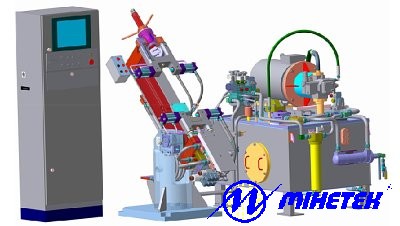

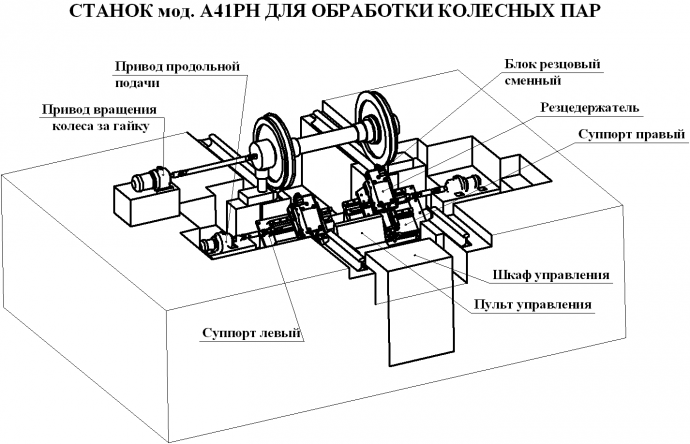

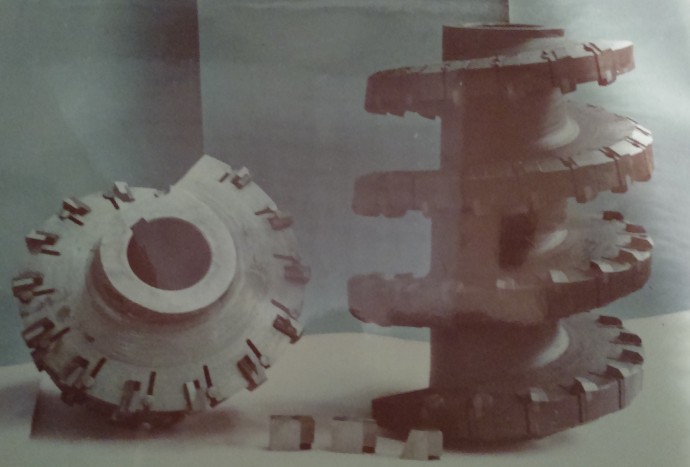

Cutting tool for machining wheel pairs profiles КЖ-1836,А-41,Rafamet

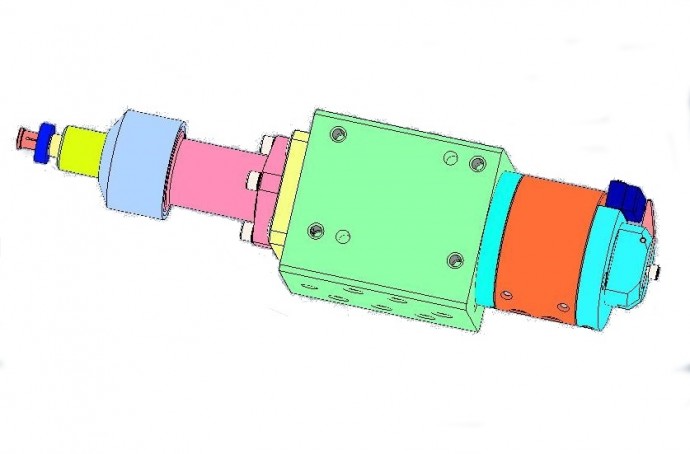

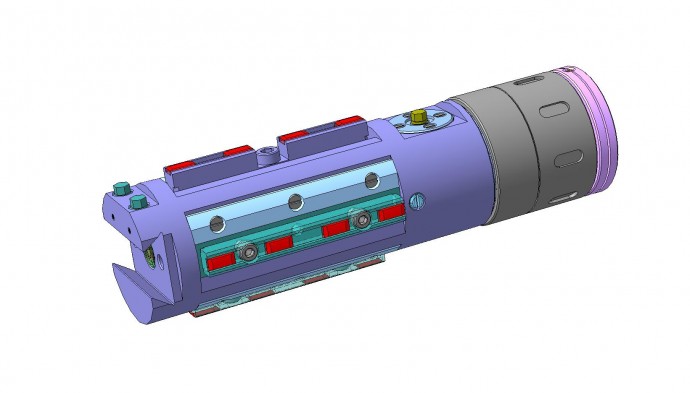

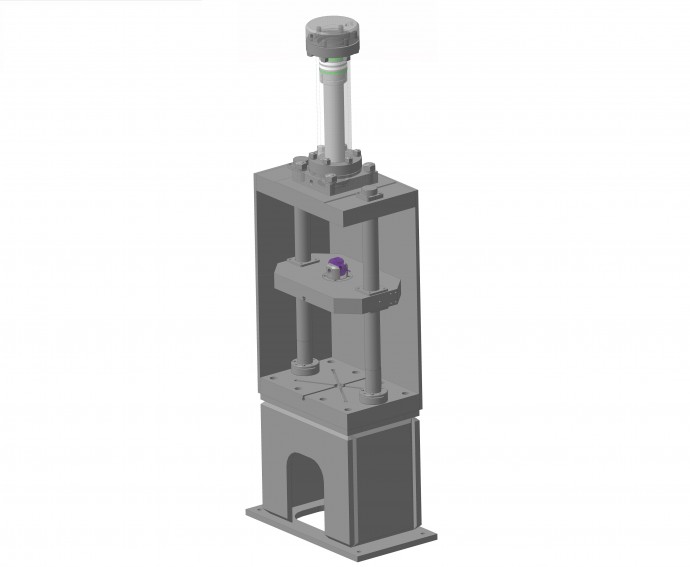

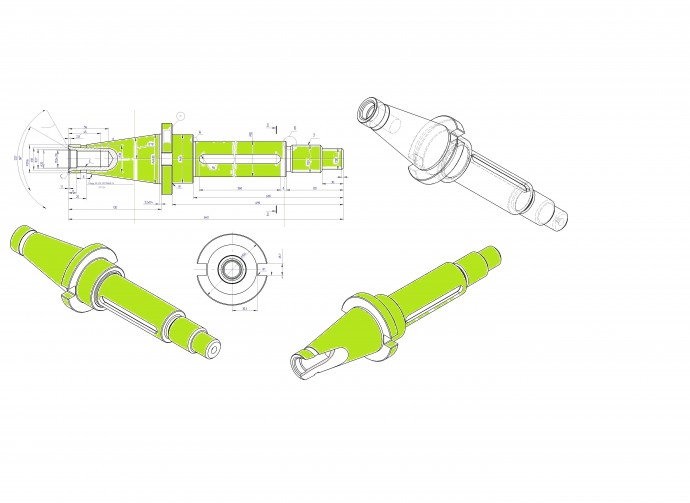

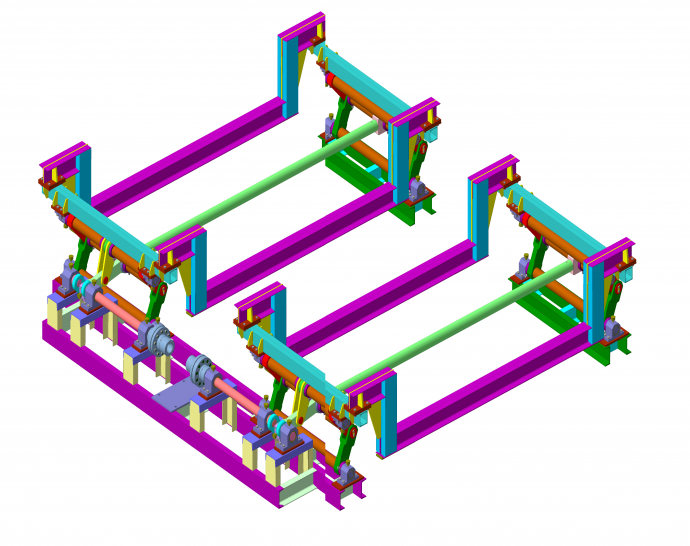

