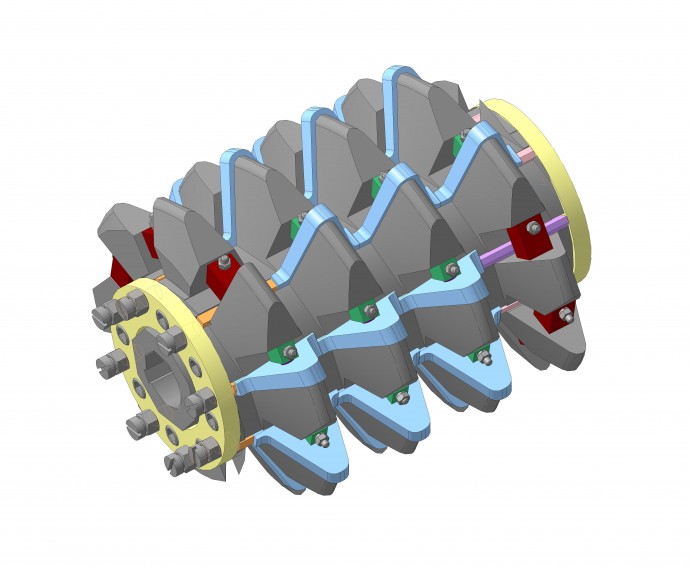

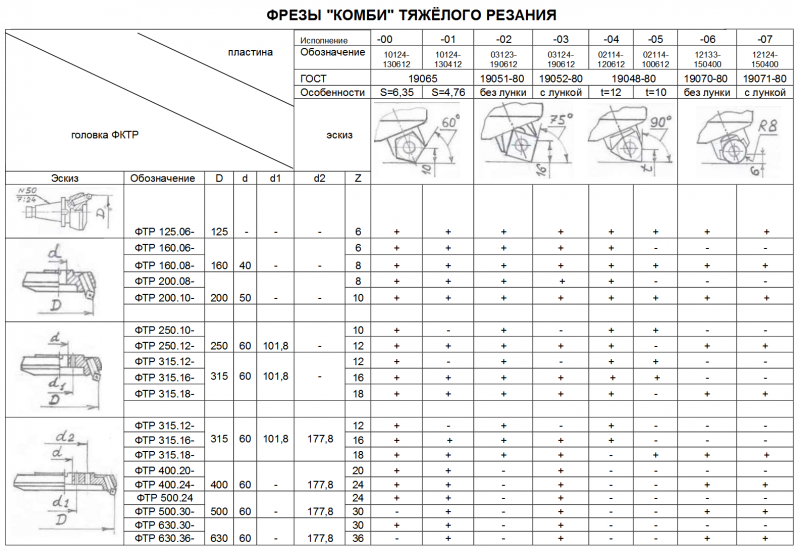

COMBI cutters for heavy cutting

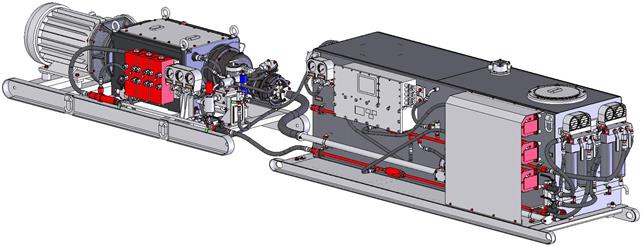

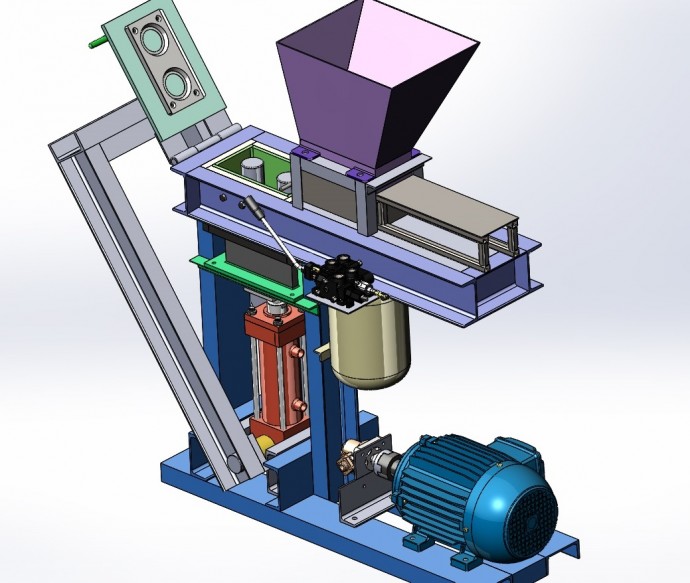

With these cutters you will solve the milling problems at your plant.

