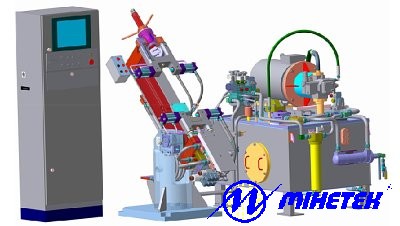

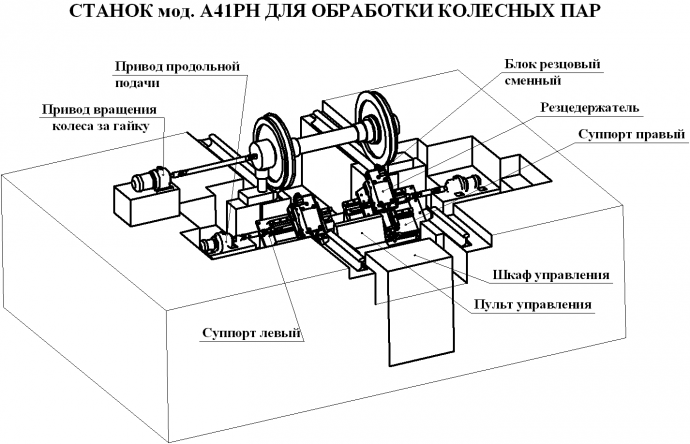

Modular system of cutting tools and equipment for machines

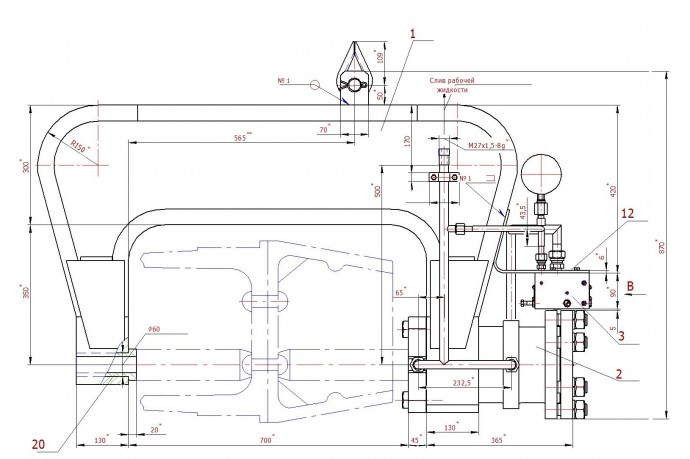

A modular system of cutting tools and auxiliary equipment is designed to reduce the range of equipment and auxiliary time, as well as to improve the equipment's equipment in the operations of milling planes, drilling and boring holes on horizontal boring machines.