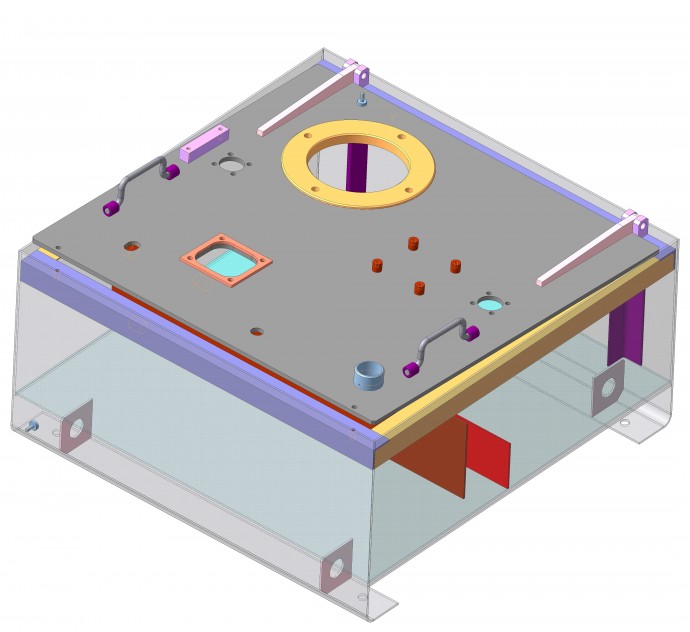

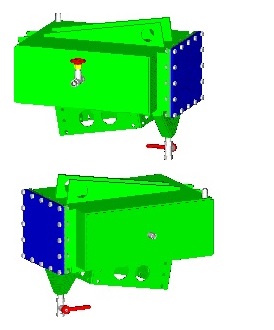

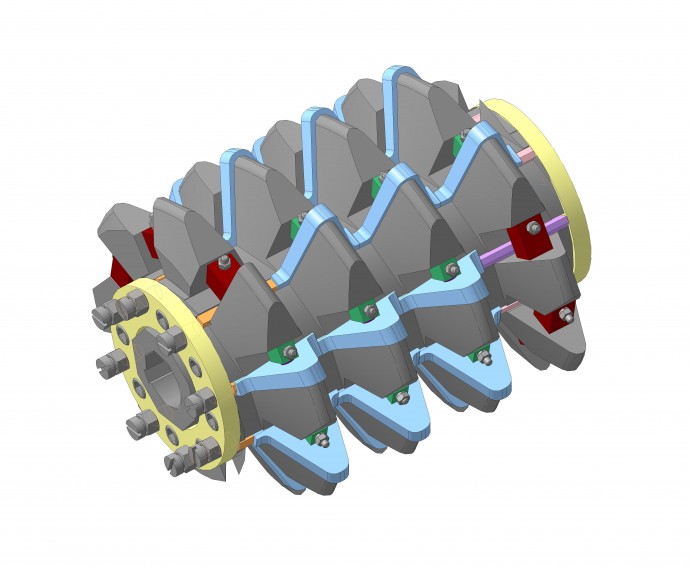

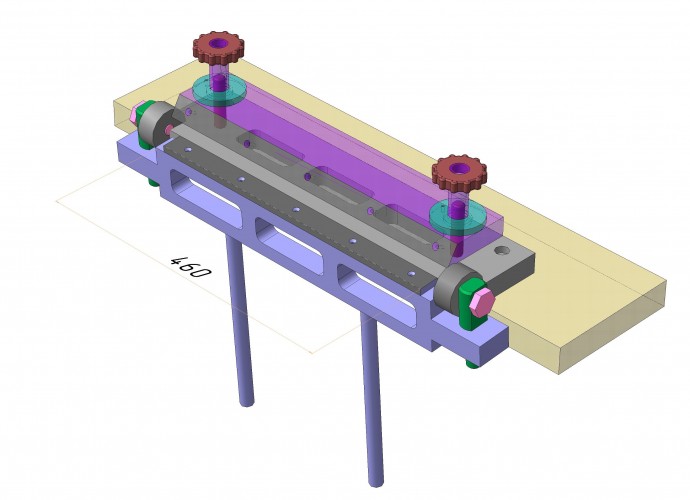

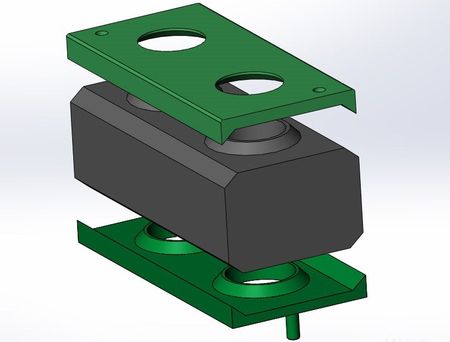

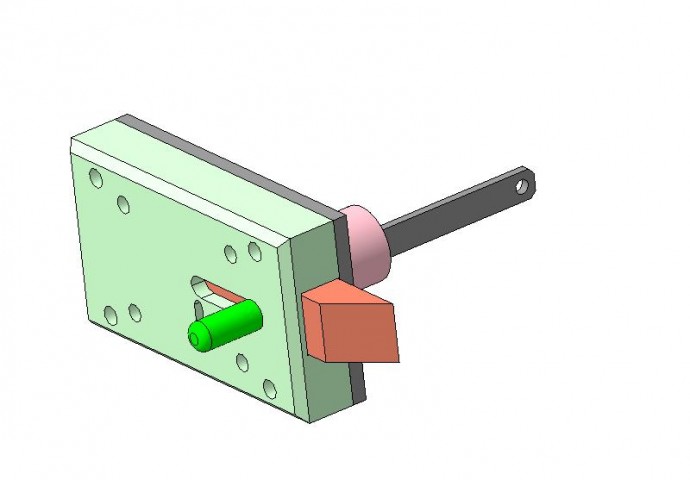

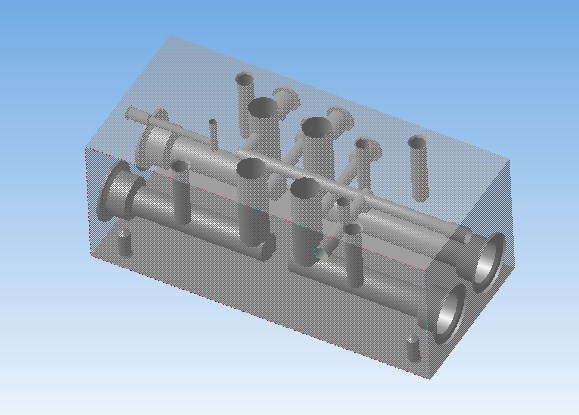

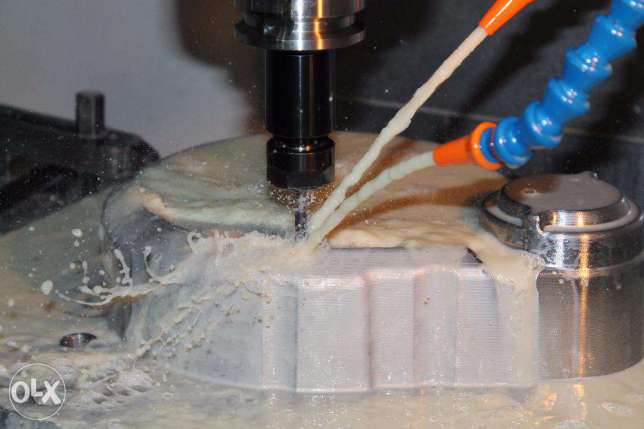

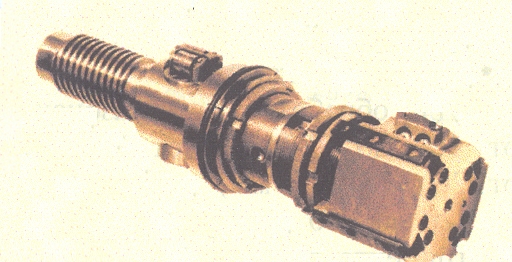

