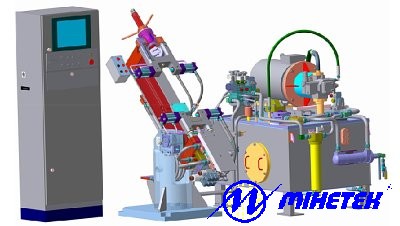

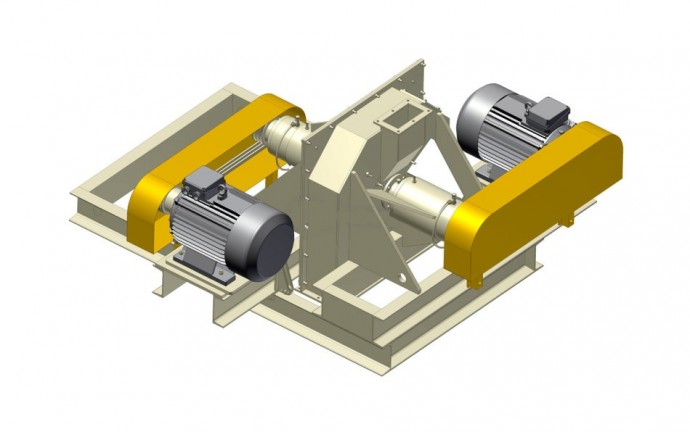

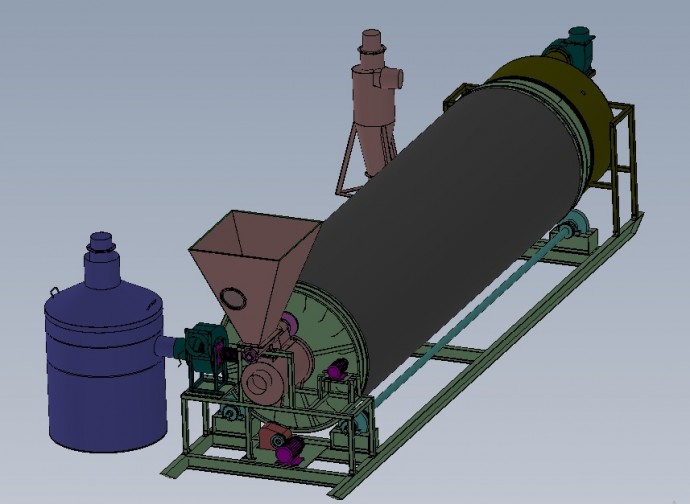

Small size crusher

CENTRIFUGAL CRUSHERS FOR COAL MILLING

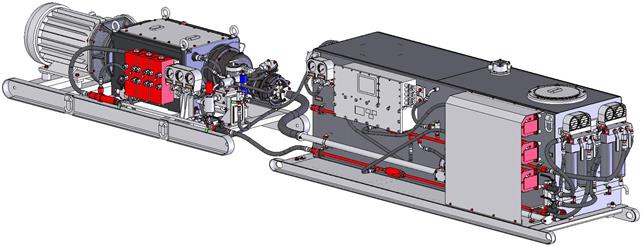

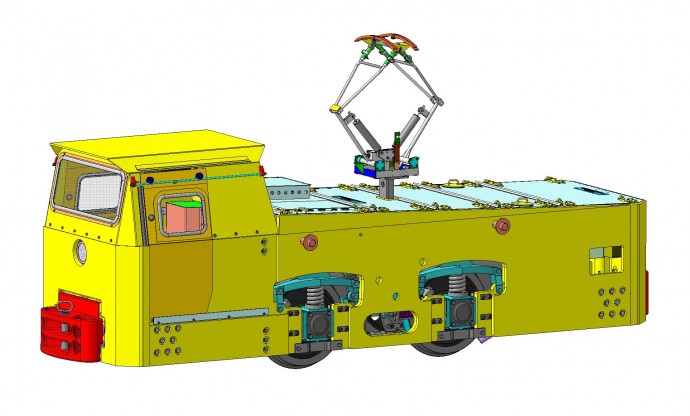

The Crusher (due to its low weight and dimensions it can serve as a universal means of mobile work when preparing coals of the desired fraction in ports, warehouses, etc.).

The crusher is designed for crushing coal crumb with its maximum size of 13 mm to produce a 5 mm grinding product in coal and shale mines, in coal storages, including hazardous gas and dust.

