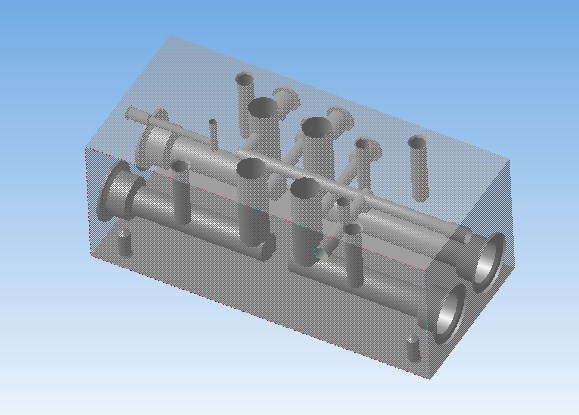

The developed bench equipment makes it possible to conduct a full comprehensive test of hydraulic vibration dampers and determine their characteristics at any speed and displacement scanning section in the form of a diagram of the dependence of force on speed (power characteristic), force on path (pie chart) and the energy intensity of the damper. During testing, the method of comparative analysis of the specified quality indicators of new dampers with the indicators of dampers that have completed their scheduled service life is used.

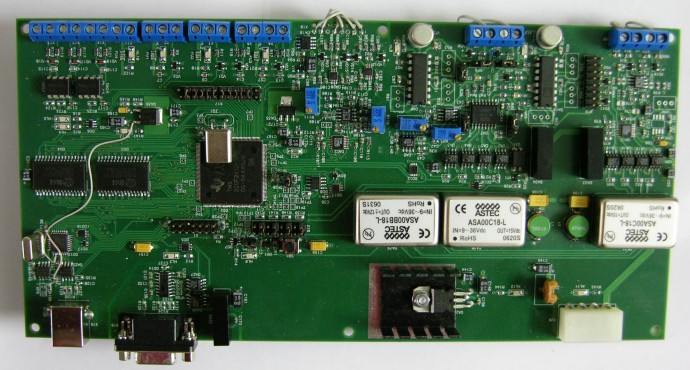

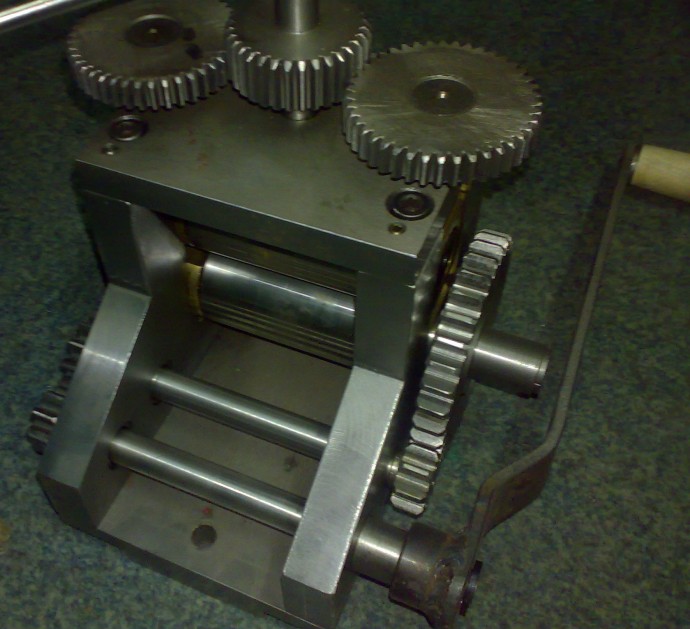

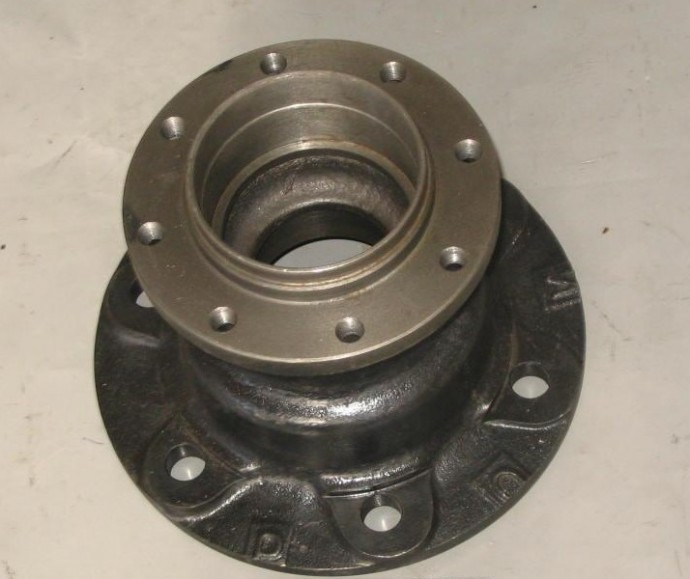

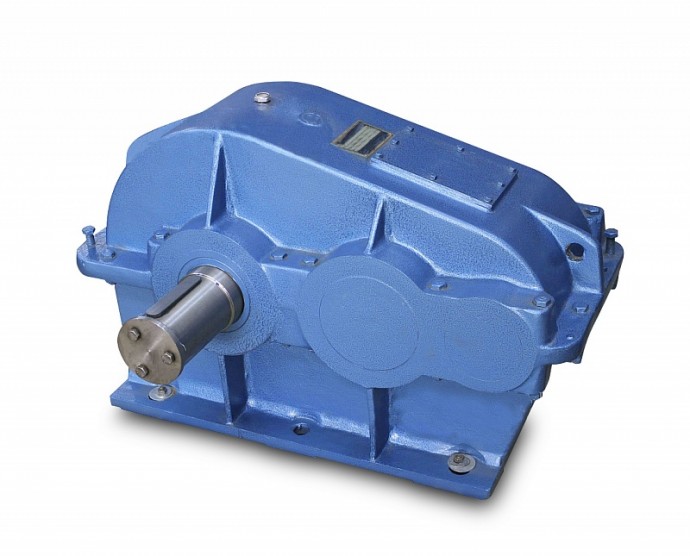