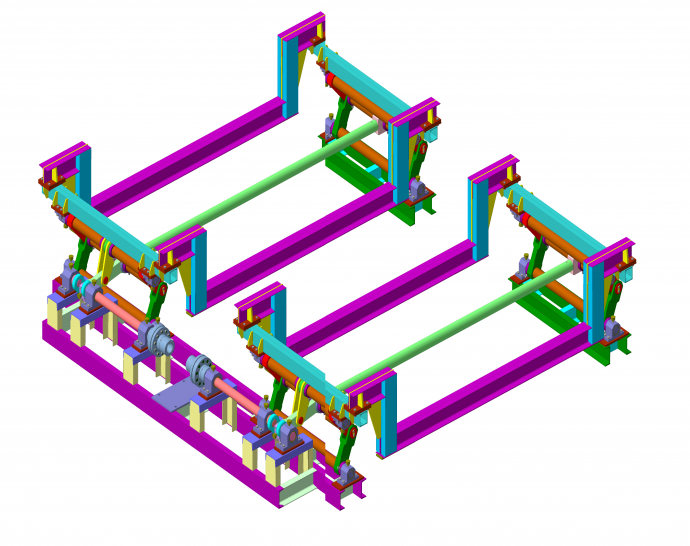

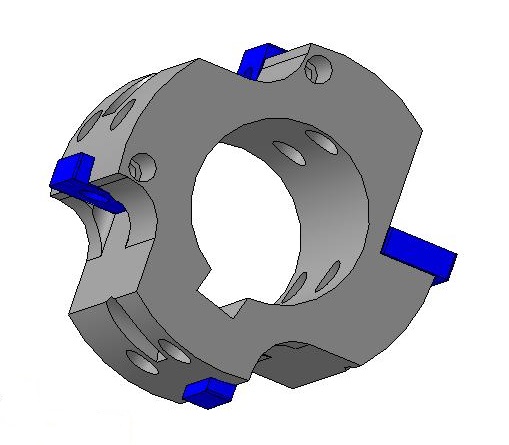

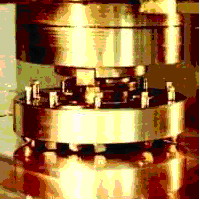

Versatility (combining the milling head with knives of various technological purposes), the minimum beating of the cutting edges (compensation of the beating of the cutting edges during tuning), increased stiffness, vibration resistance, reliability (the choice of milling cutters for diameter, number of knives, cutting geometry), high maintainability (cutting part is taken out for the case), high productivity and convenience in work.