Technical specifications

Diameter of cups, mm ................................................ 300;

Nominal frequency of rotation of cup-shaped disks, min-1 ................ 1500

The largest size of coal fraction to be grinded, mm ............ 13;

The size of the coal fraction after grinding, mm .......................................... .. 5;

Productivity (approximate), m3 / hour ......... ................ 15;

Power consumption, kW ...................................................... ... 15х2

Supply voltage, V ........................................... .................. ... 380;

Frequency Hz ……………………………………………………………………. 50;

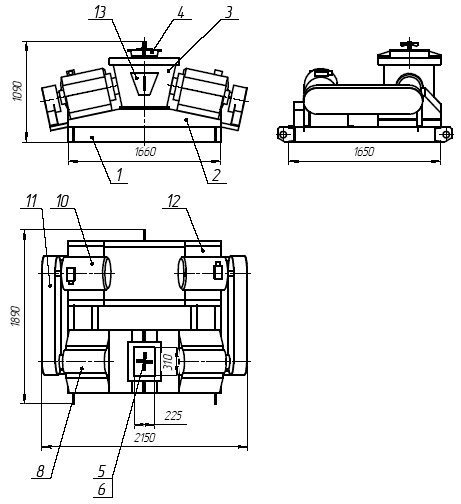

Overall dimensions, mm, not more than

length ............................................................................................. 2150;

width ........................................................................................... 1890;

height .......................................................................................... ... 1090;

Weight, kg, no more than ...................................................................... 2010.

