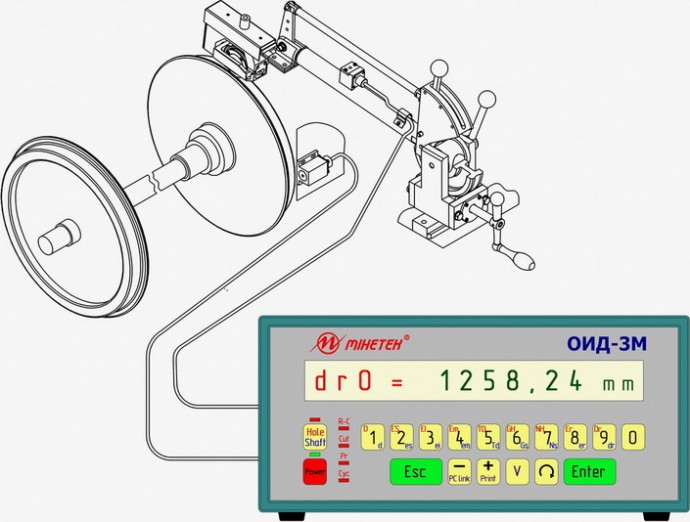

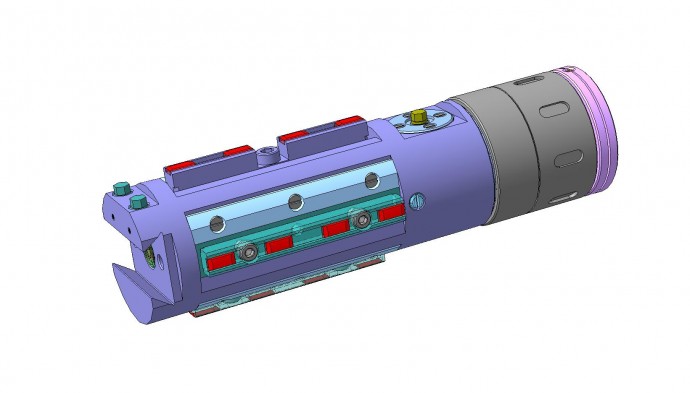

ETM-01 Compact electronic hardness tester

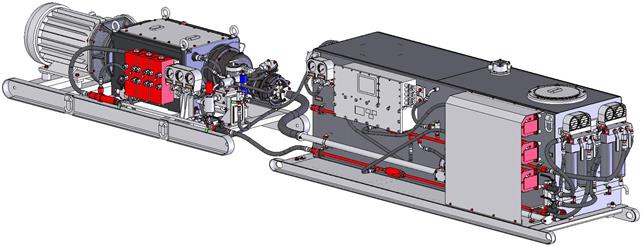

Electronic small-size hardness tester ETM-01 in accordance with TU U 33.2-23113534-003: 2008 produced by JSC "MINETEK" passed State acceptance tests and entered in the state register of measuring equipment under No. У 1913-04. To date, this is the only domestic device of this class (certificate No. UA - MI / 1p - 1569 - 2004 of 10.11.04).

The hardness tester is designed for non-destructive testing of hardness of metals in production and laboratory conditions on the Brinell, Rockwell and Vickers scales. The principle of the hardness meter is dynamic. The hardness meter is manufactured in the versions shown in the table.

| Designation of the modification | Execution | Hardness measurement scale | Scale format | Form of presentation of measurement results on the display of a hardness meter |

|---|---|---|---|---|

| ЭТМ-01 | 1 | HB | ХХХ | Conditional units of hardness H. Determination of actual hardness according to calibration tables |

| 2 | HRC | |||

| 3 | HB; HRC | |||

| 4 | HB; HRC; HV |

Features of hardness meter ETM-01:

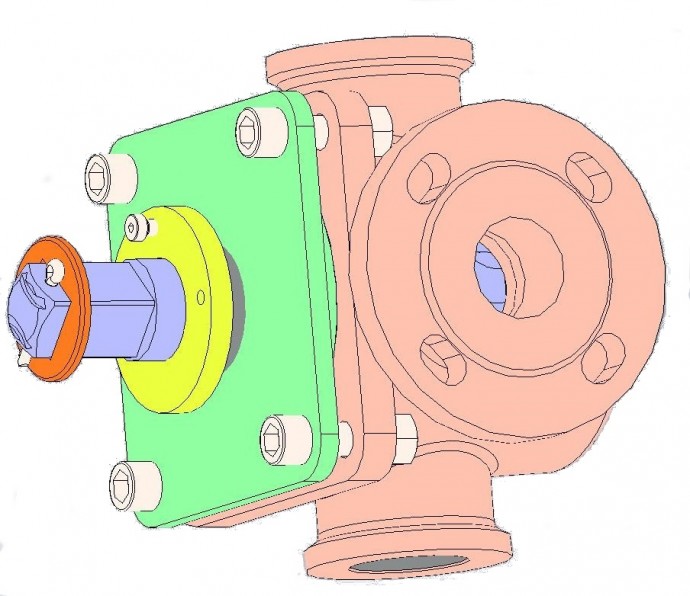

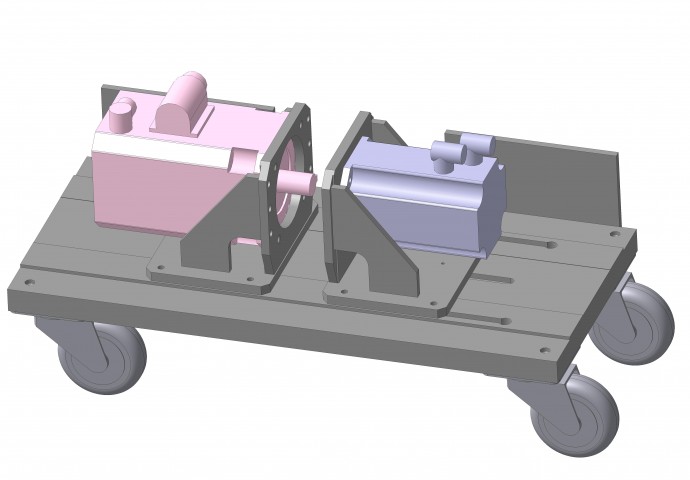

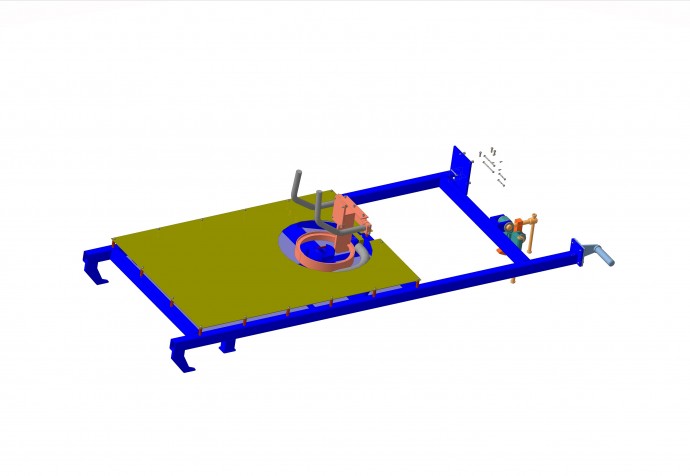

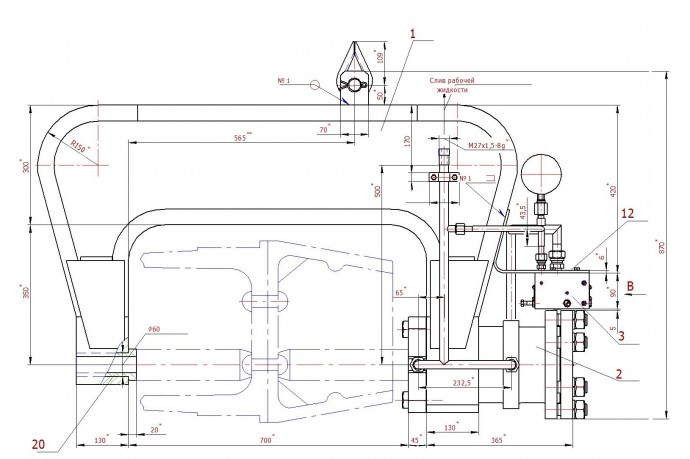

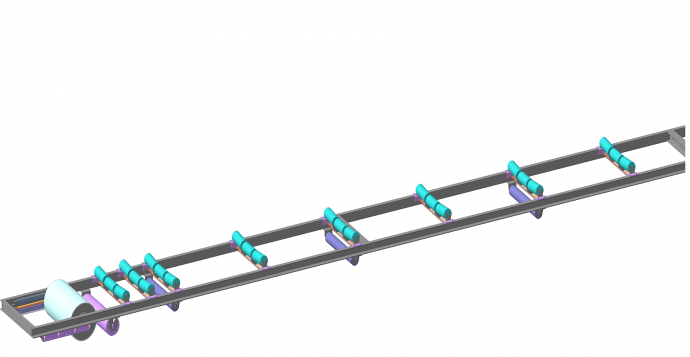

Measuring hardness of complex shape parts and large-sized products having hard-to-reach measurement zones, with different spatial positions of the sensor;

high performance, easy operation and maintenance;

diagnostics of the operated equipment with the purpose of an estimation of its residual safe resource;

self-shutdown.

MINETEK CJSC performs maintenance, repairs (including warranty), primary and periodic verification (calibration) of hardness meters ETM-01.