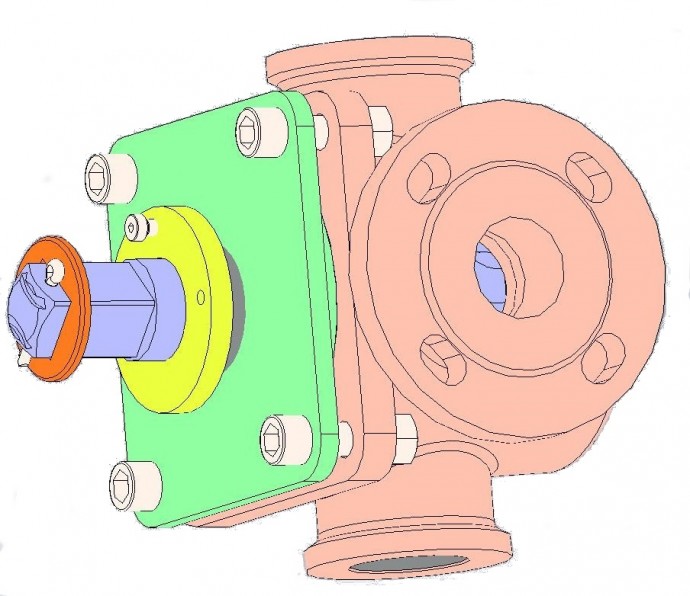

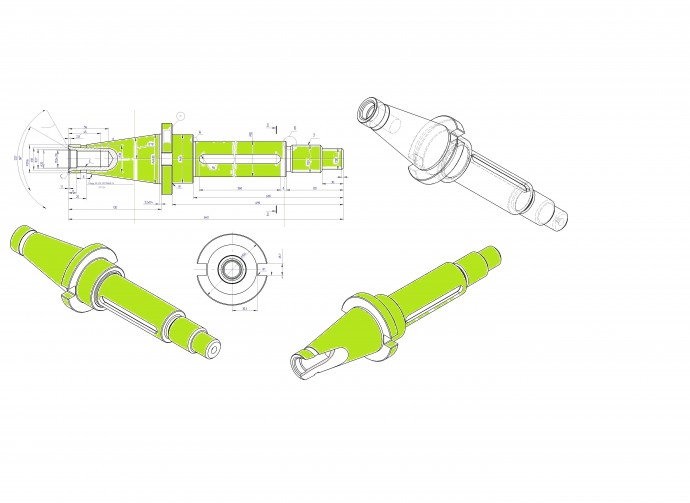

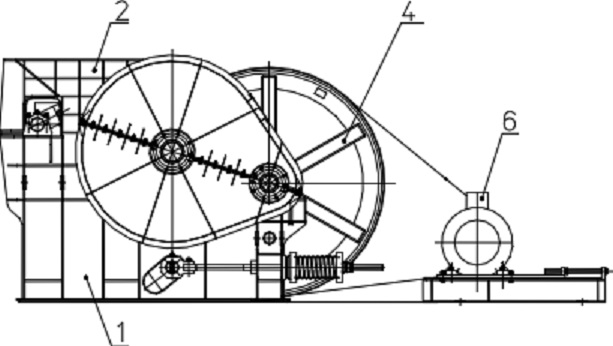

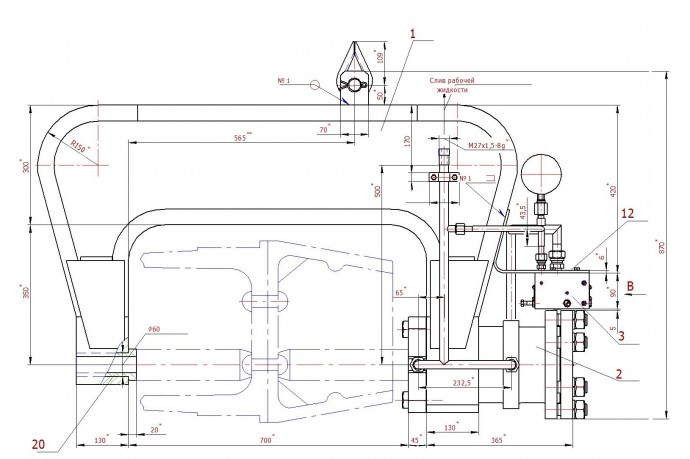

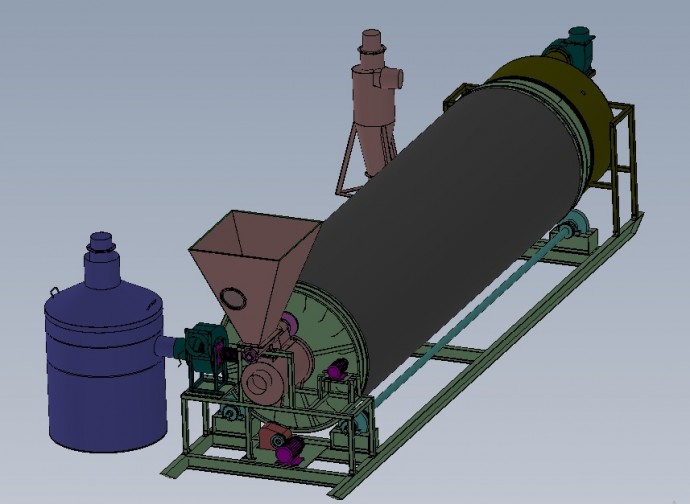

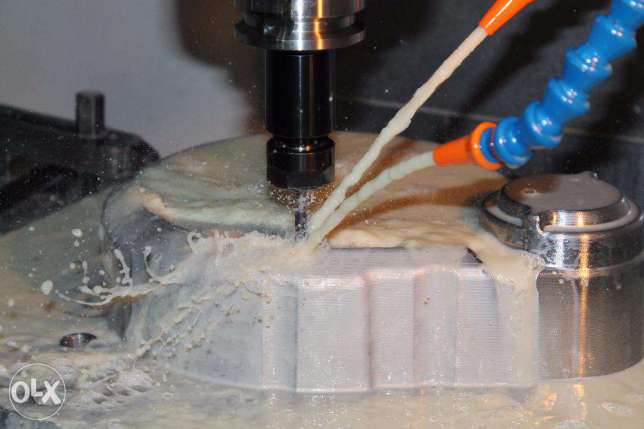

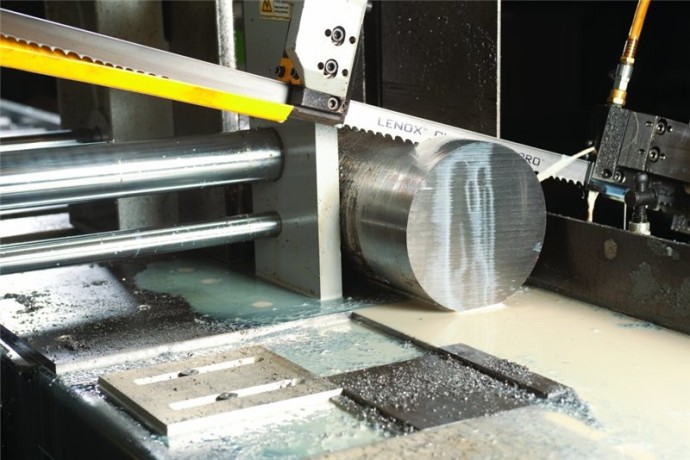

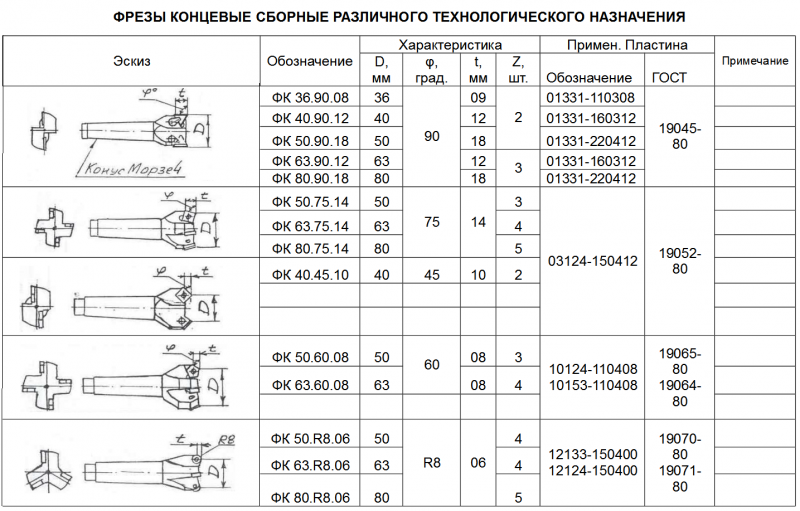

They are intended for use on machines of a milling and boring group with a drive power of 10-80 kW, in the processing of steel (Z min) of cast iron (Z max), for milling the jaw (φ = 60˚, φ = 75˚), for milling the ledges (φ = 90˚), surfaces on the crust (Z min), finishing milling (R8).

