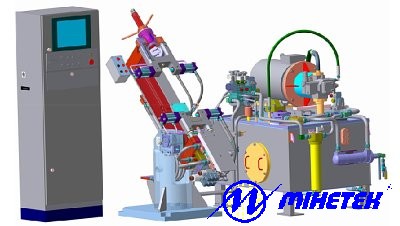

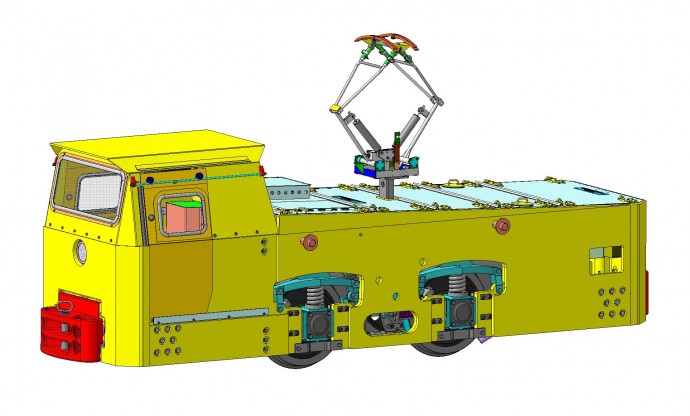

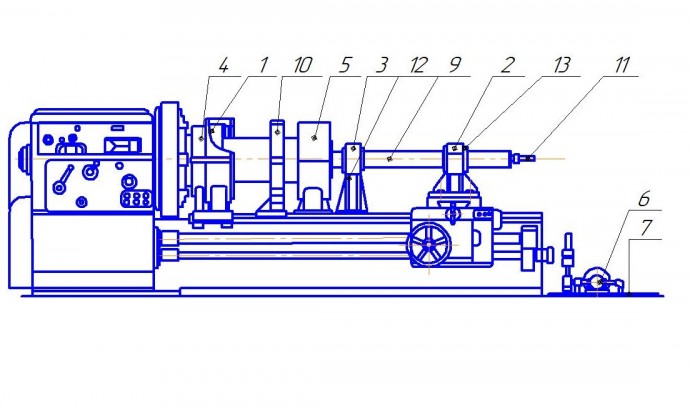

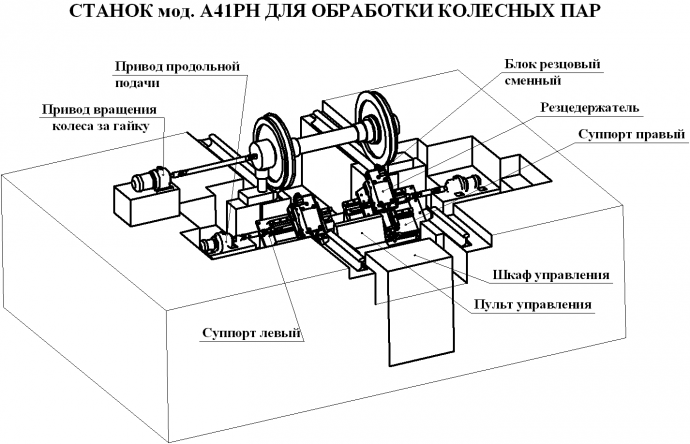

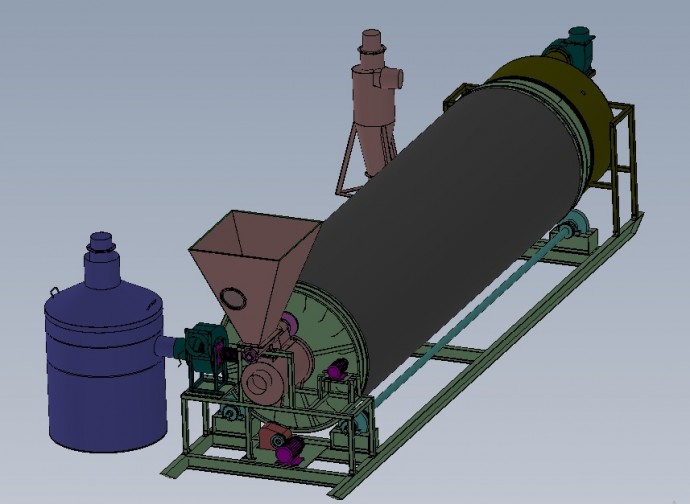

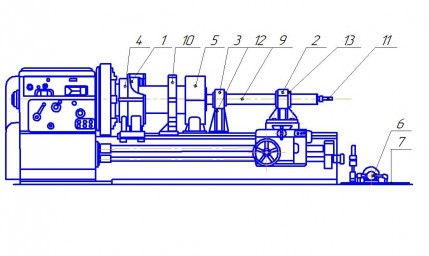

Adaptation and rigging to the turning and cutting machine of model 165 for machining deep holes of pneumo and hydro cylinders, as well as any lengthy bodies of revolution

Fitting and tooling for a Model 165 turning-cutting machine for machining deep holes of pneumo and hydro cylinders, as well as any lengthy bodies of revolution