Main technical characteristics

Limits of the permissible error of hardness measurement during verification (calibration) of the hardness meter according to the working standards of hardness units of the 2nd category according to DSTU 3870-99, DSTU 3869-99 and GOST 8.516-2003 (hardness measures of MTB, MTP, MTB type) in all ranges of measurement and The range of solid hardness readings for measurements at each hardness measure is given in the table.

| Scale | Range of measurement, unit of hardness | Limits of tolerable error, hardness unit (percent), when the position is controlled | The range of readings, hardness units | ||

|---|---|---|---|---|---|

| Name | Notation | 0º | 90º; 180º | ||

| Brinell | HB | from 100 to 400 HB | ± 5,0 % ± 7,5 % | ||

| Rockwell | HRC | from 25 to 65 HRC | ± 2,0 HRC ± 2,5 HRC | ||

| Vickers | HV | 450 to 800 HV | ± 4,0 % ± 6,0 % |

Time of one measurement, sec, not more - 5.

The supply voltage of the hardness tester, V - 3.0 (two elements of type A-316).

The hardness meter provides an indication when the supply voltage drops to 2.6 V.

The resource of continuous work on one set of food, hour - 300.

Time of automatic shutdown of the hardness meter after the last measurement, min - 1.5.

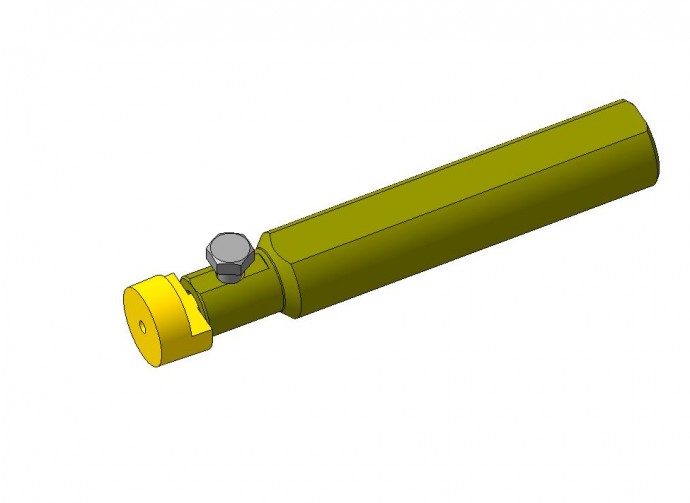

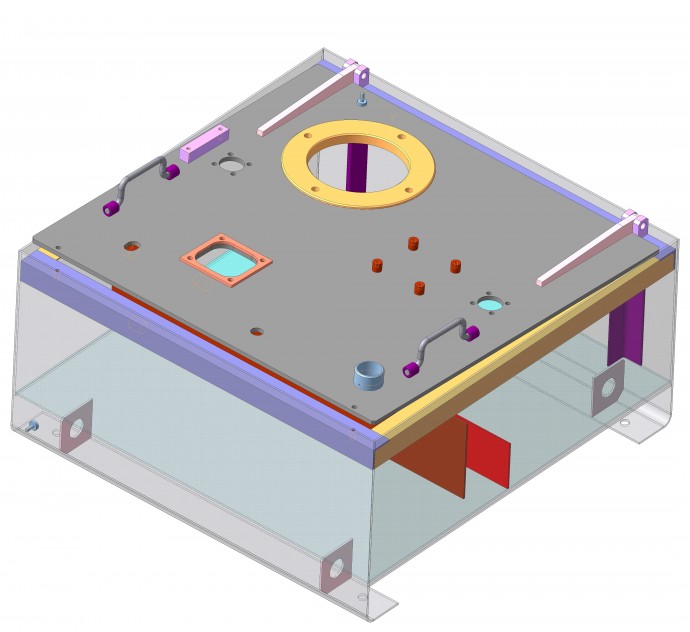

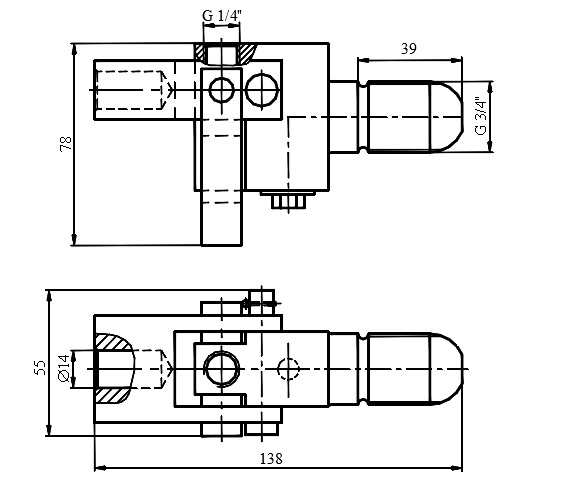

Overall dimensions of the electronic unit, mm, no more - 146х82х40.