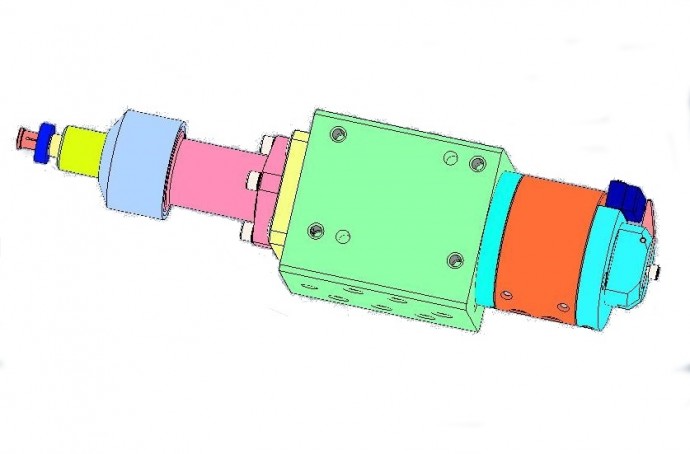

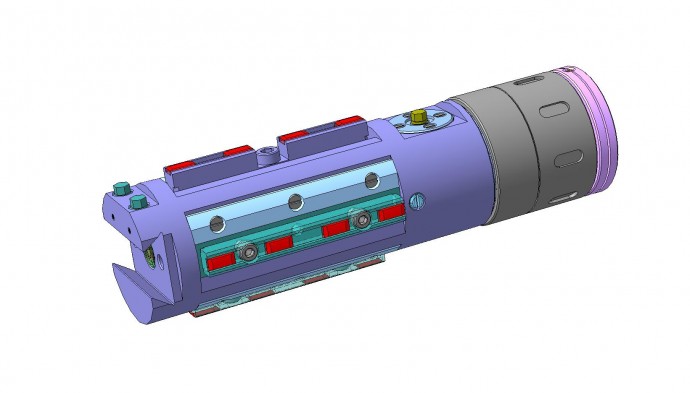

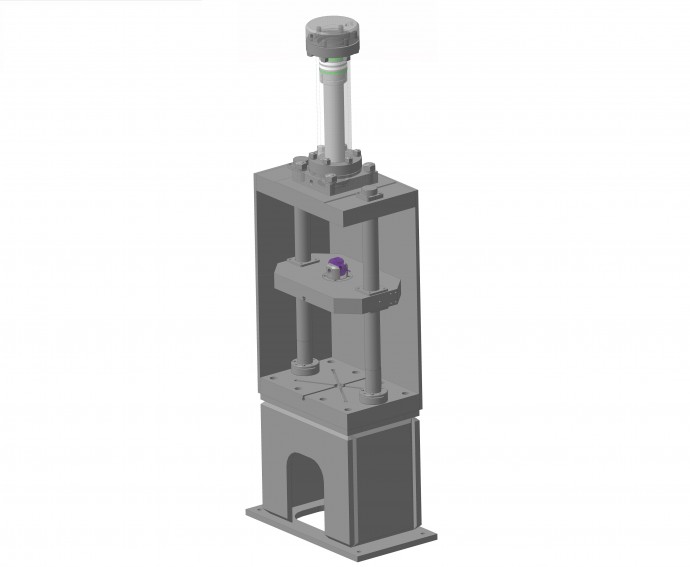

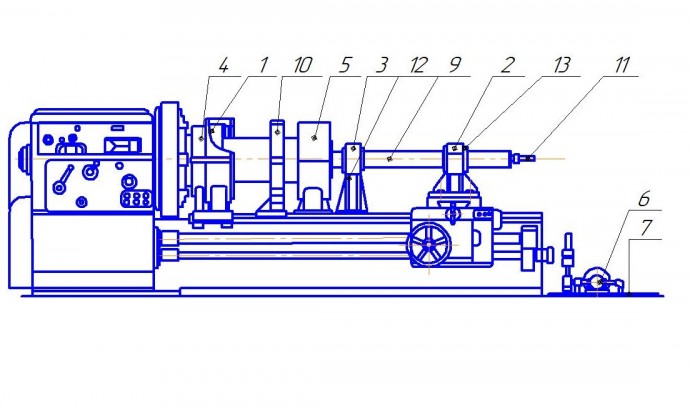

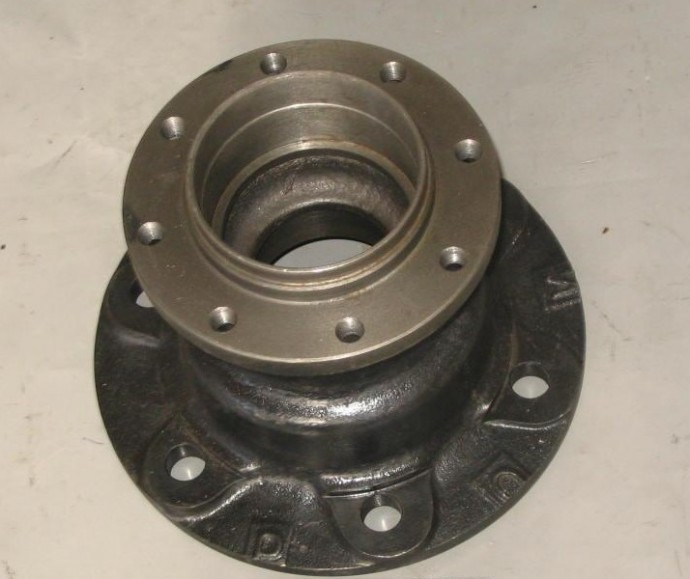

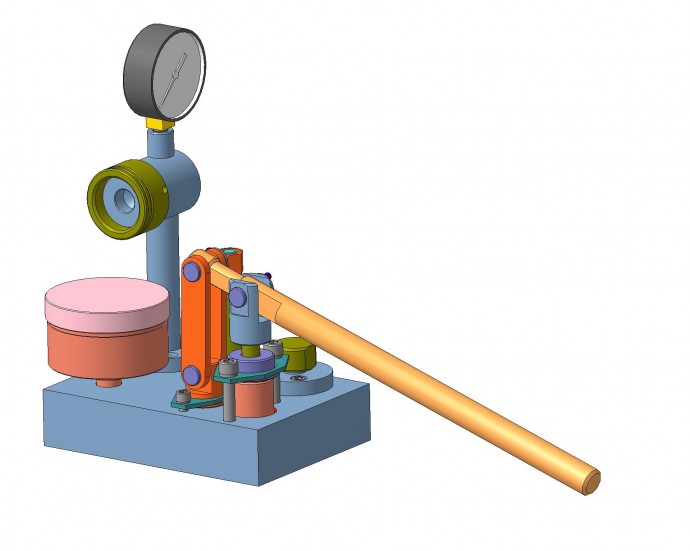

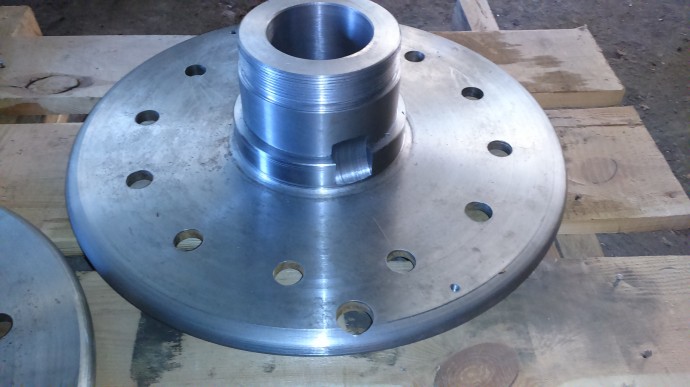

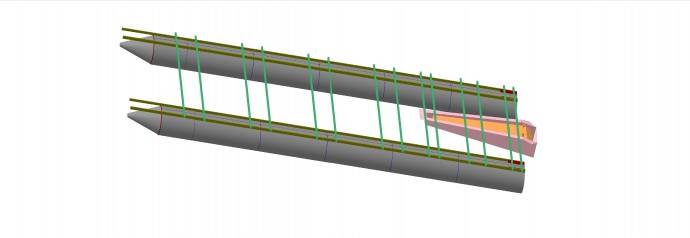

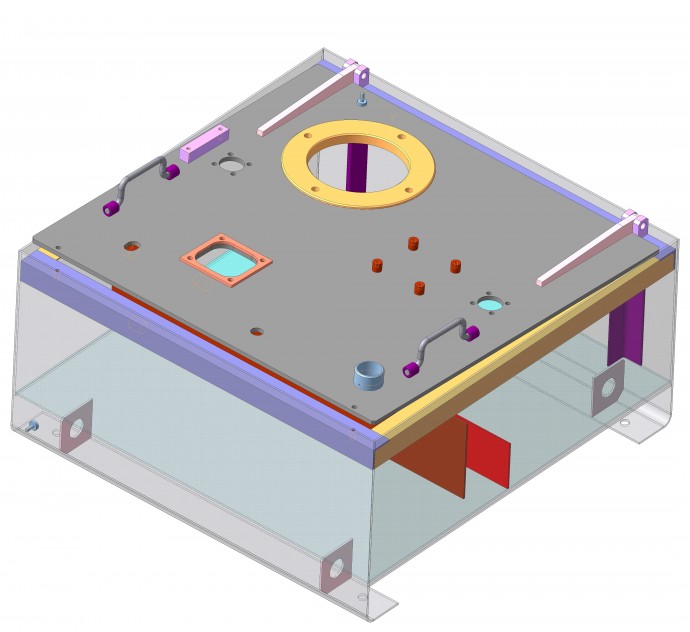