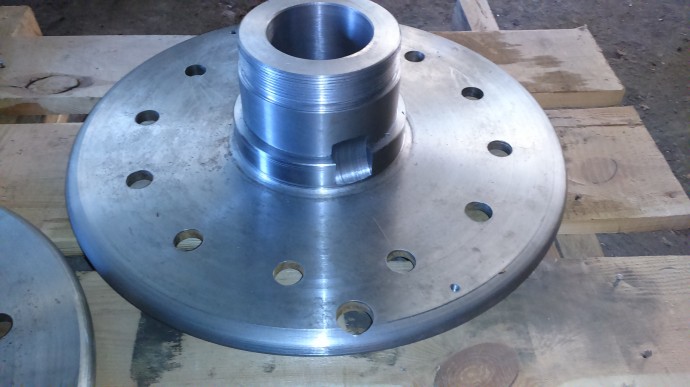

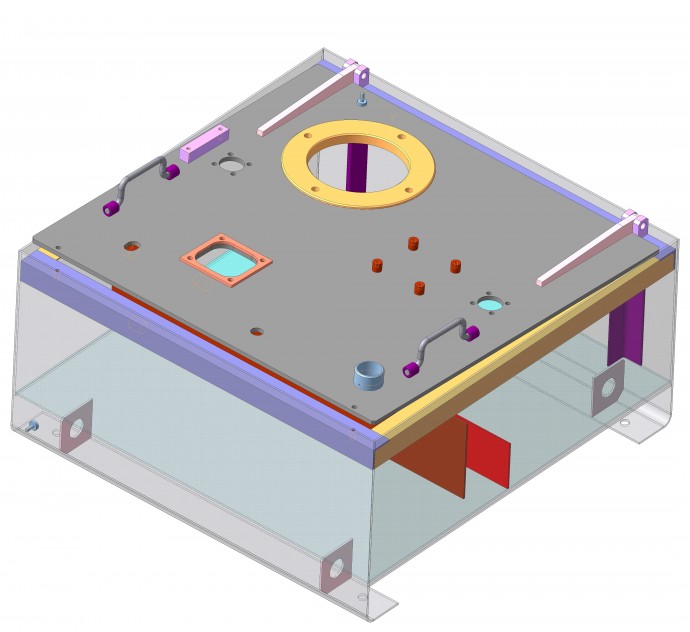

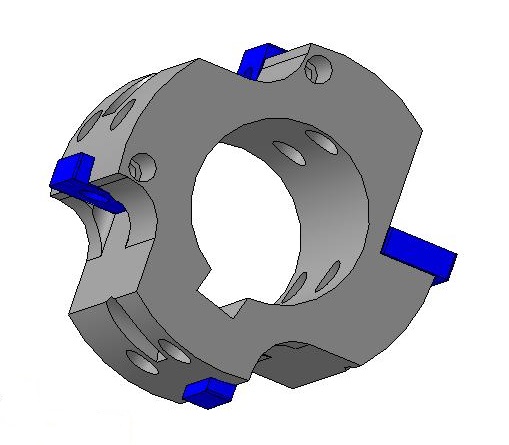

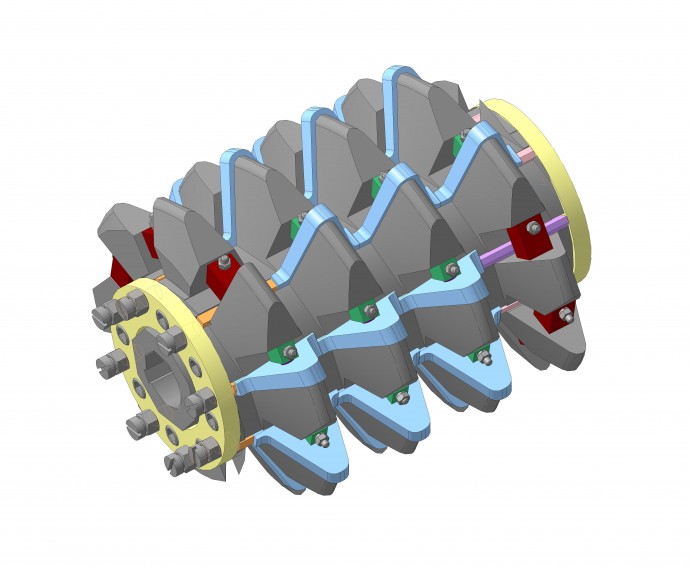

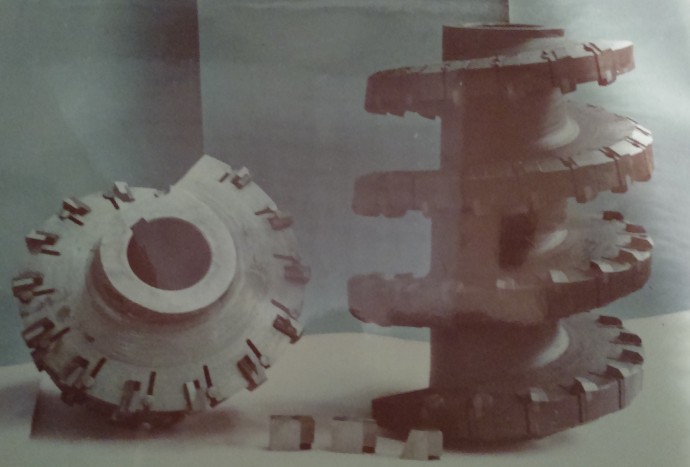

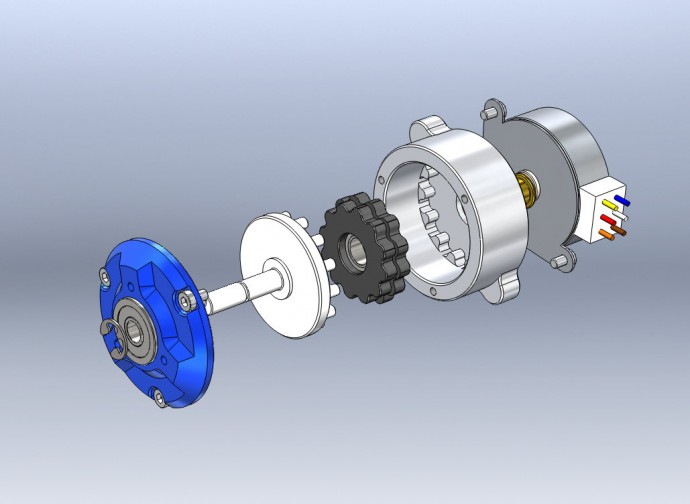

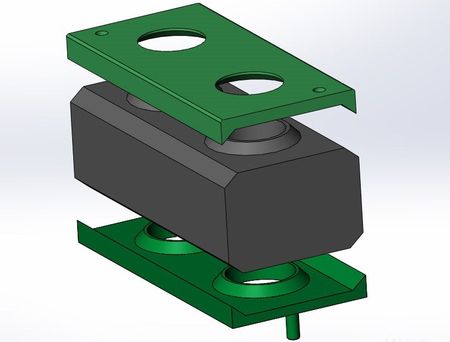

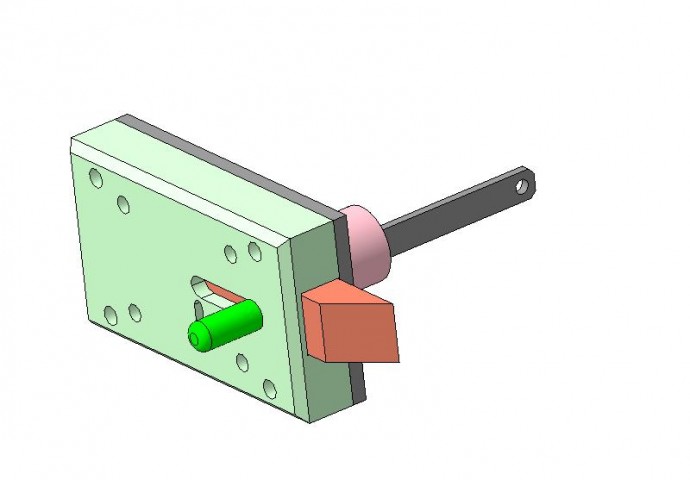

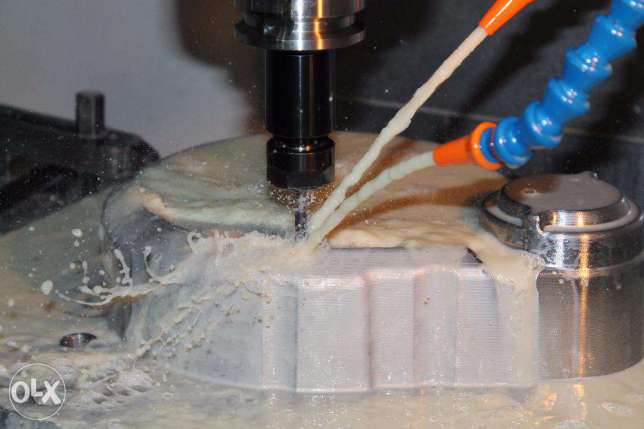

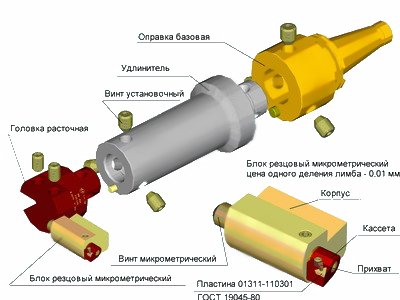

A distinctive feature of the design of the stands is that the stands are equipped with a printing device and hydraulic adjustable clamps of the damper heads, controlled incl. pedals, ambient temperature control, remote control of the temperature of the recuperative chamber of the dampers and the working fluid of the stand's pumping station. The stands