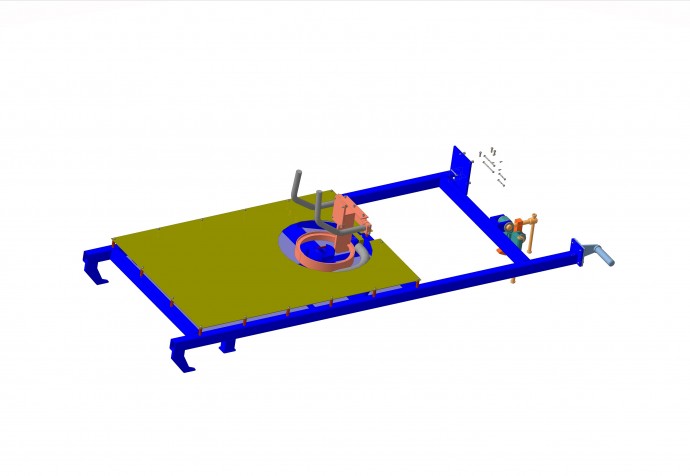

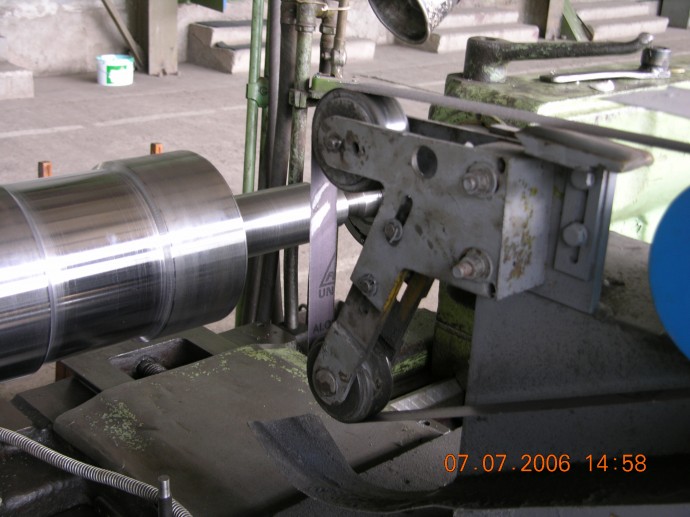

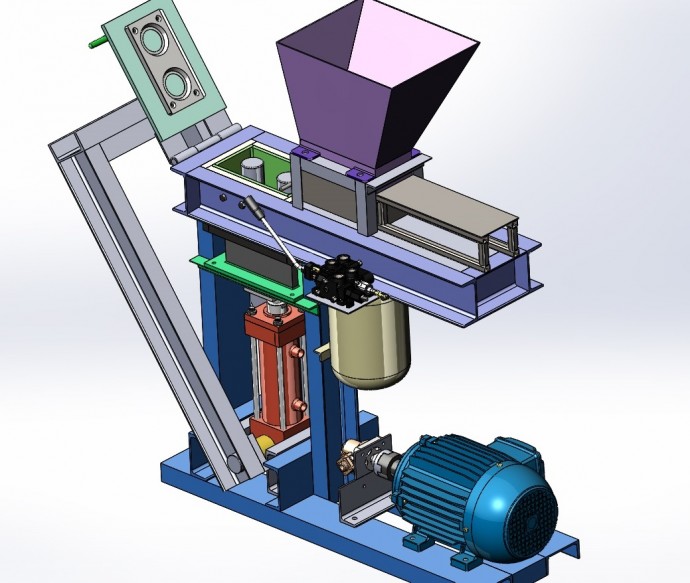

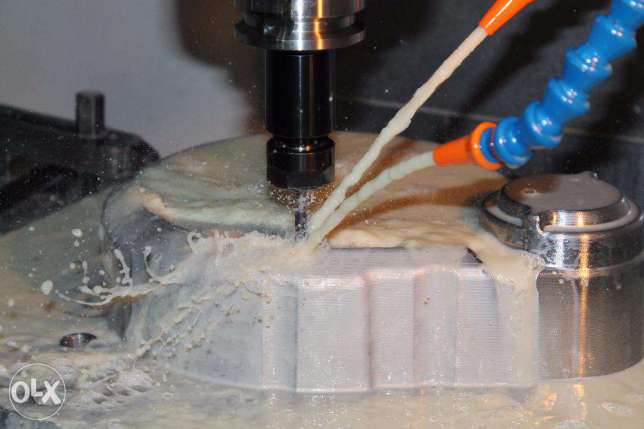

Modernization of the machine is made in order to expand the technological capabilities of the machine and use it when bore holes of pneumatic and hydro cylinders. Modernization allowed to significantly expand the technological capabilities of the machine when processing deep holes of hydraulic and pneumatic cylinders and to obtain the economic effect while refusing to purchase a high-depth machine.

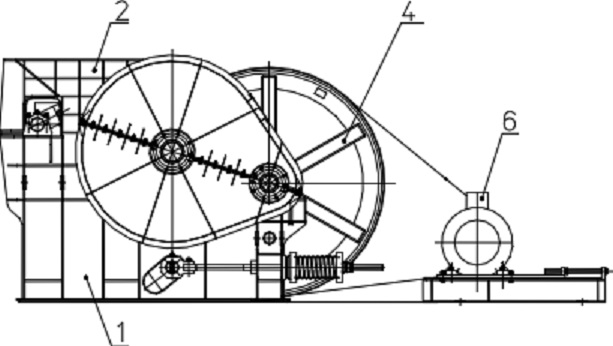

For this, the following auxiliary units and parts were designed:

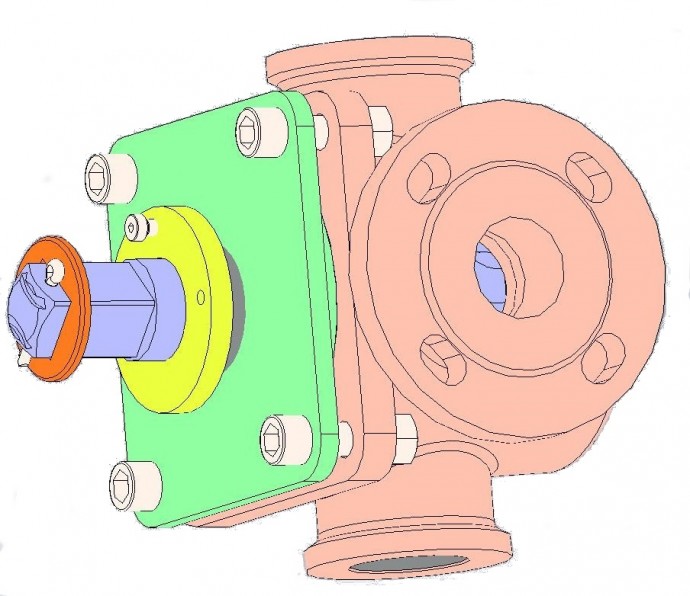

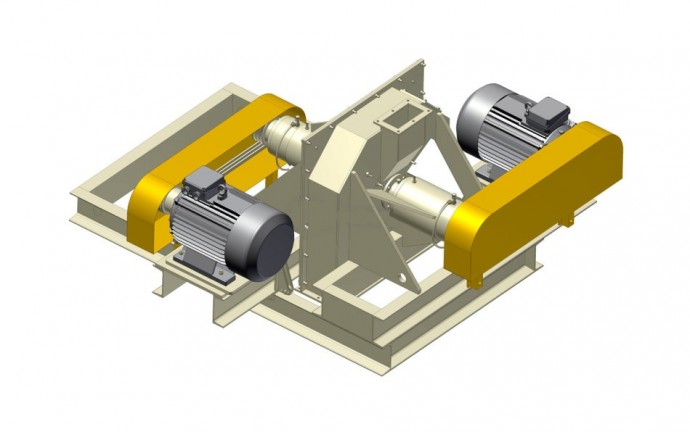

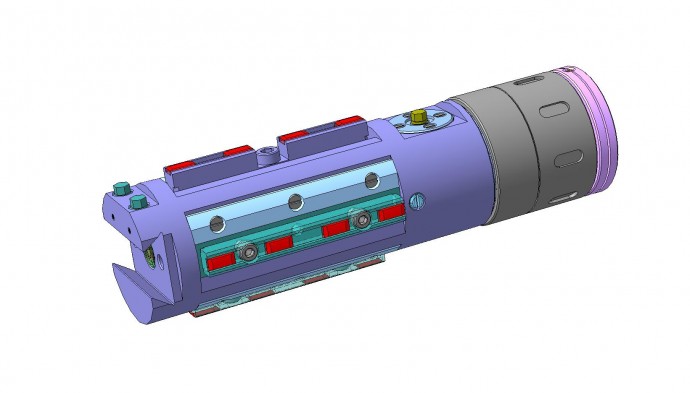

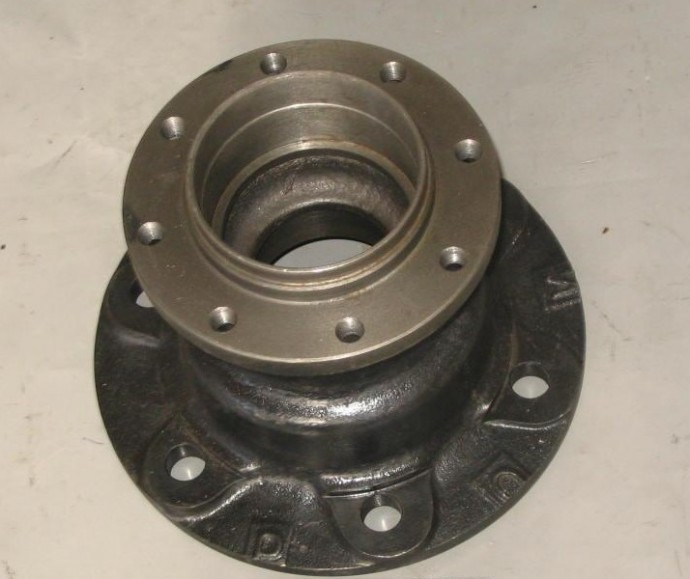

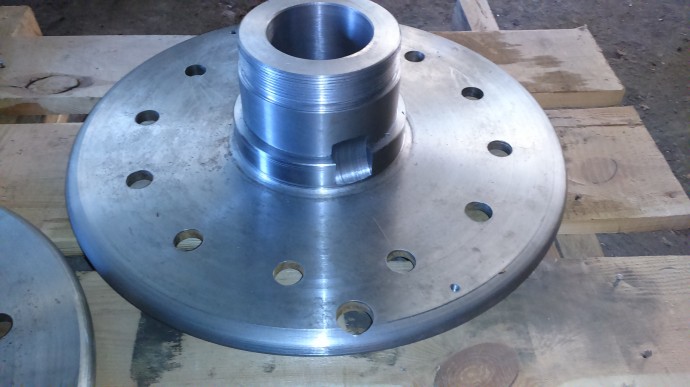

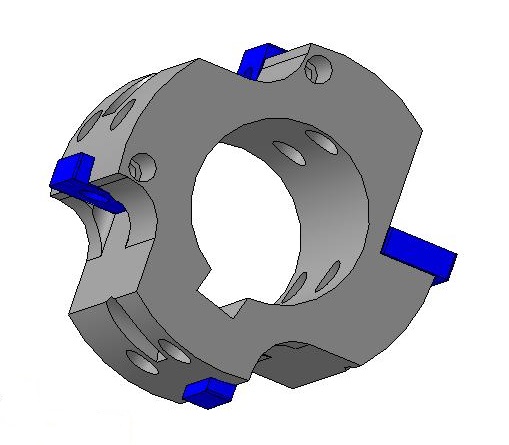

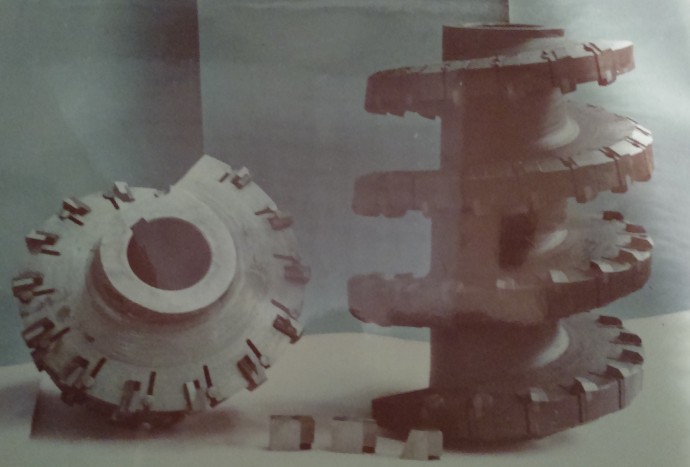

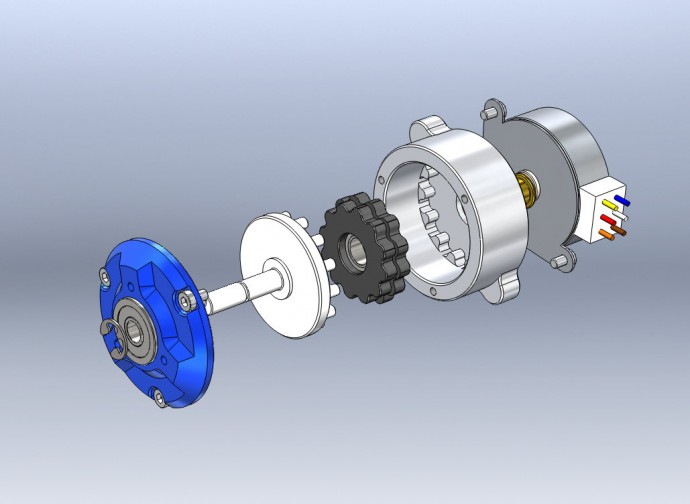

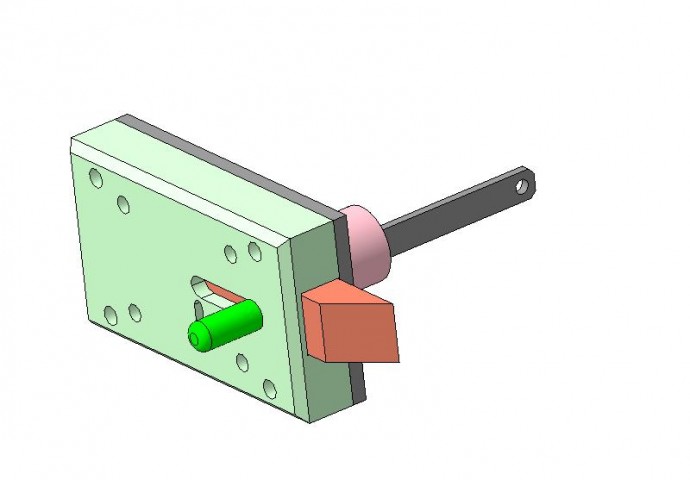