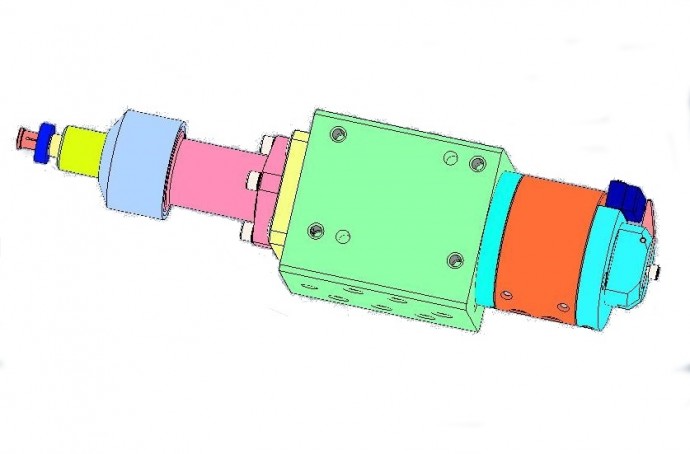

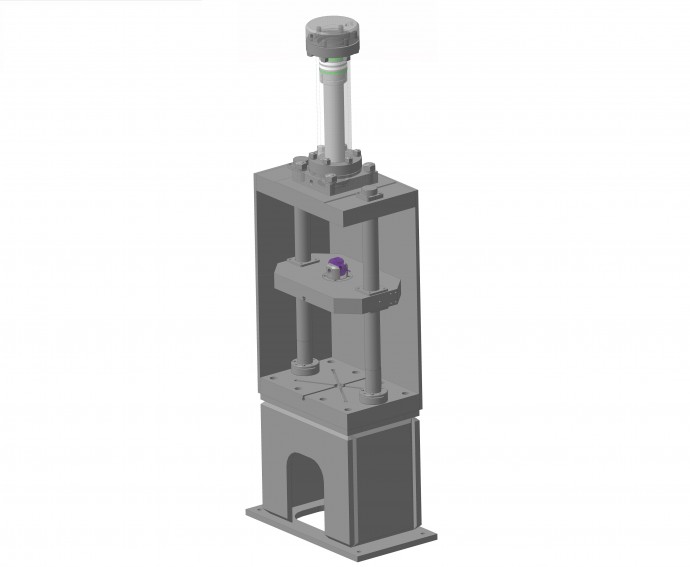

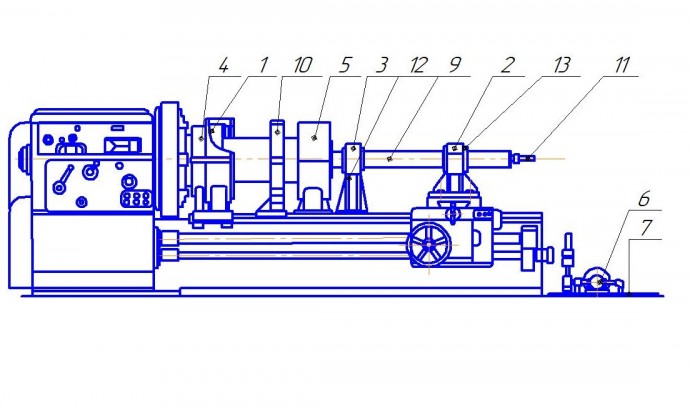

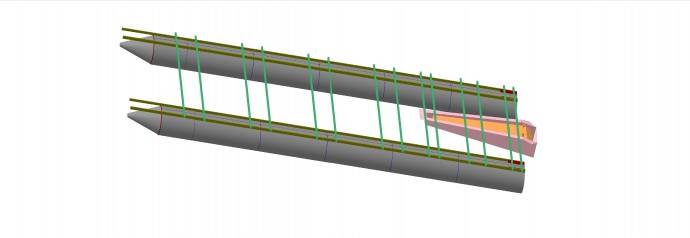

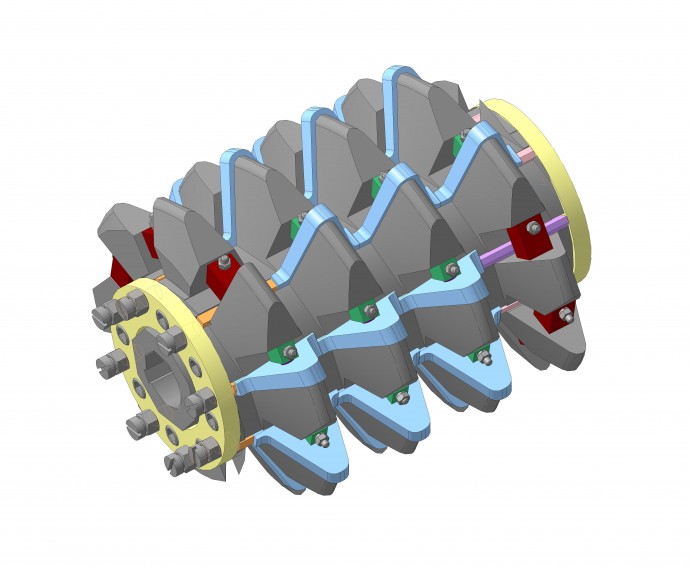

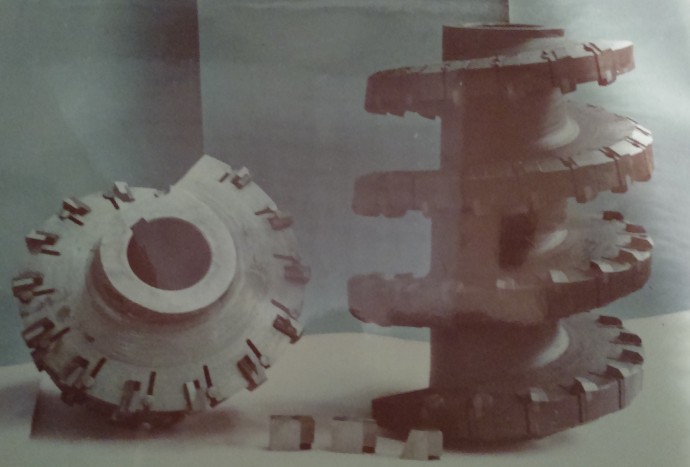

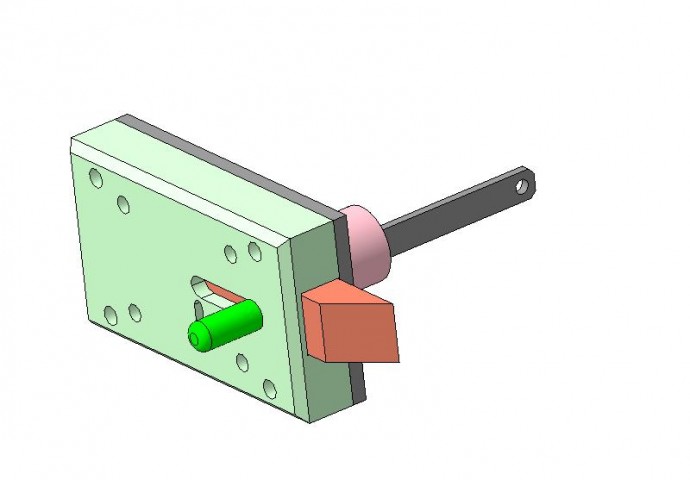

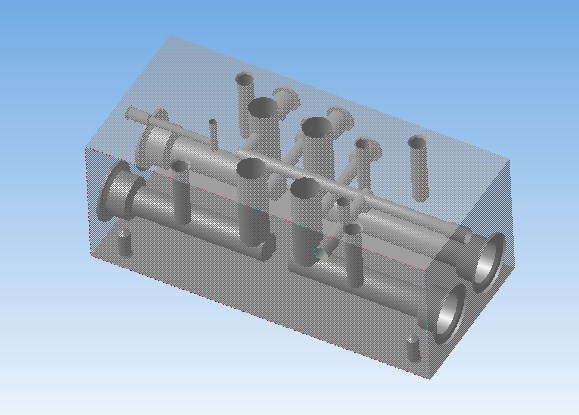

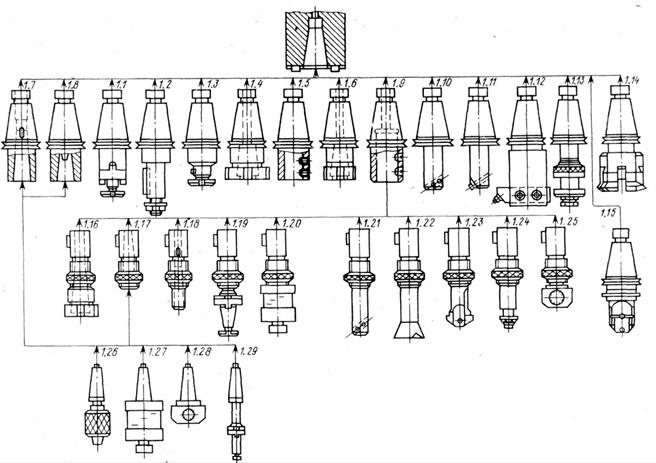