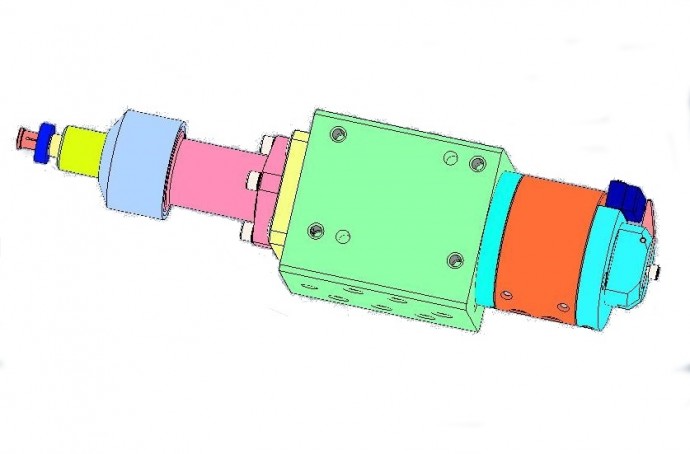

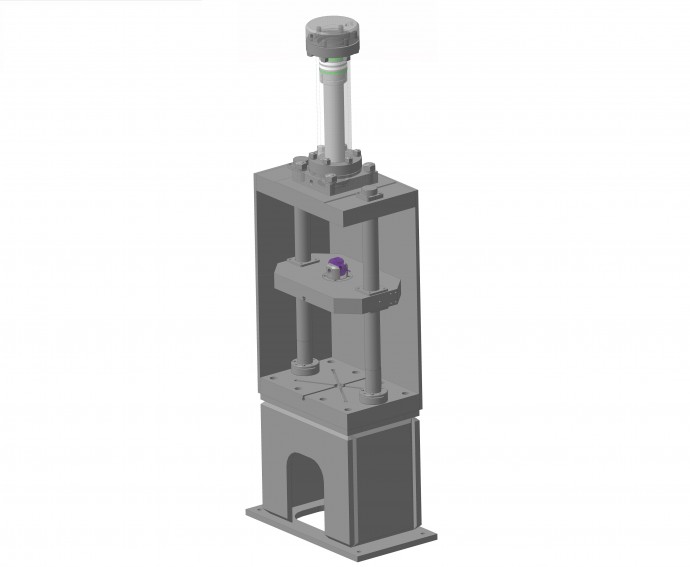

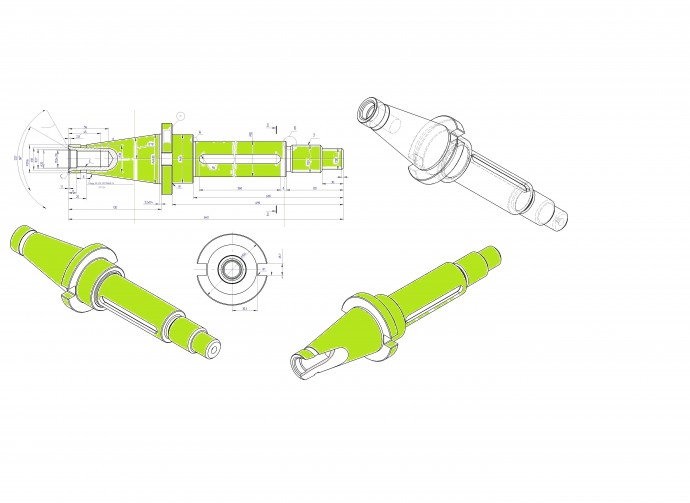

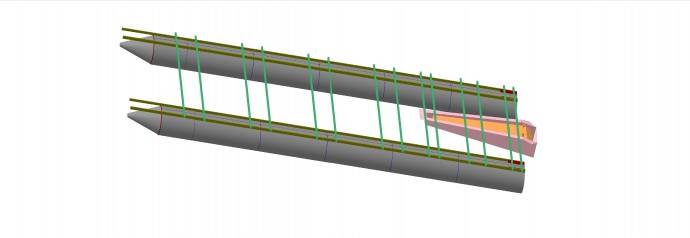

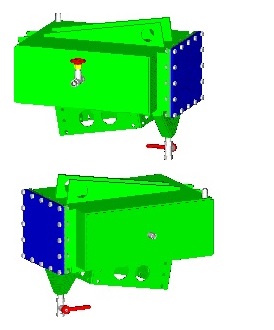

Overall dimensions of the sensor, mm, not more than - Ø 22х110.

Electronic unit weight, kg, no more than 0,25

Sensor weight, kg, not more than - 0.1.

en

en ru

ru uk

uk