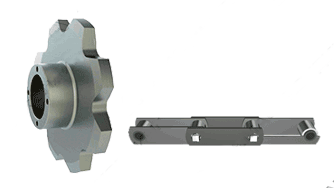

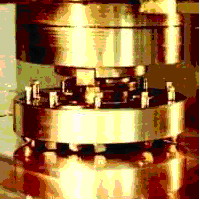

1 - special cartridge

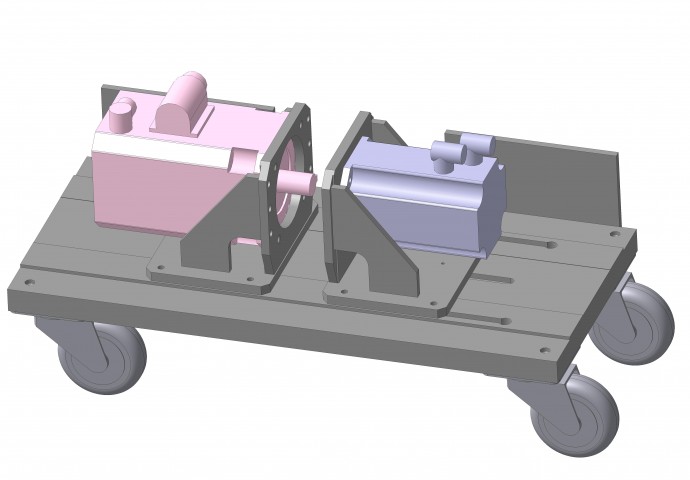

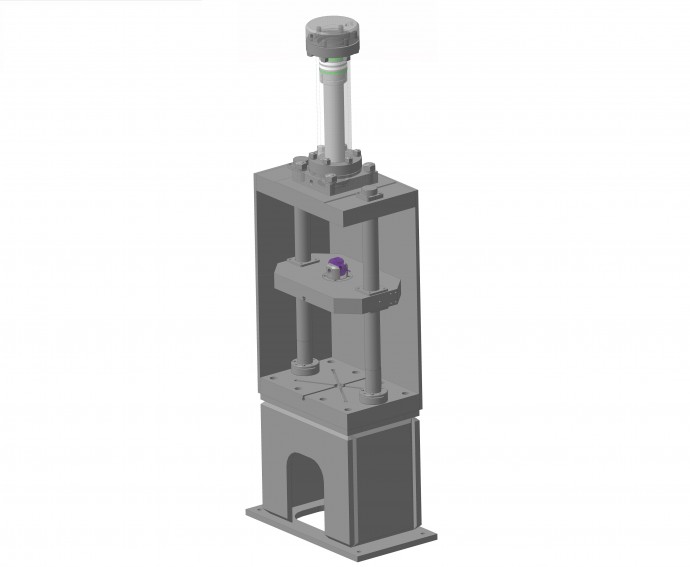

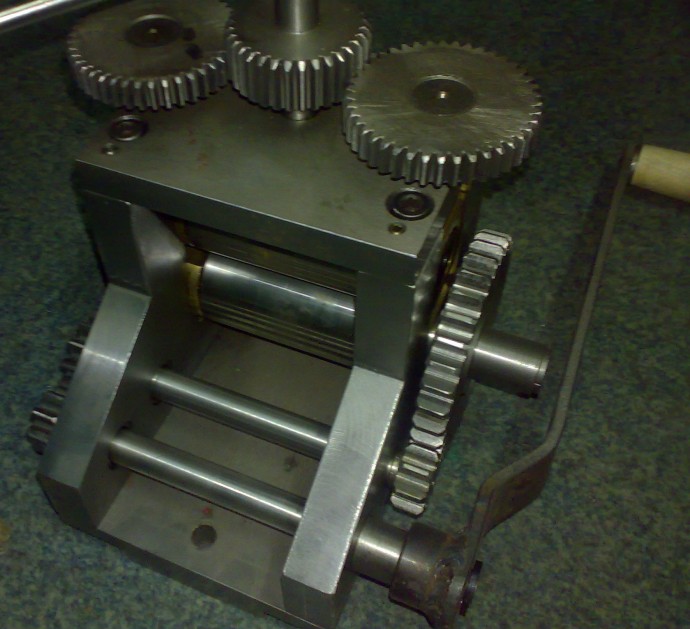

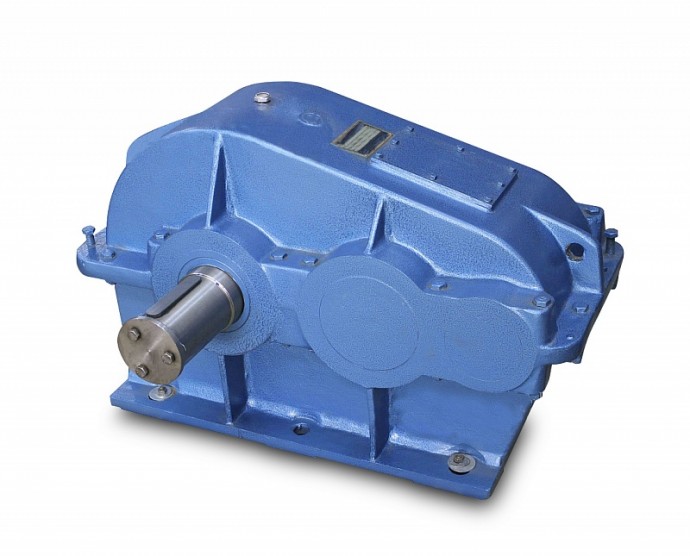

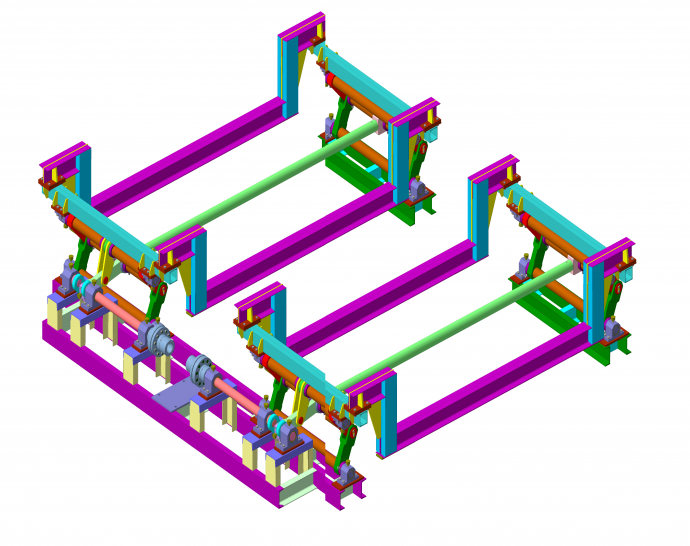

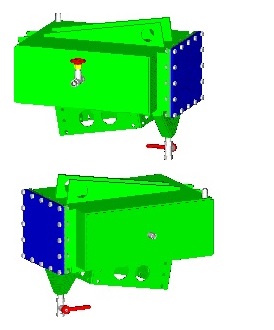