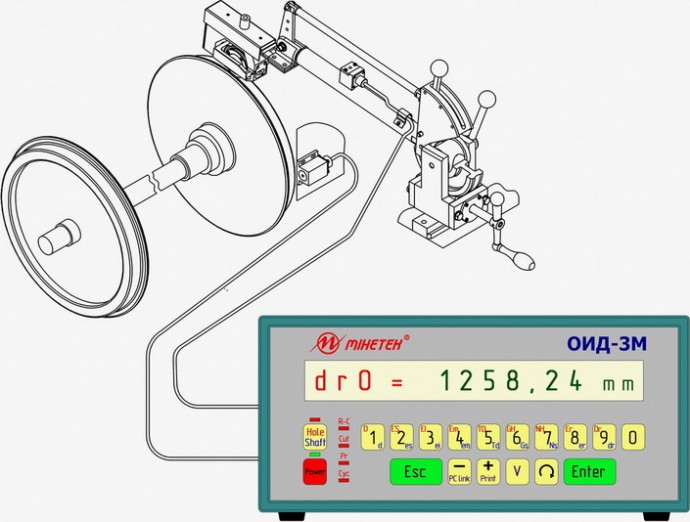

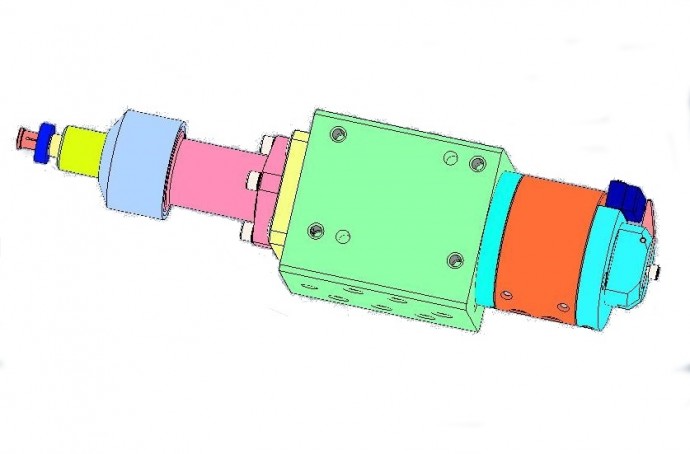

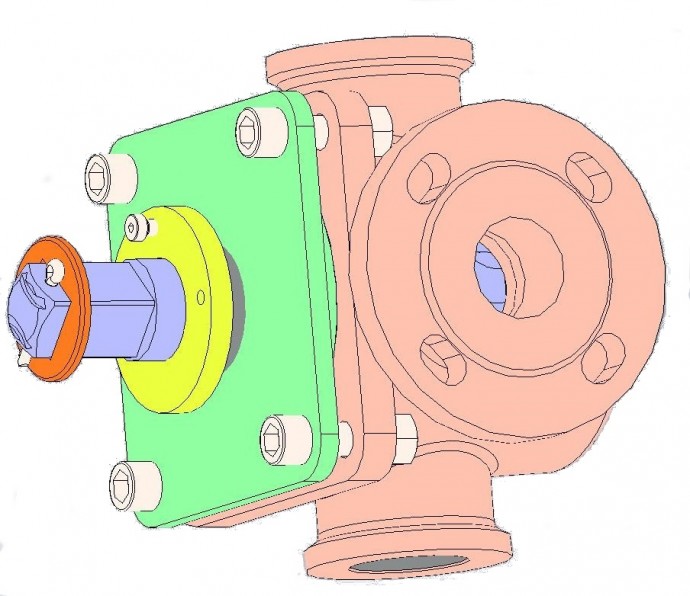

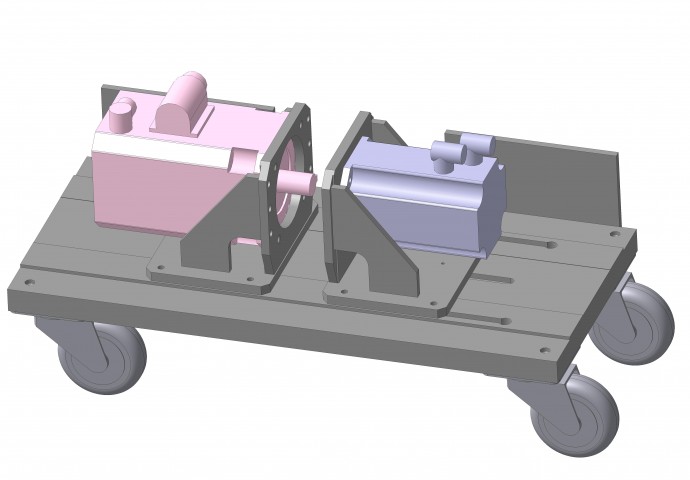

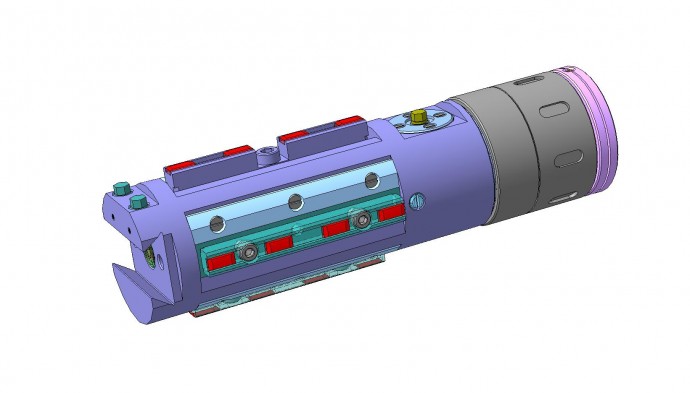

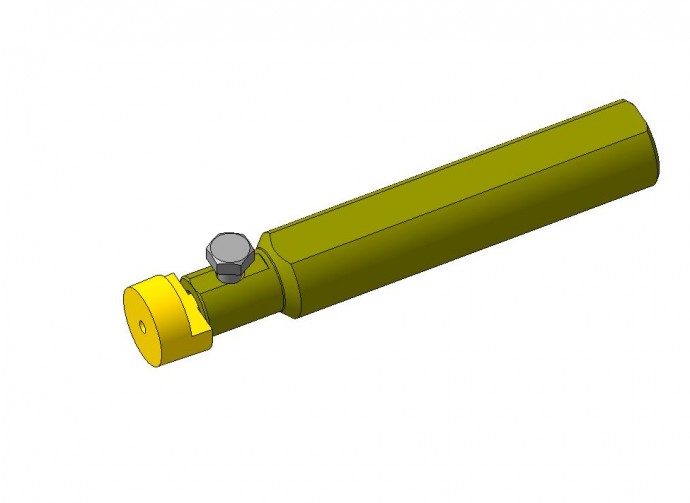

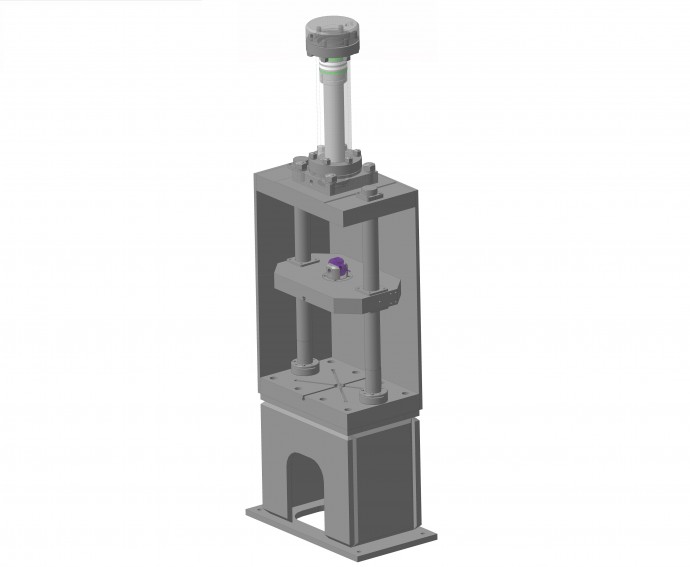

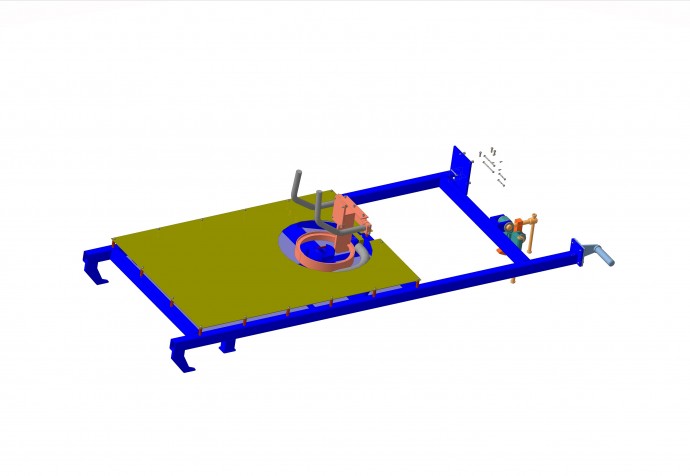

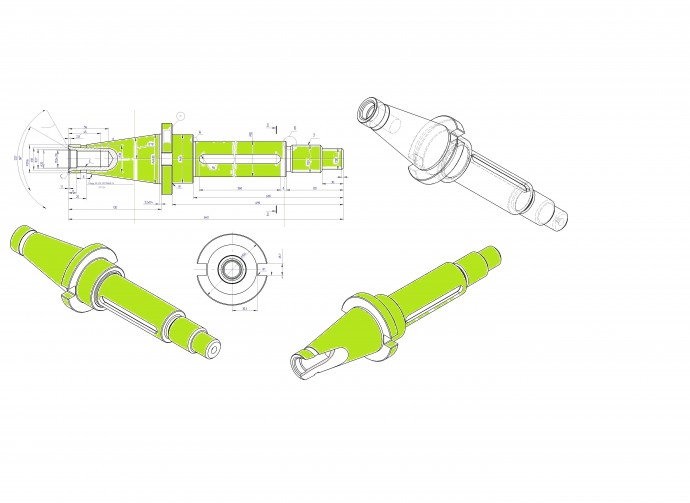

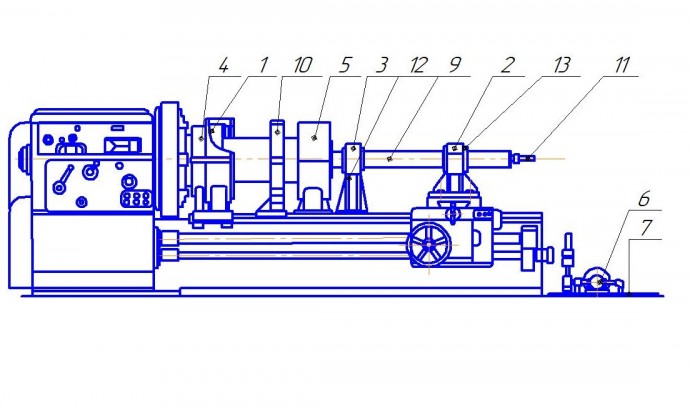

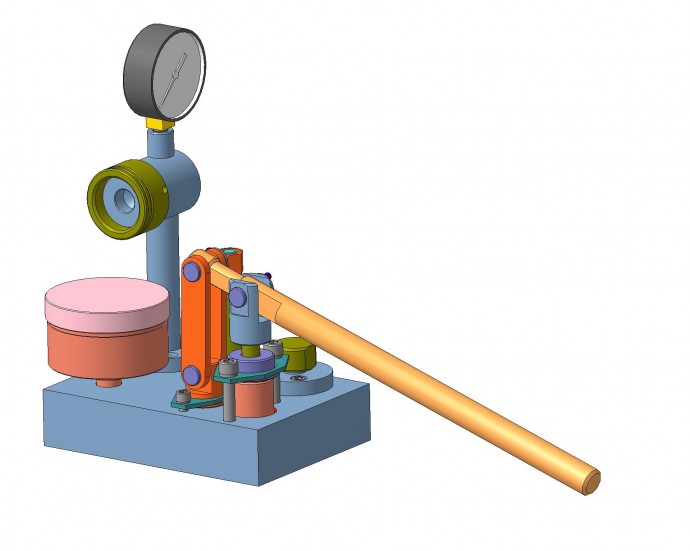