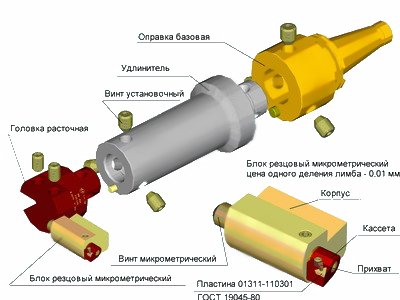

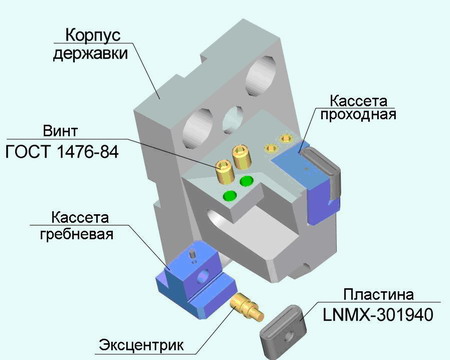

A distinctive feature is the high rigidity and reliability of fastening elements (holder-cassette-plate) in the block system of the tool. Easy maintenance, the ability to safely and quickly replace cassettes with plates. In combination with providing rational cutting angles for heavy machining conditions of wheel pairs profiles with sliders, welds, etc. This allows to increase the hardness of carbide plates of leading European manufacturers (Sandvik, Widia) by 20-25%, and with the appropriate grinding of the geometry of the cutting part of carbide plates of Russian manufacturers, the trademark ZS (certificate No. 39975) and the patents of CJSC MINETEK No. 72835UA, № 74176UА in 1,5-1,8 times.