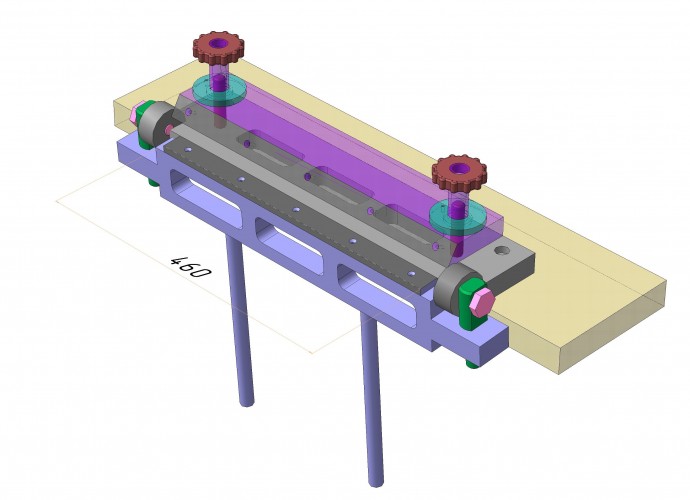

2 - mobile rack

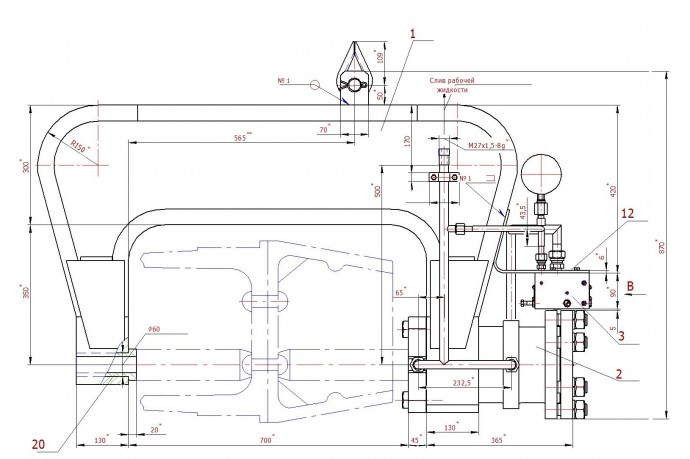

3 -rack support

4,5 - protective covers

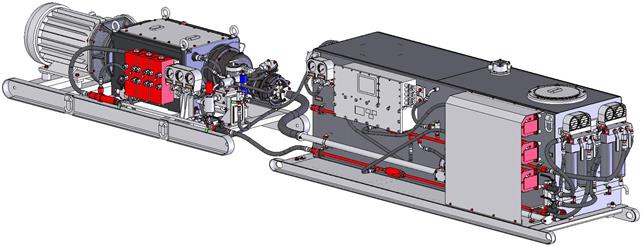

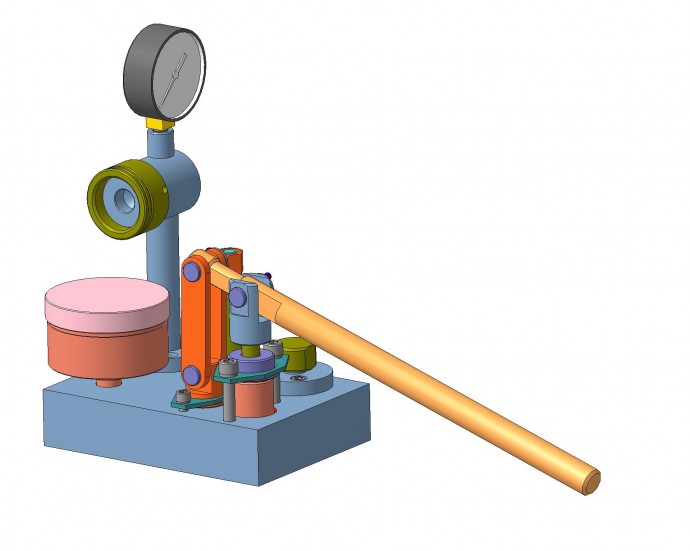

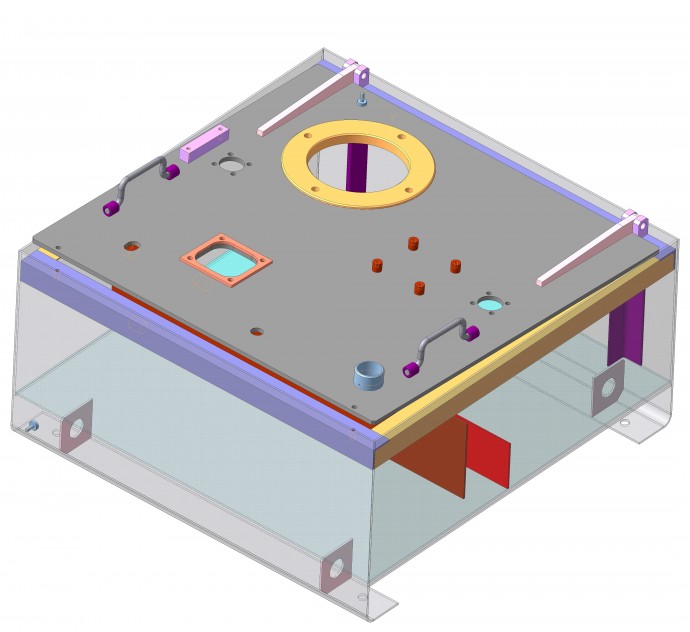

6 -pump station

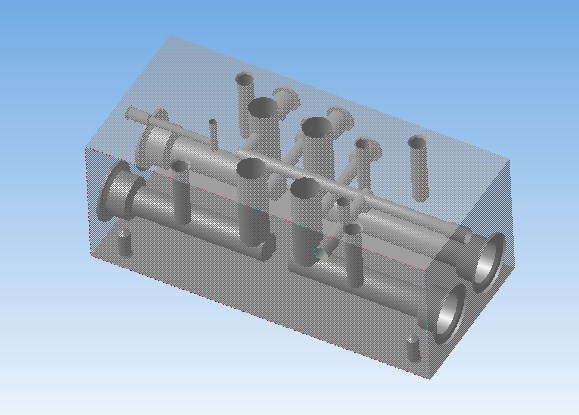

7 - receiving tank

8 - reception trough