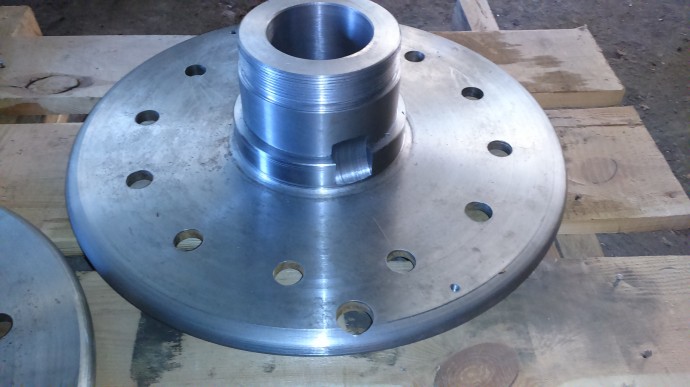

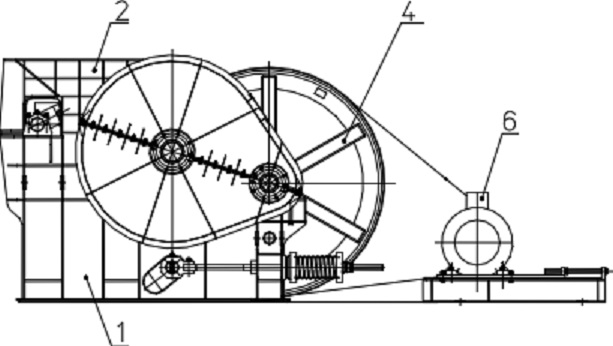

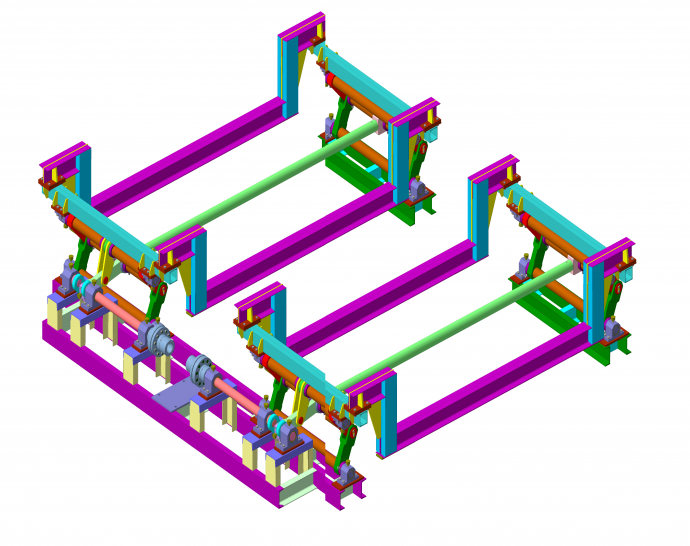

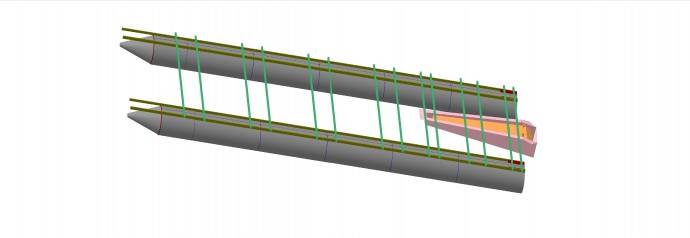

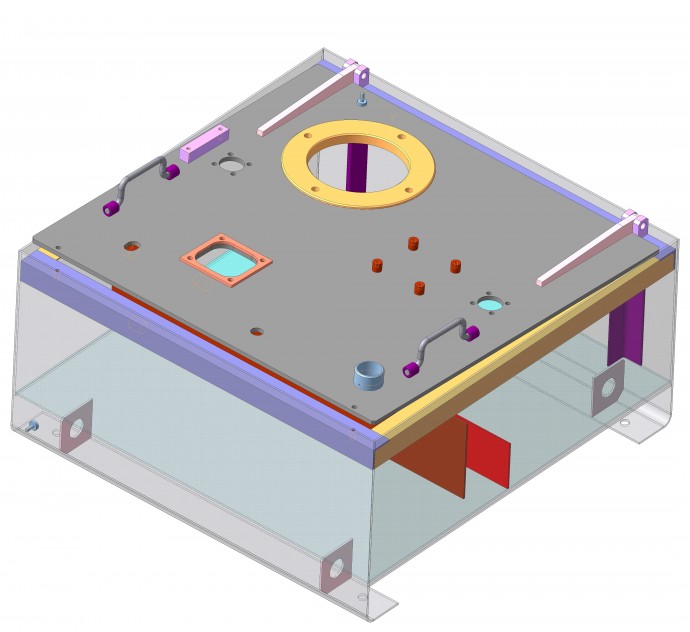

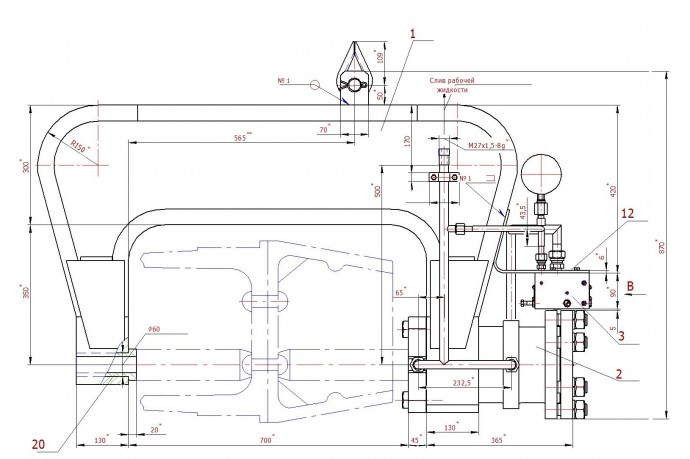

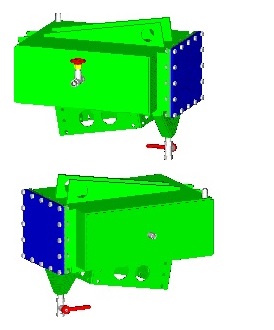

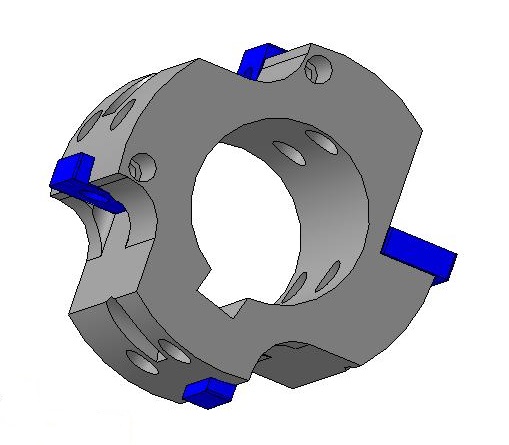

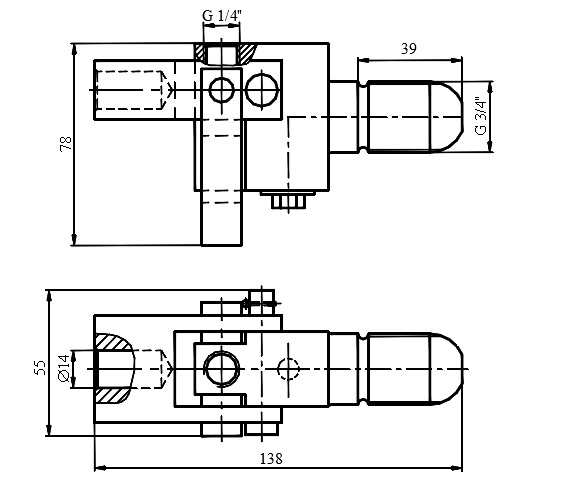

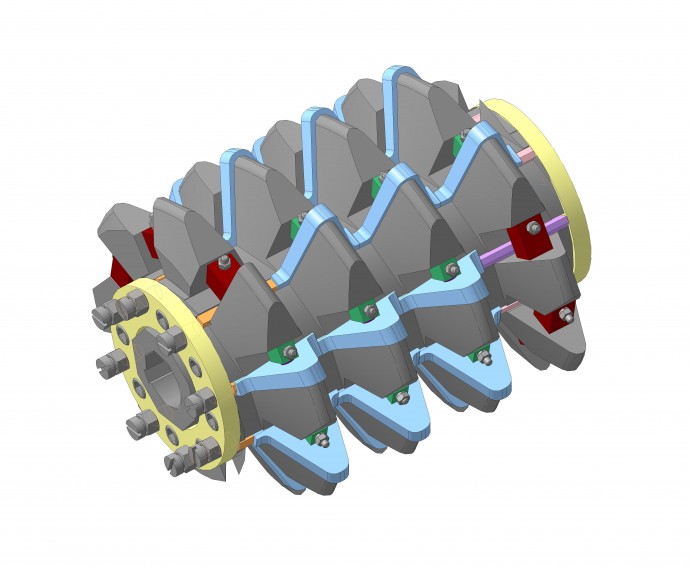

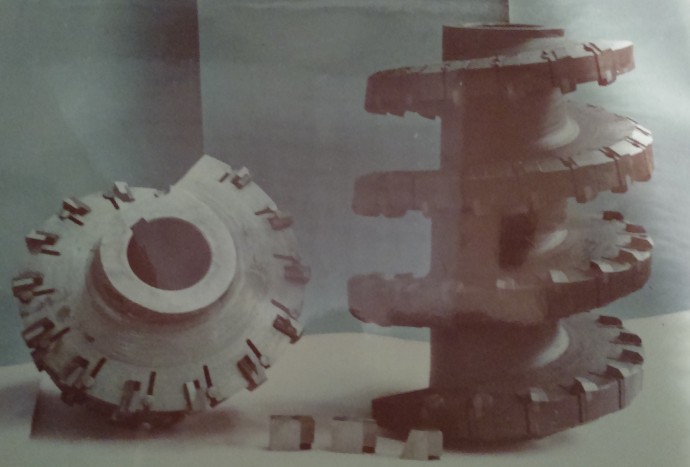