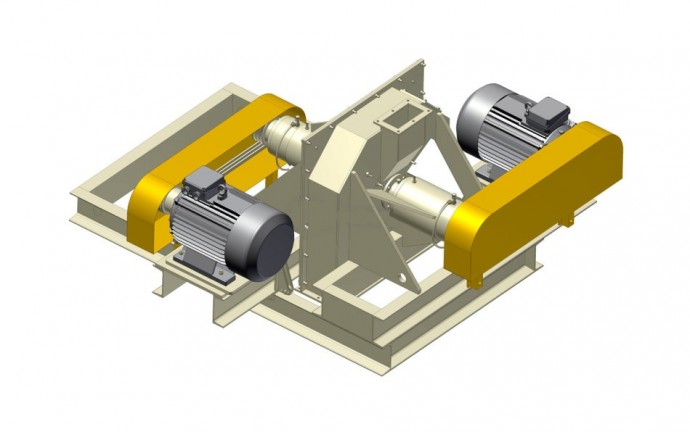

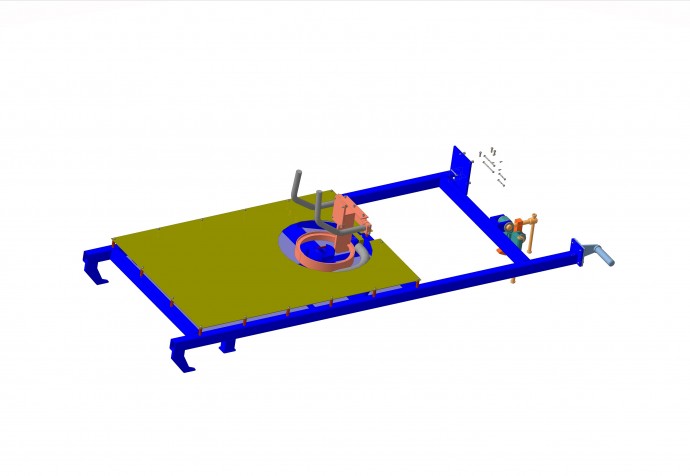

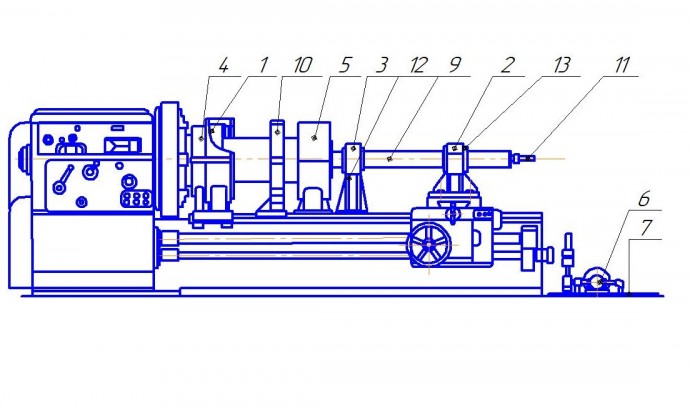

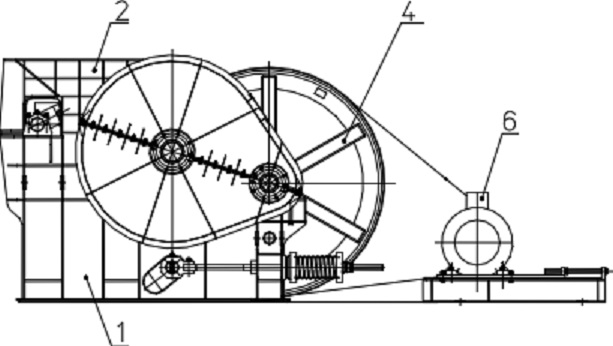

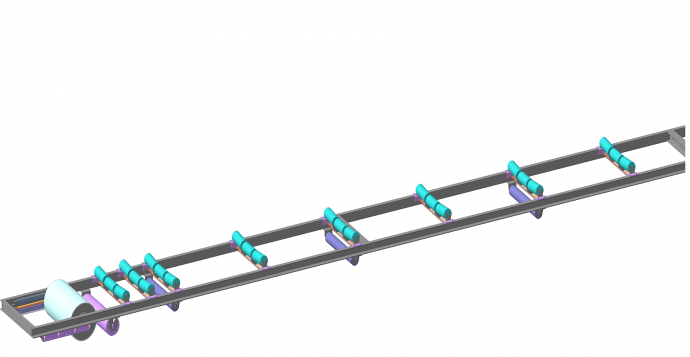

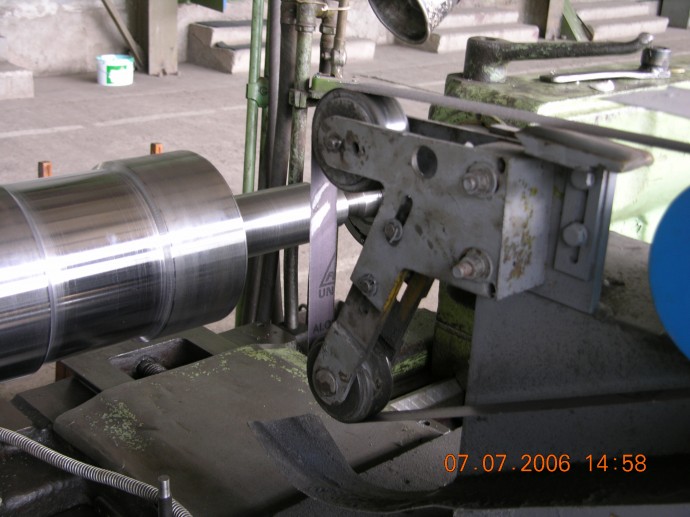

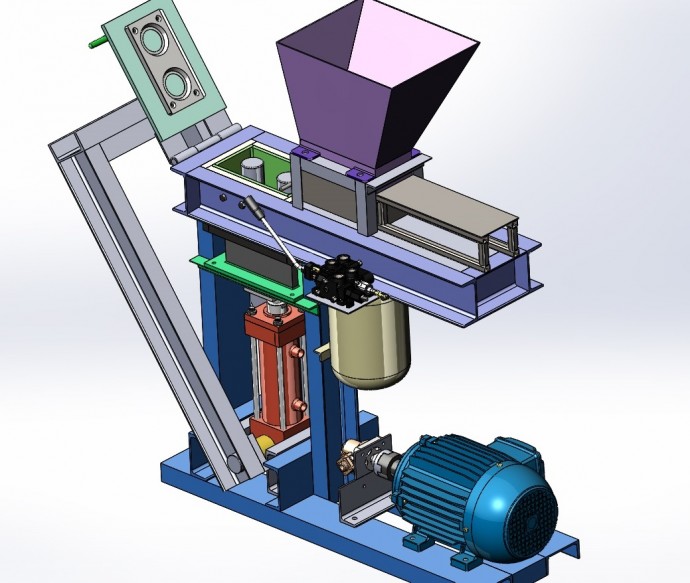