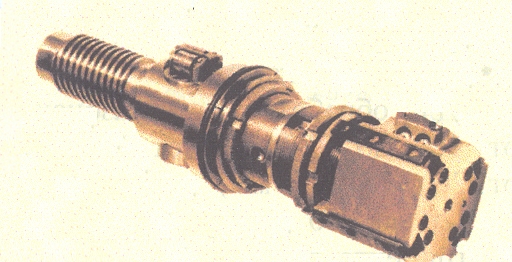

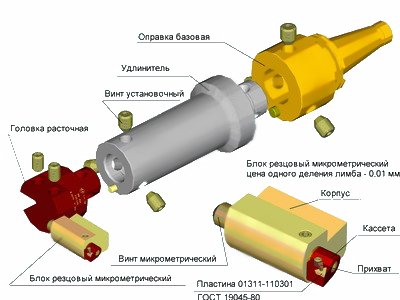

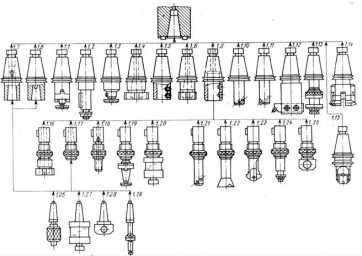

The structurally modular system according to Fig. 1 consists of basic mandrels 1 - 4, adapters 5 - 20, mandrels 21 for installing countersinks, countersinks and reamers, cartridges 22-25 for fastening drills and end mills with cylindrical shanks, boring heads 26-30 and cutting tool 31 - 59.