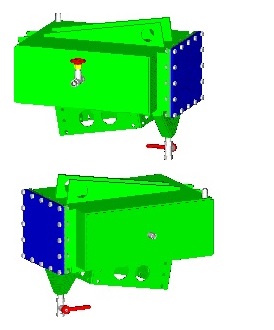

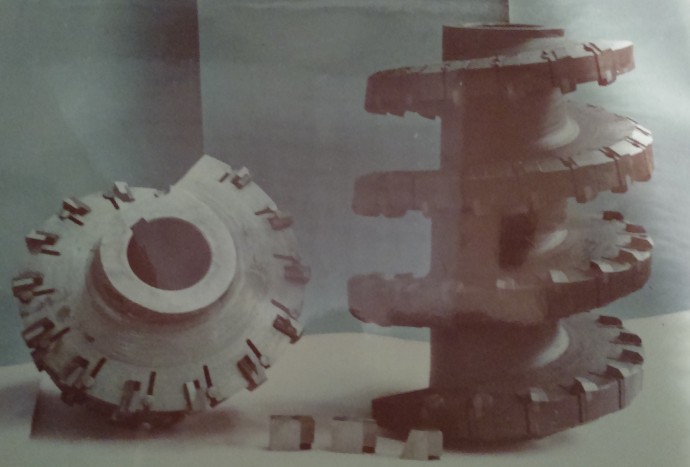

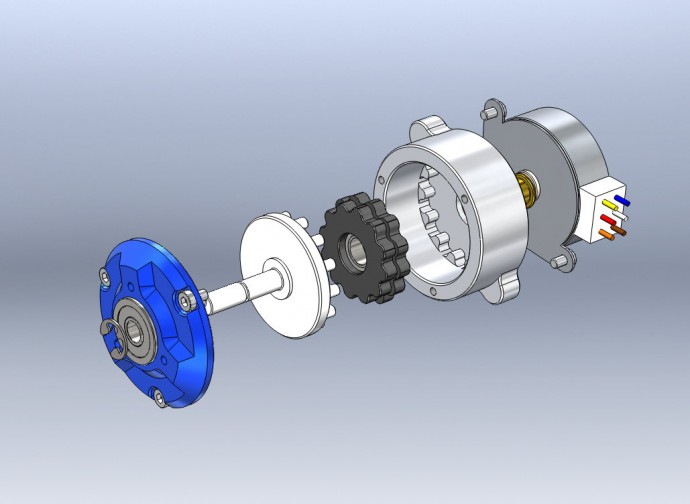

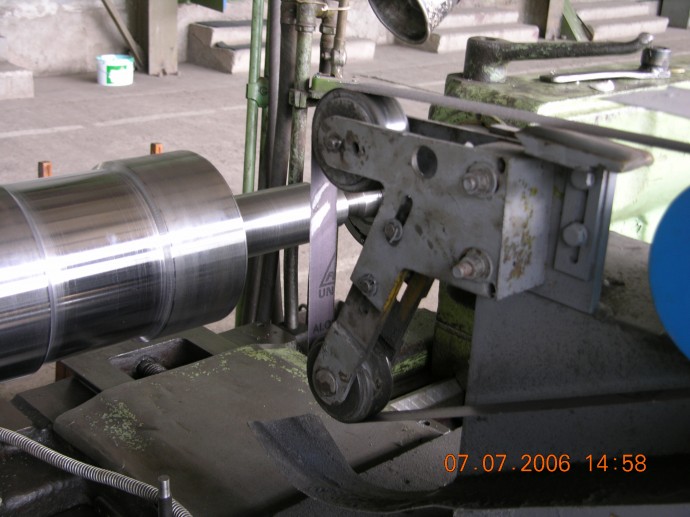

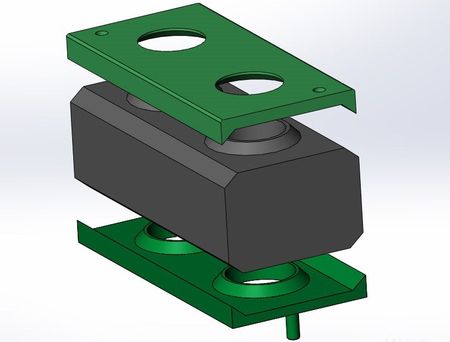

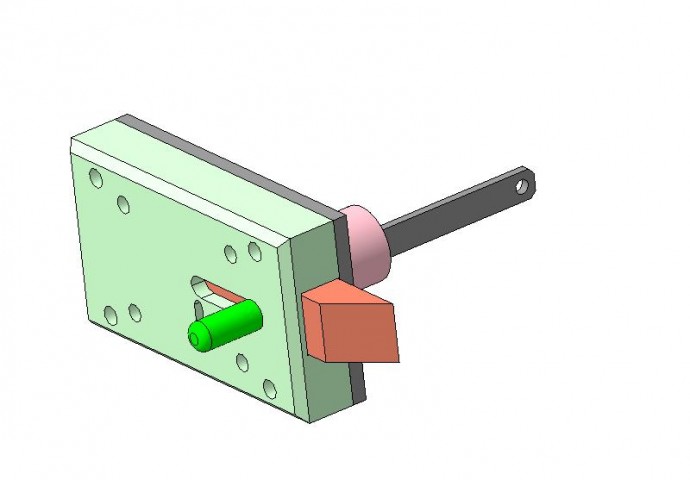

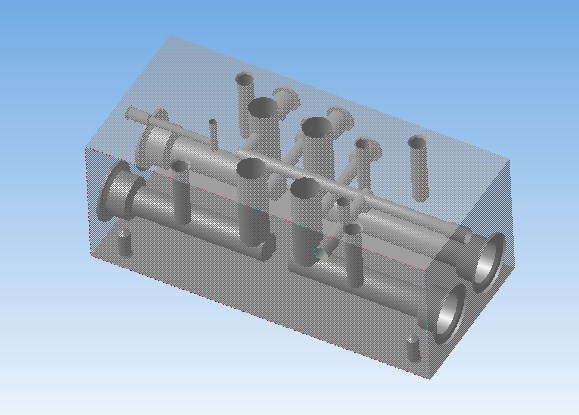

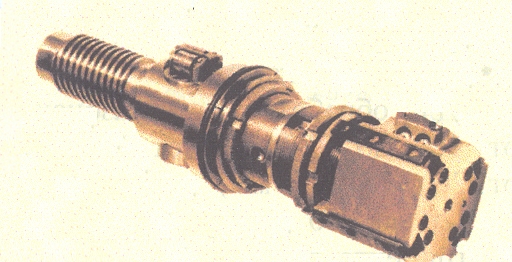

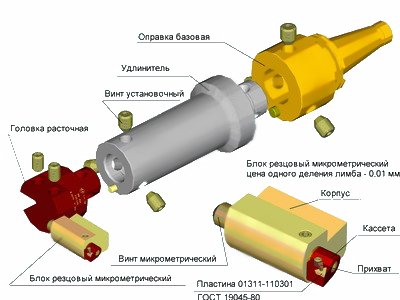

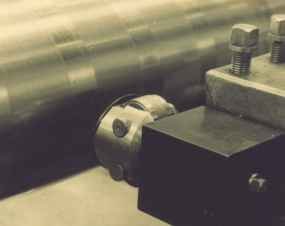