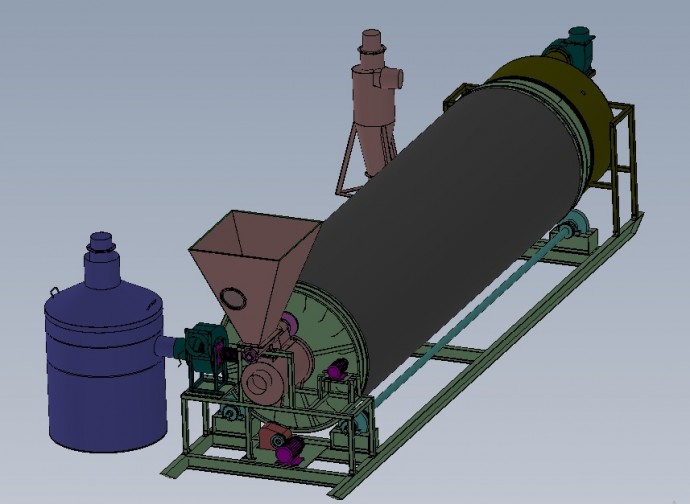

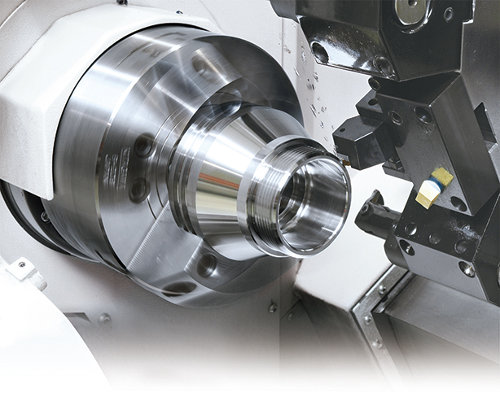

A set of cutting tools can be used on RAFAMET UBC-125, UBC-150 and UGB 150 machines, as well as KZTS. The main customers of the tool are repair enterprises of railways and enterprises that have attached rolling stock.