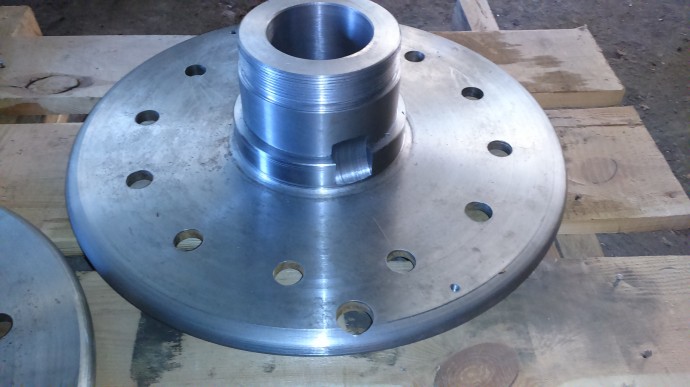

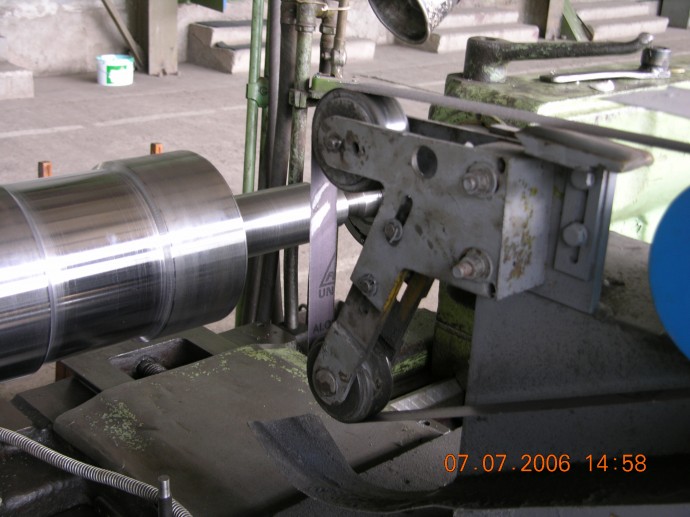

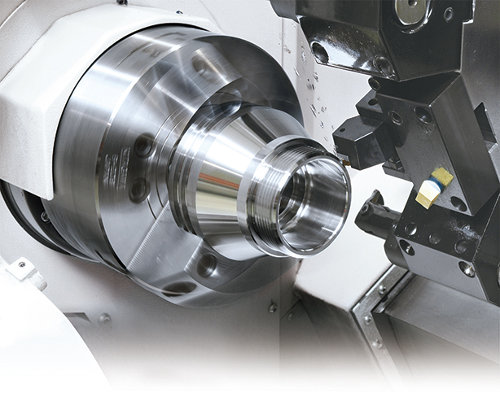

Basic mandrels are installed in the spindles of horizontal boring machines. Structurally, the base mandrels have, on the one hand, a connecting cone corresponding to the tapered hole in the spindle, on the other hand - a flange with a docking assembly for fixing either adapters or face mills and boring heads. The design of the module connection unit ensures fast tool change, is reliable in operation and is not inferior in rigidity to the integral tool. For one horizontal boring machine there are several mandrels with the same connecting cone, but having different sizes of the flange with the docking assembly, which allows processing of planes and holes in a wide range. Depending on the design of the workpiece to be processed and the forthcoming processing operation, the installation and fixing of specific components of the system that allow this operation to be carried out into the base frame.

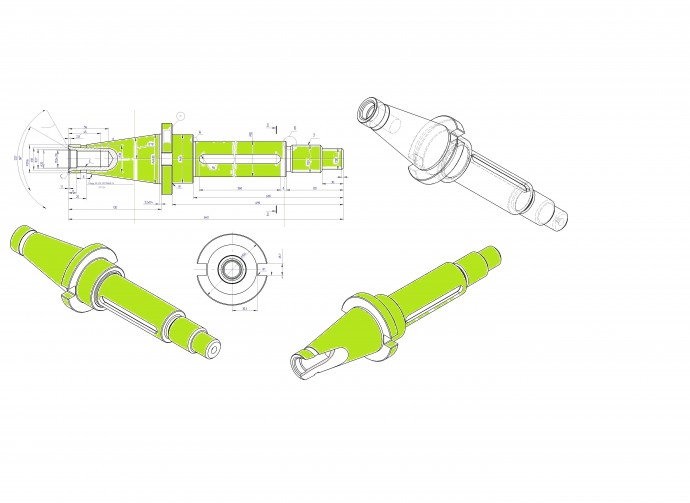

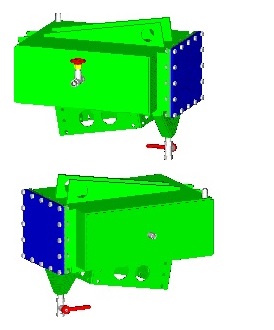

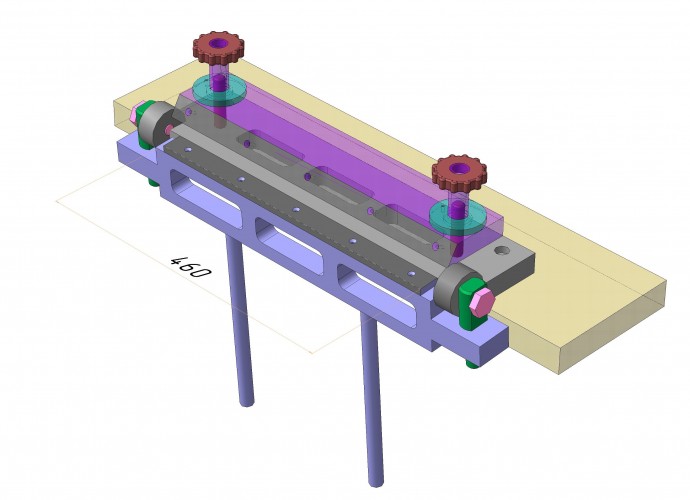

Adapters and cartridges are the connecting links between the base mandrels and the cutting tool and are designed to accommodate and secure the end mills

44 - 50, boring heads 26 - 30 and end tools 37 - 43. In boring operations, adapters are used in cases where the depth of the holes does not exceed the total length of the adapter and boring head, and also in those cases when the diameters of the holes being treated are either smaller the outer diameter of the spindle, or exceed it by an amount not exceeding 40 mm. The processing of such holes must be made with boring heads with a lower range smaller than the outer diameter of the spindle.