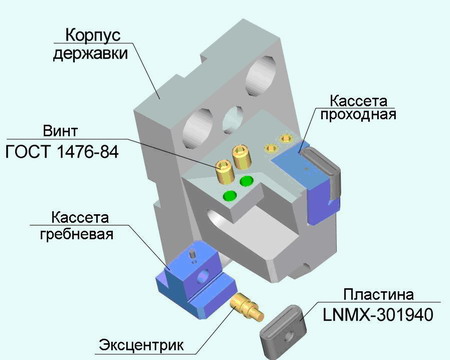

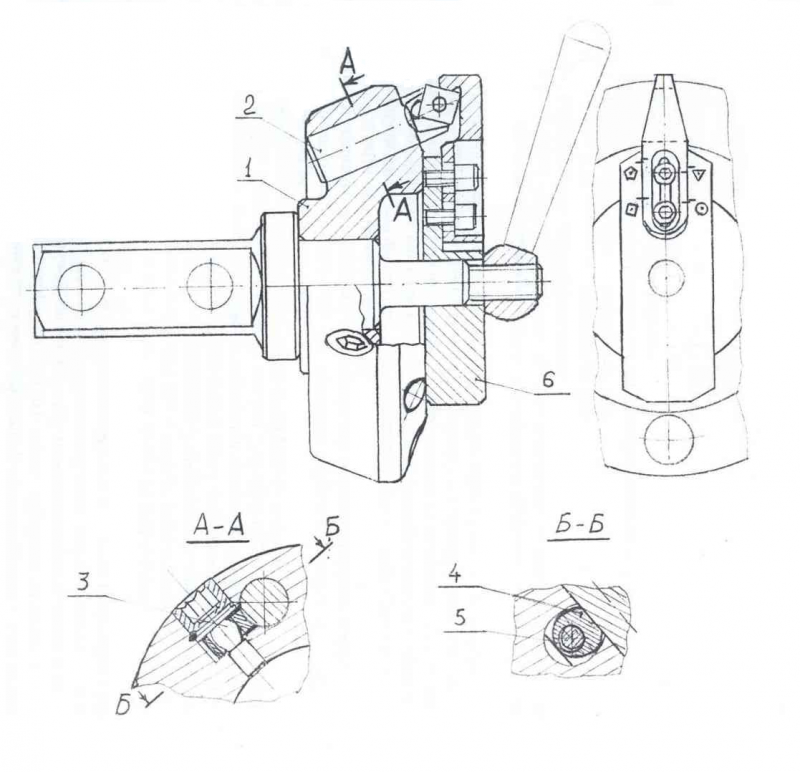

The cutter consists of a head and a set of one of the designs. The head is a body 1 (see sketch and table) with intersecting cylindrical holes for knives 2 and eccentric 3 fastenings). In the hole for the eccentric T-trimming cutter a pocket is made for the biscuit 4, covering the radius of the knife body.