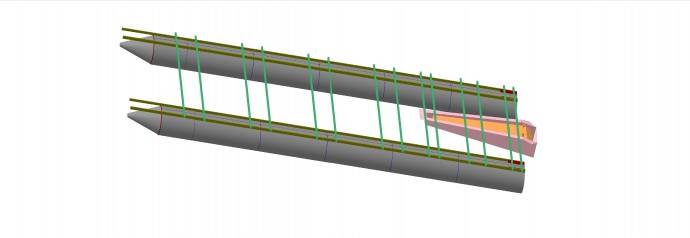

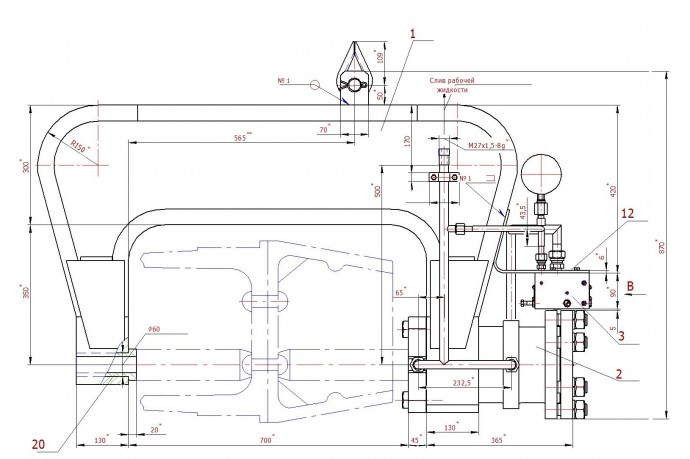

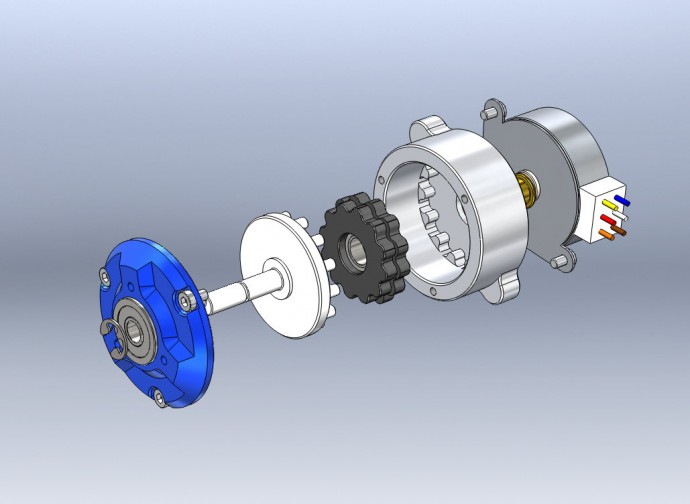

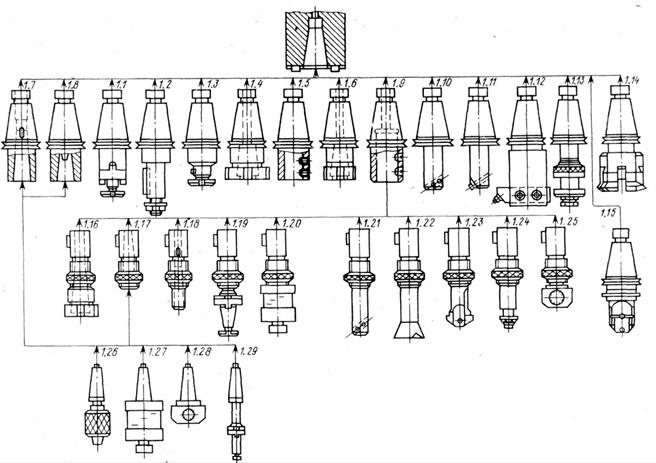

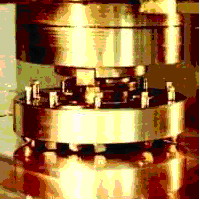

Incisors and incisors are equipped with one or two incisors. The number of incisal inserts and their position in the incisors and incisal blocks provides a normalized roughness of the profile surface of the rim of the wheel pair and the maximum processing capacity.