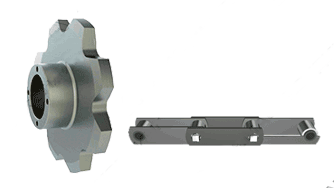

For machining holes for fastening threads, the system has transition sleeves 7 and 8, adapters 9-14. Adapters 9 and 10 fix drills 38, countersinks 30 and reamers 40 with conical shanks.

For fastening drills 37 and milling cutters 41 with cylindrical shanks, chucks 22, 23 and 24, 25, respectively, are provided which are attached to adapters 11, 13 and 12, 14. Mills for processing T-shaped grooves, end mills 43 and end mills 44 with conical shanks installed directly into the adapters 11 - 14.

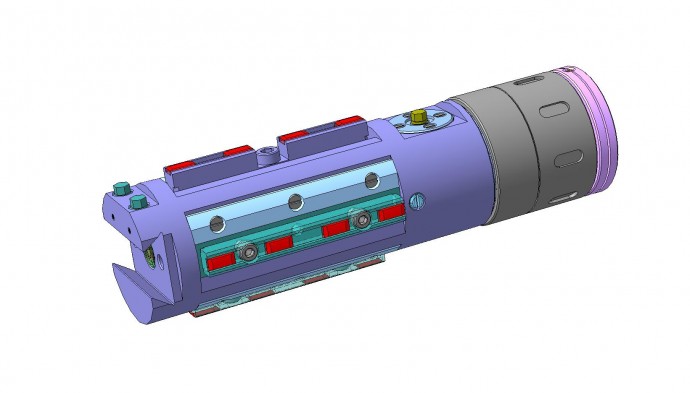

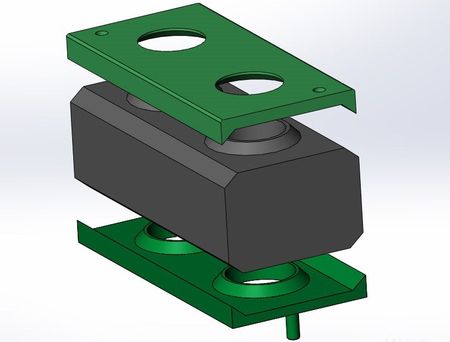

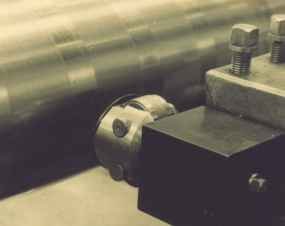

For boring and finishing of holes for installation, for example, shafts, bearings, etc., boring heads 26 - 30 are provided in the system, in which either standard boring cutters 31 and 32 or inserts 33-35 with micrometric adjustment for size are installed. Cutting elements 36 of inserts with micrometric adjustment are made interchangeable and have various functional purposes, which allows performing boring operations on the pass, at the stop, for chamfering both in straight walls and in reverse ones.

For finishing machining of holes 7 of quality with roughness Rа 1,6 - 0,8 mkm floating sweeps 60 - 62 are provided, which, depending on their diameter, are installed in cases 63-66.