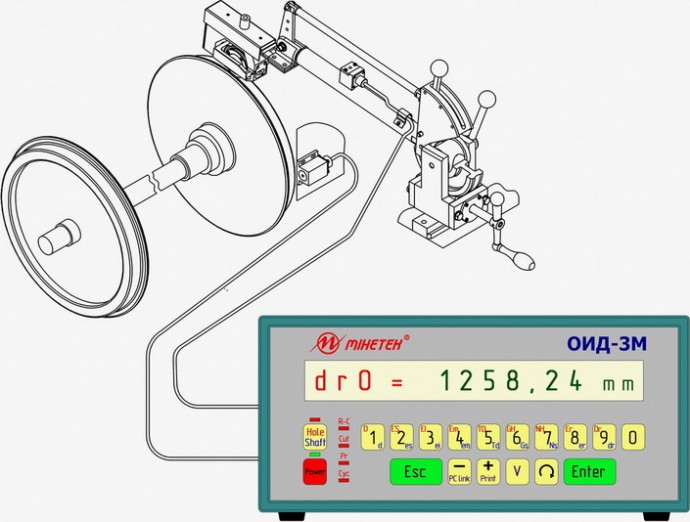

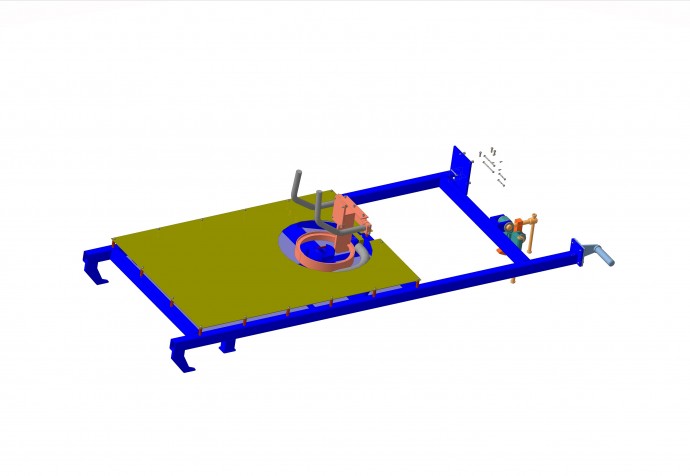

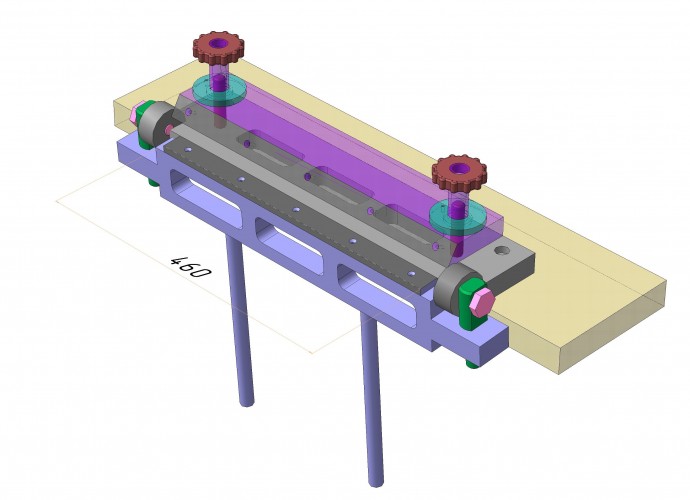

In an unsecured position, the biscuit is always compressed by a flat spring 5 onto the knife, and the knife is clamped by the support surface onto the opening of the milling cutter body. This ensures that when setting and fixing the knife, there is no displacement of the cutting edge adjusted by the conductor. Adjustment of the mill is carried out mainly on the conductor 6.

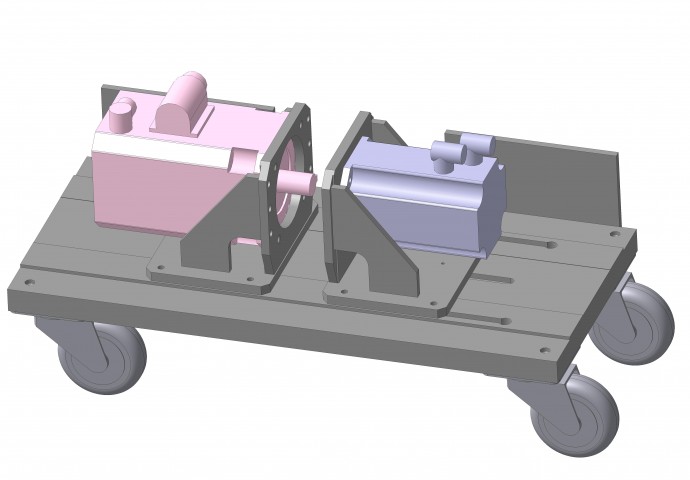

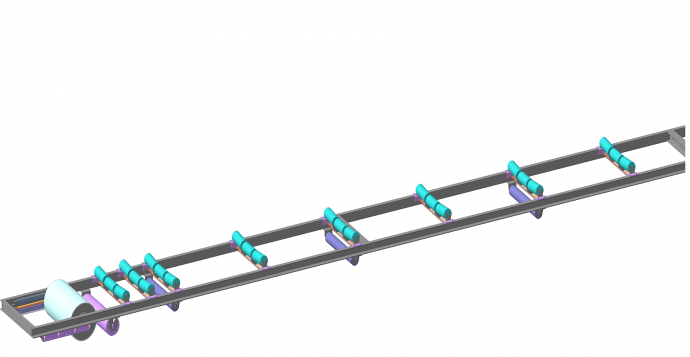

Different number of holes for knives (Z) will allow to choose the optimal head for processing continuous and discontinuous surfaces of products made of steel and cast iron, to ensure full loading of the machine in terms of power and rigidity.