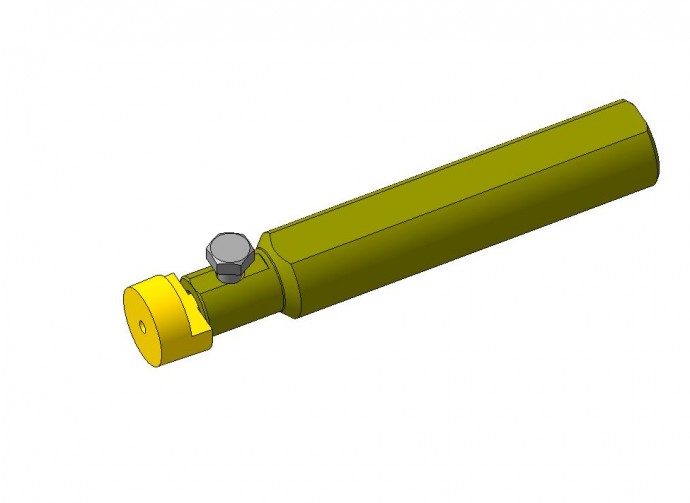

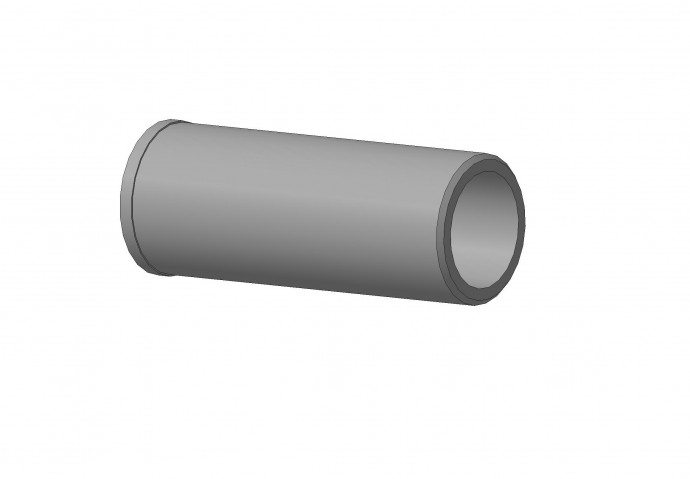

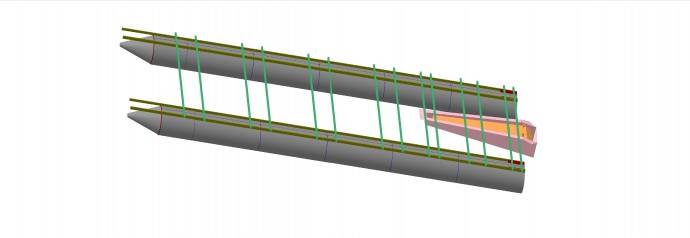

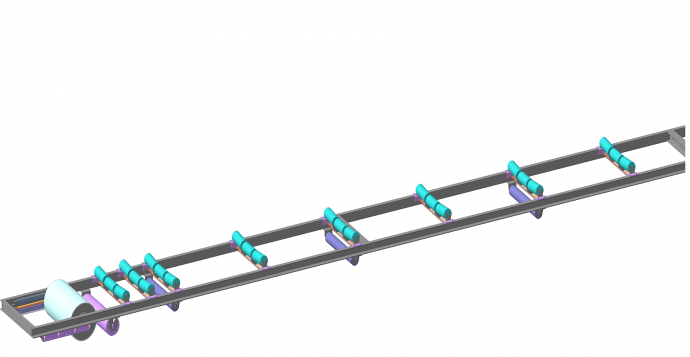

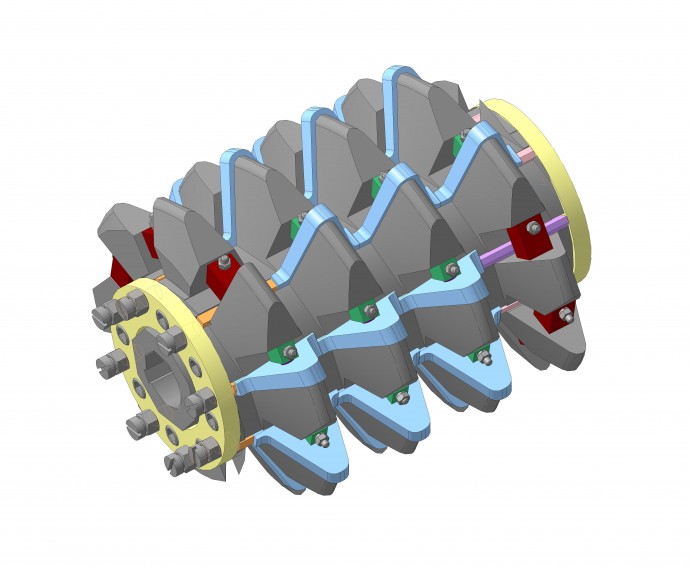

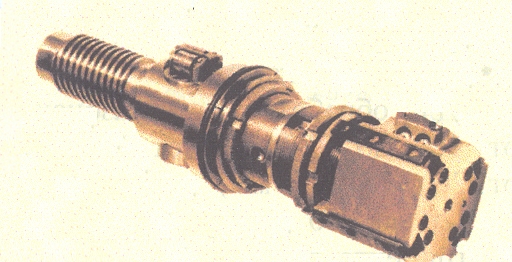

9 - set of stems

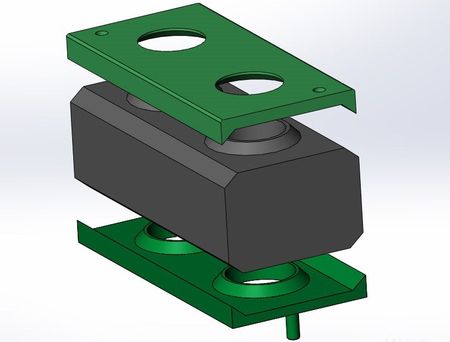

10 - lunette

11 - pressure plates

12 - adjustable pads

13 - replaceable sleeves

Setting up fixtures and machine:

1. Install, center and secure the chuck 1 in the machine plate

2. Install and secure the protective cover 4

3. In accordance with the length and diameter of the hydraulic cylinder being processed, install the steady 10 and the protective cover 5 at the required distance from the chuck.