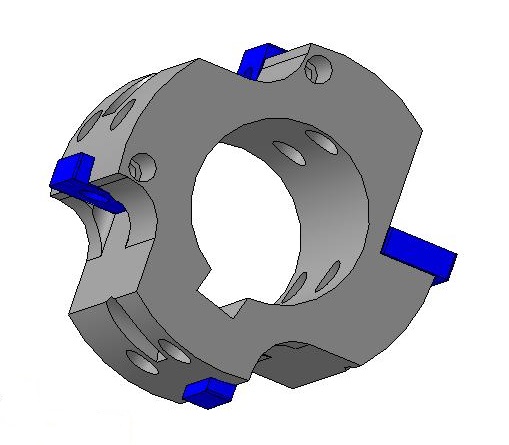

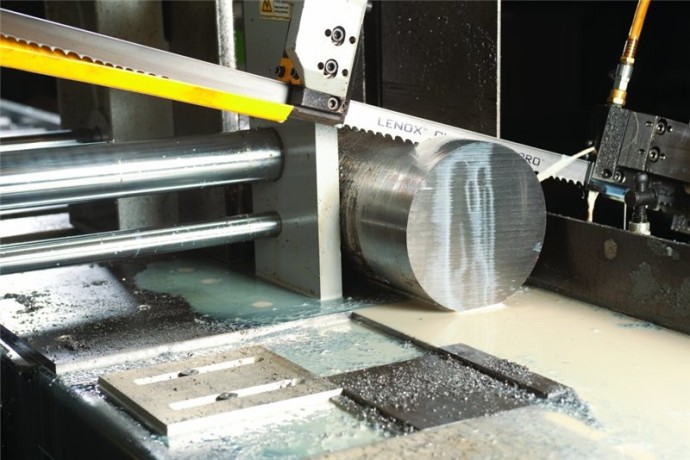

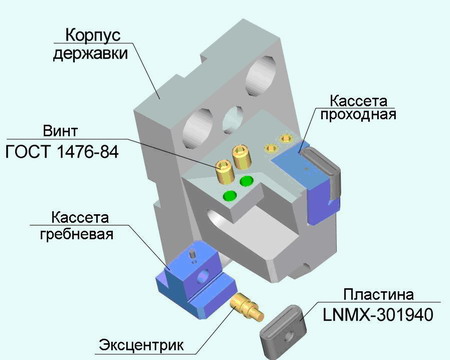

For machining planes, face mills 45 - 53, depending on their diameter, are installed either directly into the base mandrel or through an adapter. End mills can be equipped with replaceable 57 cylindrical knives of various functional purposes for milling of open surfaces (φ = 45º and φ = 60º) and surfaces with ledges (φ = 90º). Replaceable multi-sided hard-alloy plates are fixed to the knives 57 by means of eccentrics. To eliminate the beating, the cutting edges of the plates are set either by the processing of one plate or by a conductor.

Disk 58 and tripartite 59 milling cutters are installed on adapters 15 - 18.

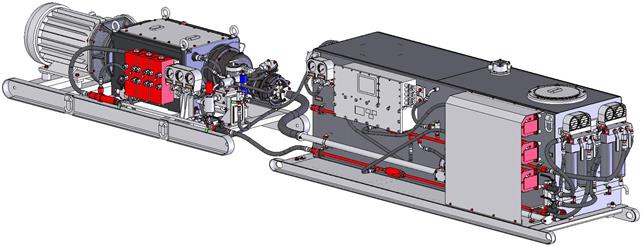

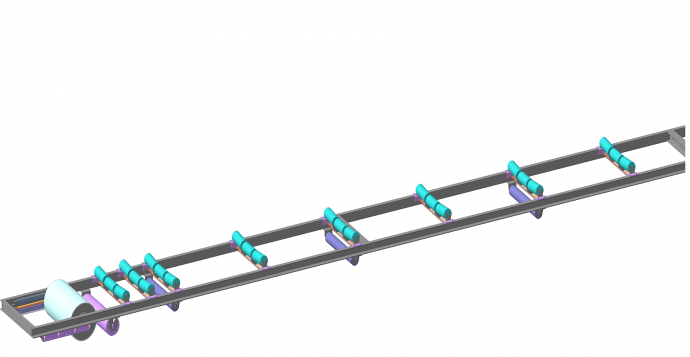

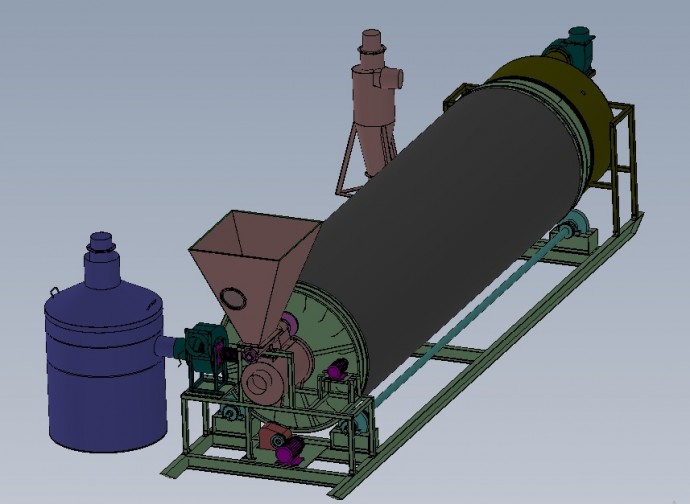

Modular system of cutting tools and auxiliary equipment for longitudinal milling machines

For longitudinal milling machines, a large part of the modular cutting tool and auxiliary equipment system is used for horizontal boring machines - mandrels 2 and 4, adapters 5-20, cartridges 22-25, end mills 44 with interchangeable multi-sided carbide plates, which are fixed directly on the body of the milling cutter, end 45 - 53 with replaceable

knives 57, disc milling cutters 58 and tripartite 59, end tools 37-43, and boring tools 26-35.

The modular system for longitudinal milling machines is supplemented with end mills 54 - 56, which are mounted and fixed directly on the spindle of the machine.