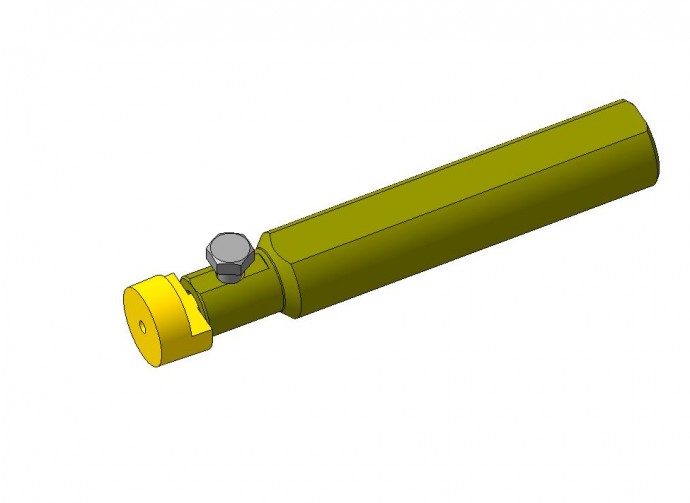

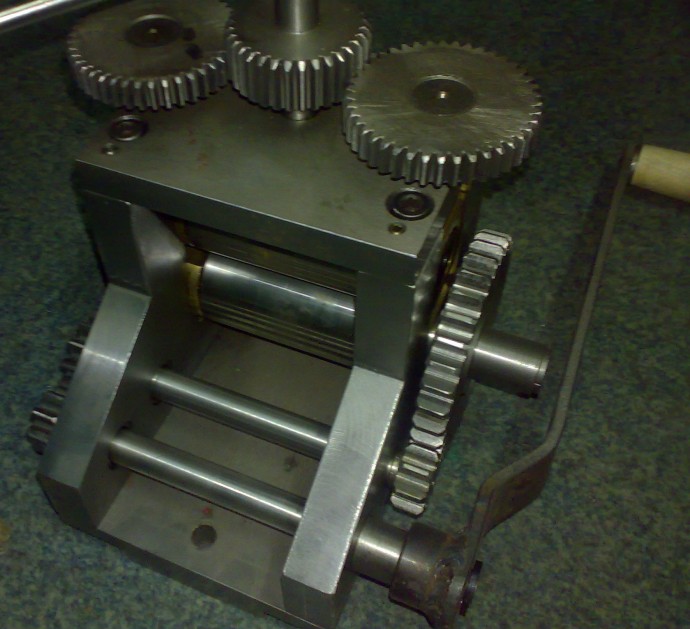

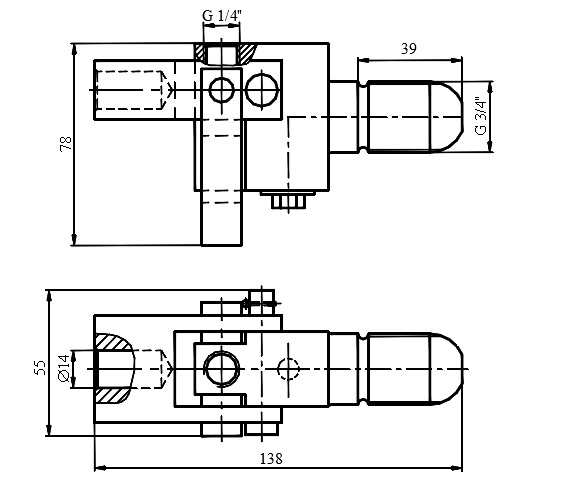

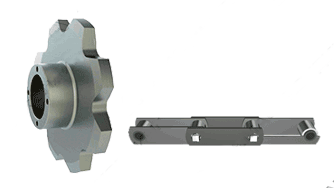

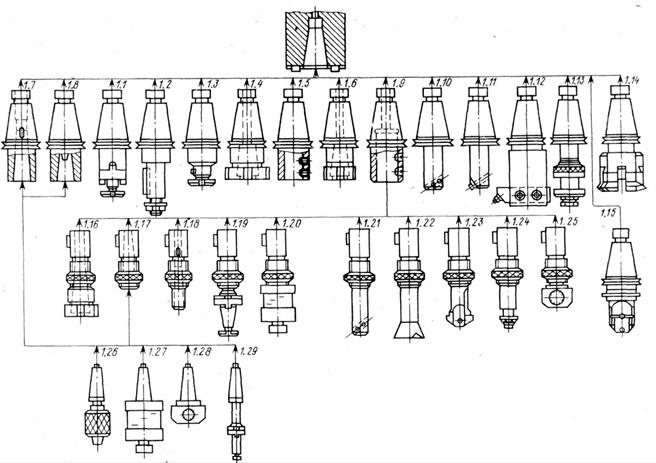

Knives of cylindrical shape (d = 25 mm) with mechanical fastening of replacement plates of various shapes and sizes (version). At the request of the customer, it is possible to equip the knives for other plates.

Depending on the material of the workpiece, the surface quality of the workpiece, the requirements for the machined surface, the machine's power, the rigidity of the workpiece, a set of blades of one of the versions is selected.

Example of ordering two milling cutters with a diameter for machining discontinuous surfaces on cast iron parts, with an allowance of up to 6 mm, the right version, with knives under the round plate with the maximum number of knives:

Cutter FTR 400.24-07 number 2 pcs.

- Conductor d 400 mm Quantity 1 piece.

Example of ordering a milling head with a diameter of 160 mm, Z = 8 with sets of spare knives for different purposes:

Head FTR 160.08 - 1 pc.

Knife isp 01 - 16 pcs. (2 k-ta)

The knife isp. 03 - 8 pcs. (1 k-t)

Knife isp 05 - 8 pcs. (1 k-t)

Knife isp 06 - 8 pcs. (1 k-t)

Conductor d = 160 mm - 1 pc.

en

en ru

ru uk

uk