allow, in addition to the ability to monitor the tested parameters of the damper and display them on a monitor and a printing device, to diagnose dampers, identify and recognize faults in the damper, their nature and give hints to the operator about the necessary actions to eliminate these faults, as well as accumulate and store information on a hard drive. computer disk. In addition, the stand provides the ability to take into account the reliability of dampers from various manufacturers. The design of the stand minimizes, in comparison with crank mechanisms, the number of rubbing mating surfaces, since hydrostatic circuit diagrams of the mechanisms and Teflon seals are used. This ensures a significant service life, and in combination with a modern element base of electronic systems, high reliability of the design as a whole is achieved.

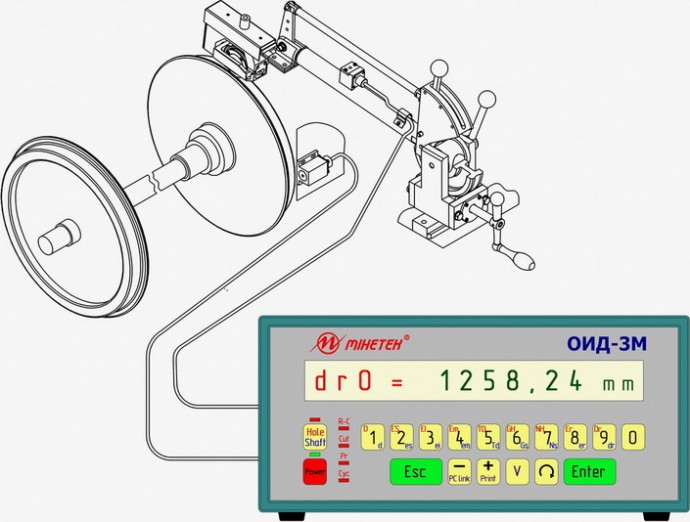

In addition, unlike stands from other manufacturers, the error of measurement systems for controlled parameters of dampers does not exceed: for movement – 0.2%; for force – 0.5% ÷ 1.0% (in the force range 8 ÷ 25 kN). This makes it possible to use these stands as certification equipment for the acceptance and certification of hydraulic vibration dampers.

The method for diagnosing vibration dampers, as well as the design of the stand, are protected by Ukrainian patents No. 72048 UA and No. 72280 UA.

Video of the work of the stand for testing vibration dampers of wagons and locomotives

Stand calibration video

en

en ru

ru uk

uk