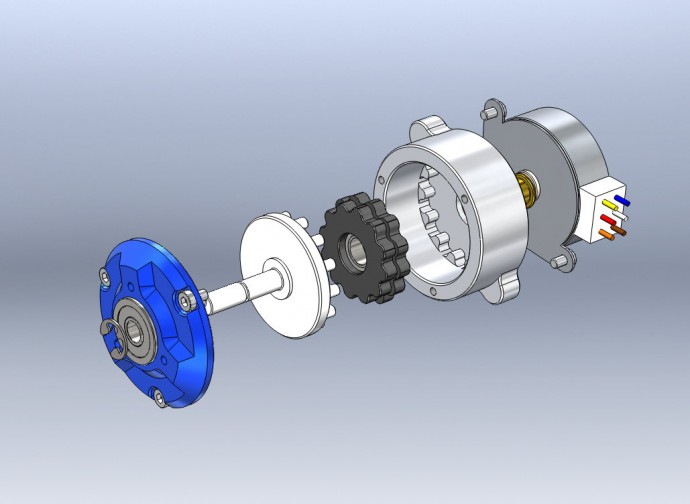

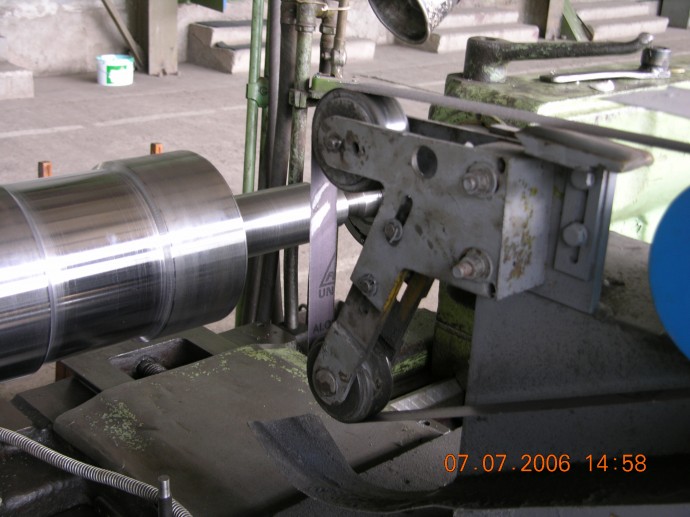

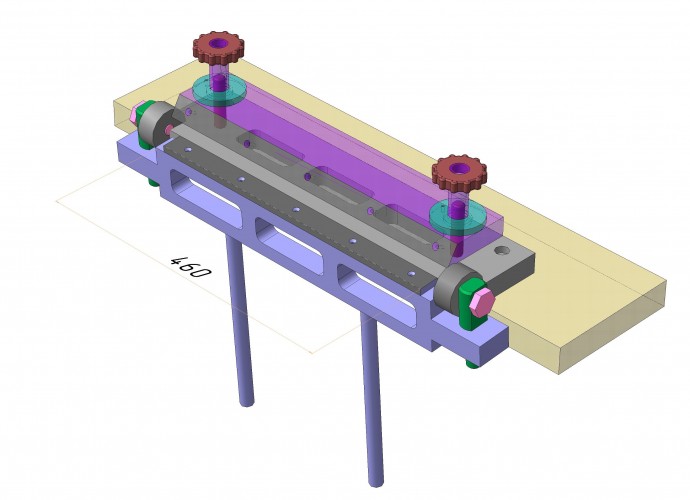

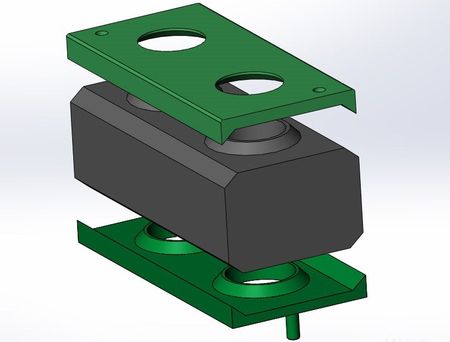

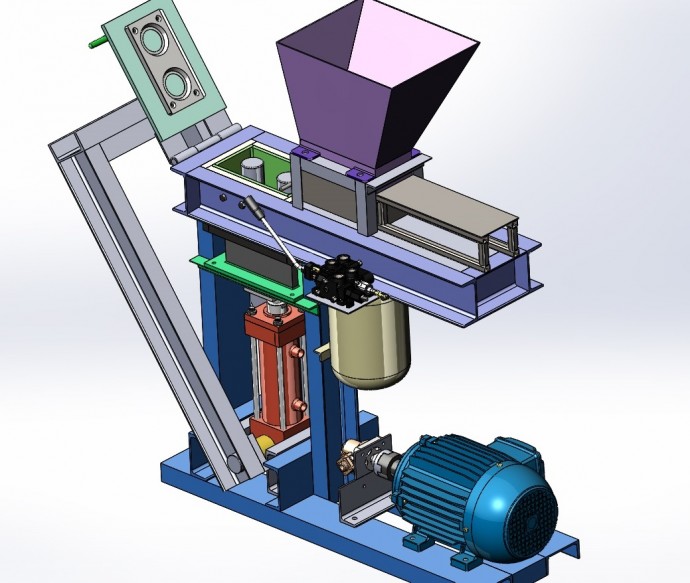

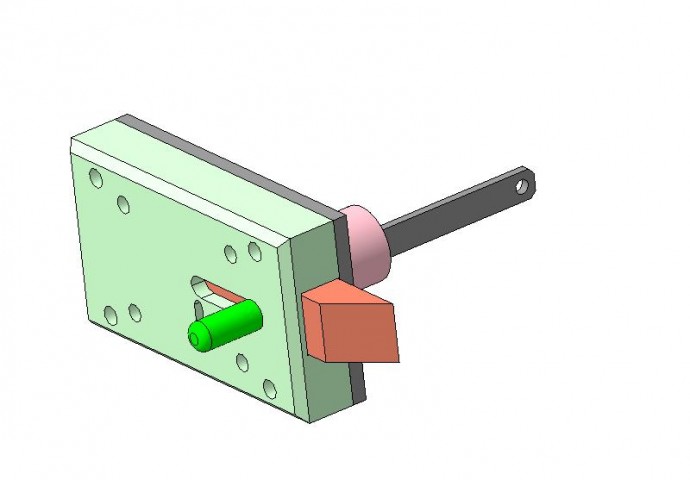

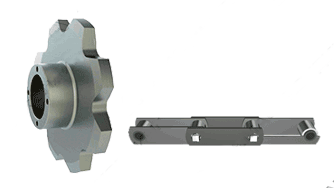

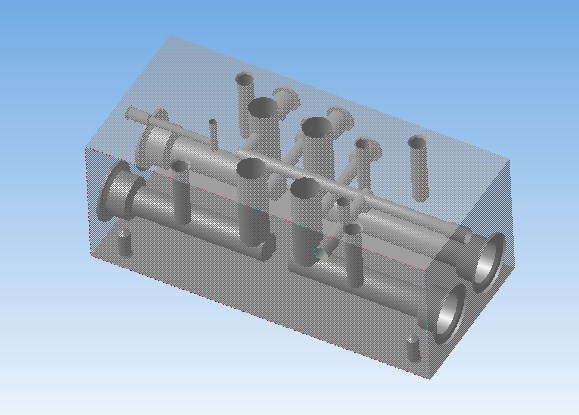

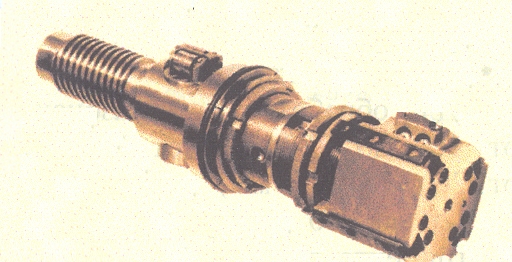

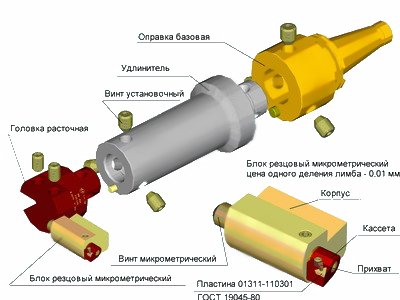

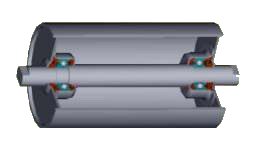