Modular system of cutting tools and auxiliary equipment for vertical milling machines

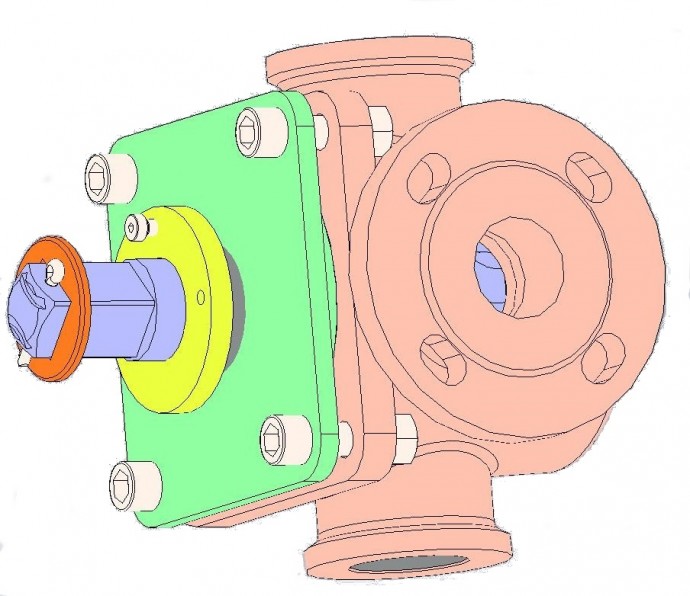

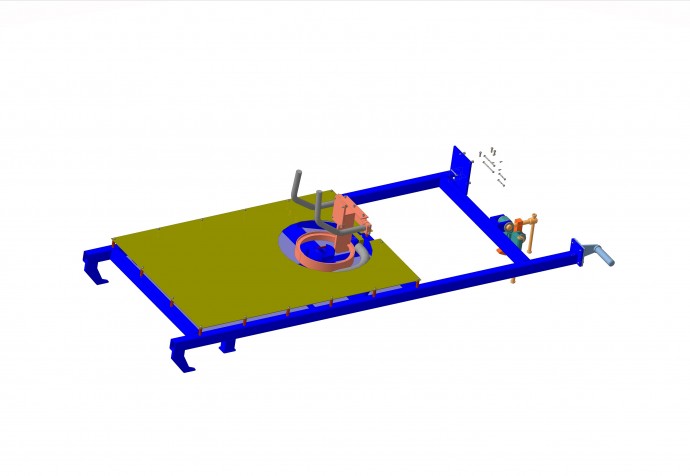

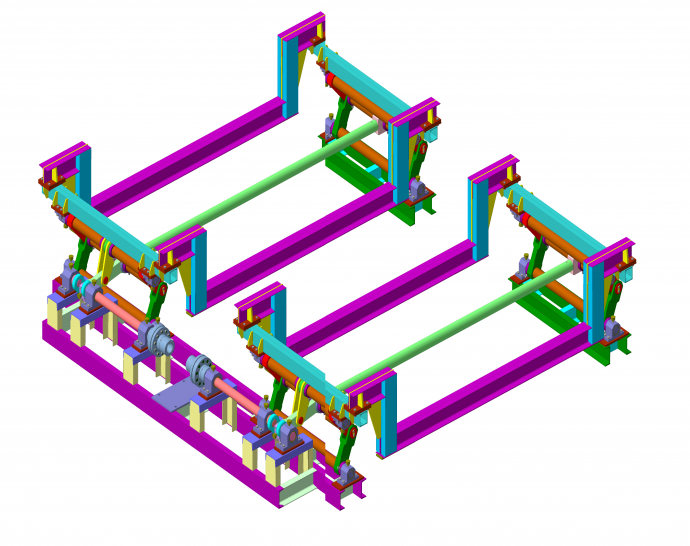

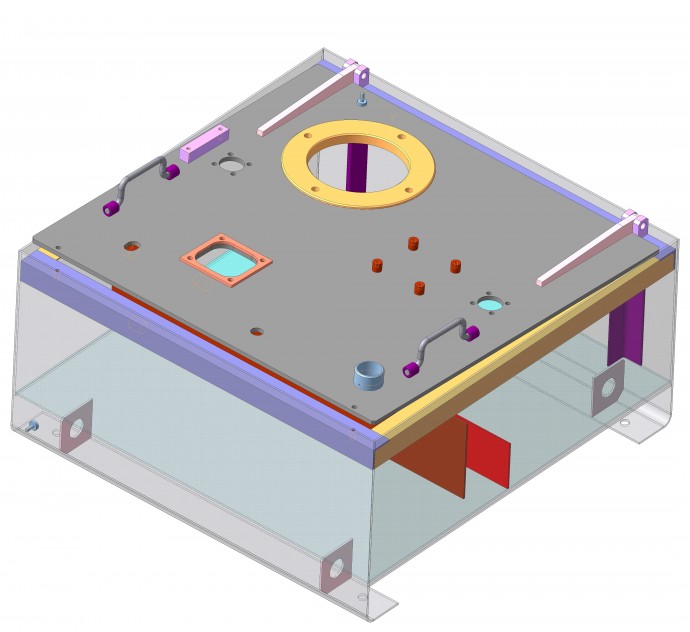

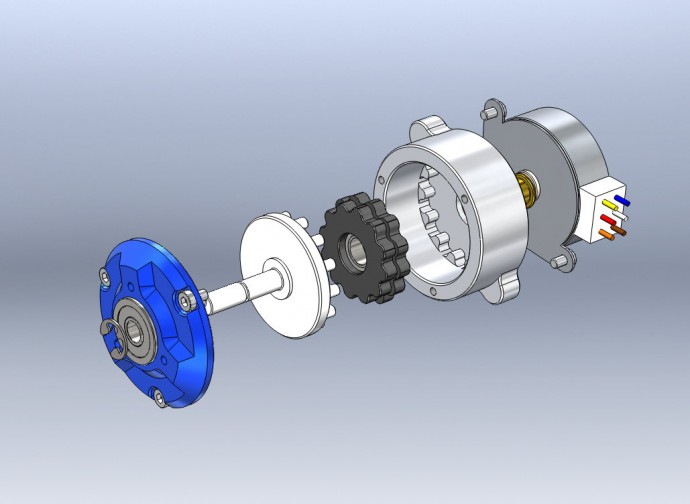

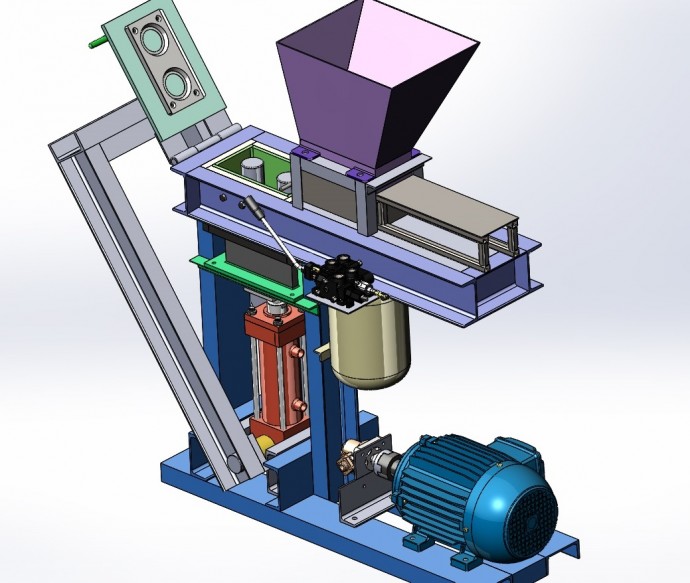

Modular system of cutting tools and auxiliary equipment for vertical milling machines is built on the use of a free-standing attachment.

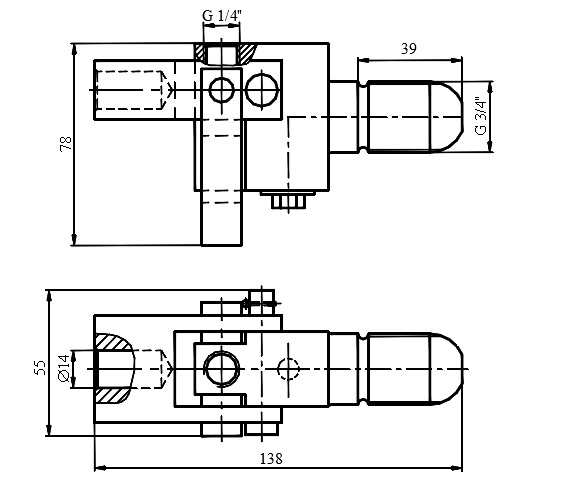

The system includes auxiliary equipment: mandrels 1 with an internal cylindrical hole, mandrels 2 with inner Morse cones, mandrels 3 with cylindrical shanks and an end key, mandrels 4 and 5 with cylindrical shanks and axial prism keys, collet chucks 6, cartridges 7, mandrels boring 8, adapters 9 and transition bushings 10.

The listed set of auxiliary equipment allows fixing end mills with a conical shank 11, end mills with a cylindrical shank 12, milling cutters for processing T-grooves 13, milling cutters 14 and 15 with conical shanks, end milling cutters 16, disk milling cutters 17 and cylindrical 18, as well as drills 19 and 20.

The end mills 14 are equipped with replaceable multi-sided carbide plates 21 of various shapes, which are fixed directly to the body. To expand the technological capabilities of the milling cutters, end 15 are equipped with replaceable cylindrical knives 22, on which are attached replaceable multi-sided carbide plates of various shapes. (Figure 3)

en

en ru

ru uk

uk