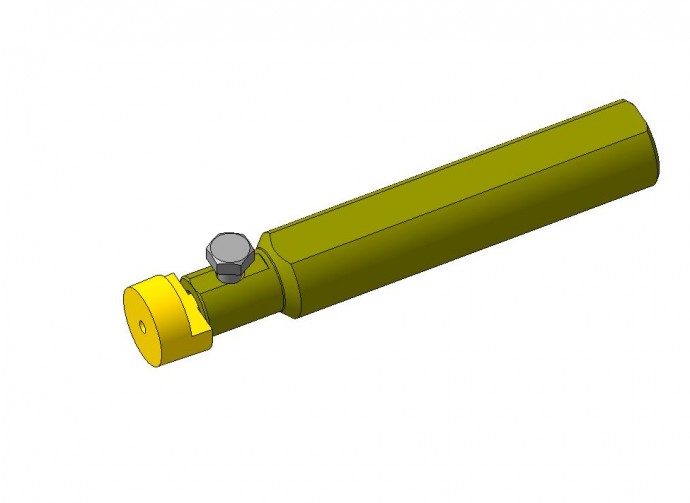

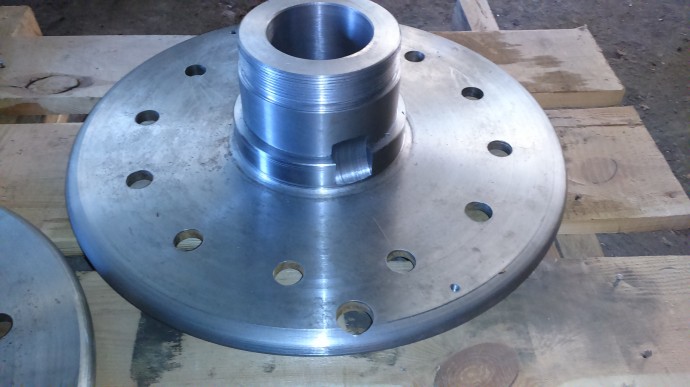

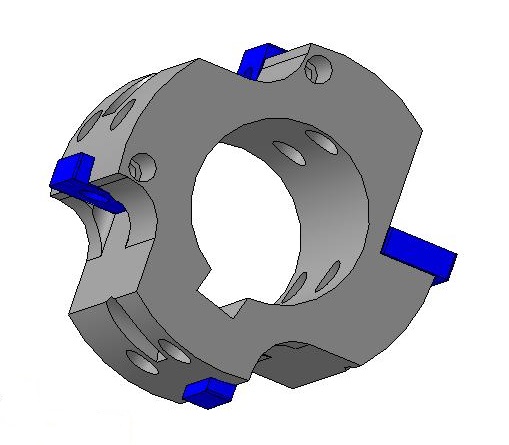

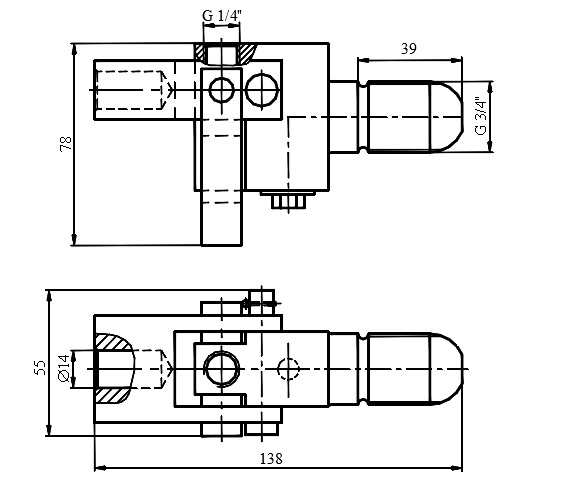

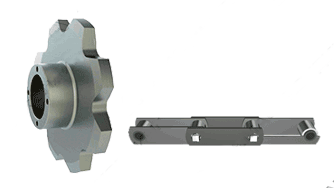

As cutter inserts are used cassettes for plates LNUX 191940, LNMX 301940 and mandrels for plates RPUX 2710MO, RPUX 3010MO.

In the direction of cutting on the machine tool is made in the form of right and left execution.

The left and right instruments are mirror-symmetrical with respect to each other.

Cassettes and mandrels, depending on the version, are equipped with the appropriate interchangeable multi-sided carbide plates, the brand of hard alloy and the dimensions of which correspond to TU U 60.1-23113534.007.

Materials and purchased products that are used for the manufacture of tools meet the requirements of the relevant standards and technical conditions. The quality of the materials used to make the tool is confirmed by quality certificates of the supplier enterprises or laboratory analyzes.

en

en ru

ru uk

uk