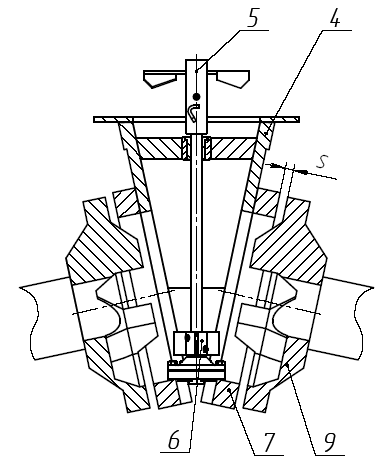

On the frame 1 according to the figure 1 there is installed a bed 2 on which the body 3 is fixed. In the housing 3 there is a grinding chamber 4 (according to figure 2), in the upper part of which there is a charging hole for coal, and in its inner cavity there is a tedder with impellers 5 and 6. On the two inclined walls of the grinding chamber, there are side openings. Flanges 7 are mounted on the same inclined walls of the grinding chamber. On the frame 2, rotors 8 are mounted, on whose shafts the cup-shaped disks 9 are fixed. On the inner cup-shaped surface, the disks have blades that enter the holes of the inclined walls of the grinding chamber. The rotors are designed to transfer rotation to the discs 9, providing centrifugal forces to loadable coal fractions. The ends of the discs 9 abut the ends of the flanges 7 with an annular unloading gap "S", the size of which determines the size of the coal fraction after grinding.

The

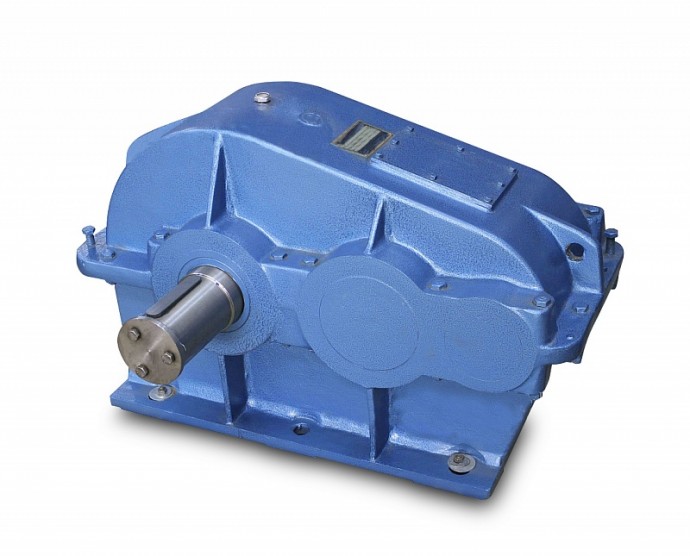

The rotation of the discs 9 is transmitted from the electric motor 10 via a V-belt transmission closed by a guard 11. The motors 10 are located on the pedestals 12 fixed to the frame 1.

The covers 13 are designed to enable the nuts of the flanges 7 to be supported on the inclined walls of the grinding chamber.

en

en ru

ru uk

uk