4. In accordance with the diameter of the hydraulic cylinder being processed, pick up the appropriate stem 9, interchangeable sleeves 1 and install the specified snap-in on racks 2 and 3.

5. To center the axis of the stem 9, racks 2 and 3 with the axis of the spindle of the machine.

6. Fastening the cutting tool, adjusting it to the size, measuring the machined holes are given in the technological process for machining hydraulic cylinders.

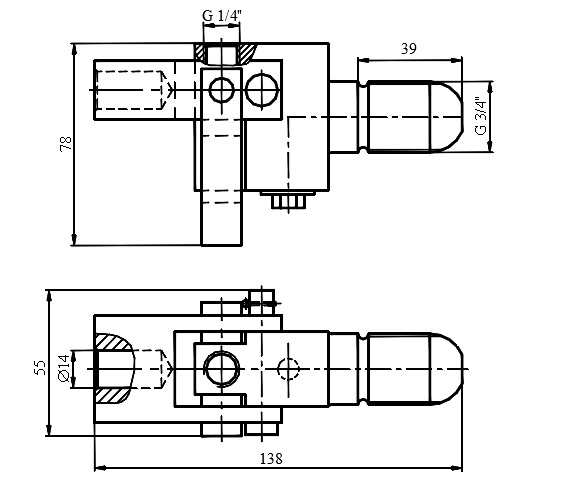

7. The adjustment of the coolant supply pressure to the cutting zone is carried out at the cooling station 6 by means of a bypass valve.

8. Removal of devices and accessories from the machine is performed in the reverse order.

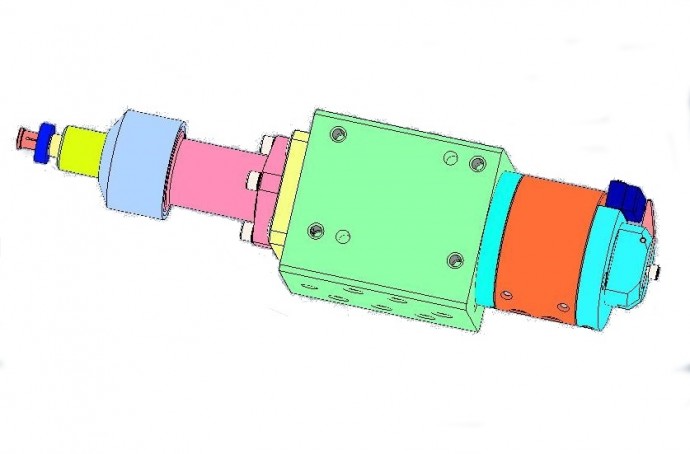

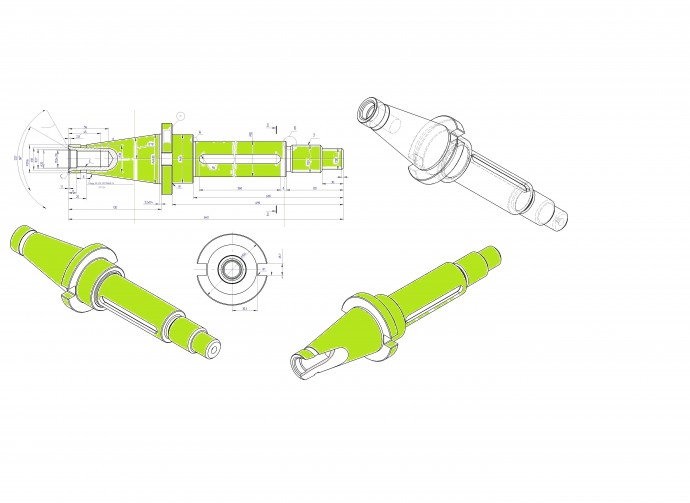

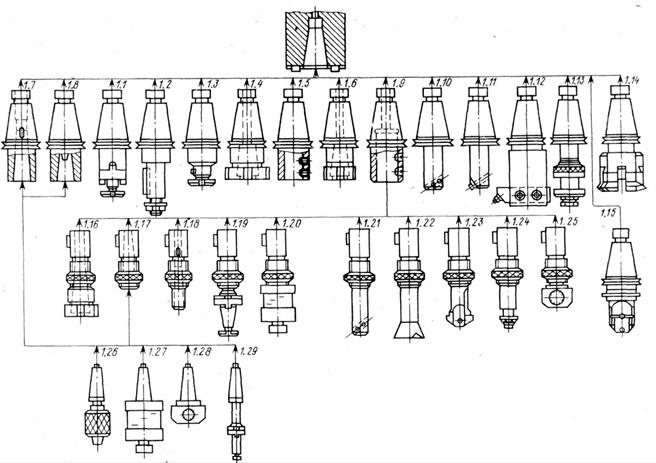

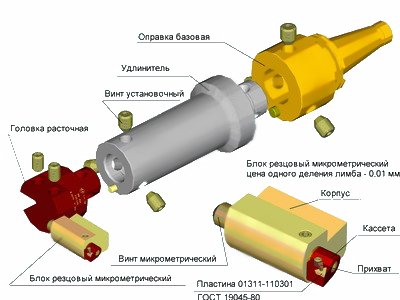

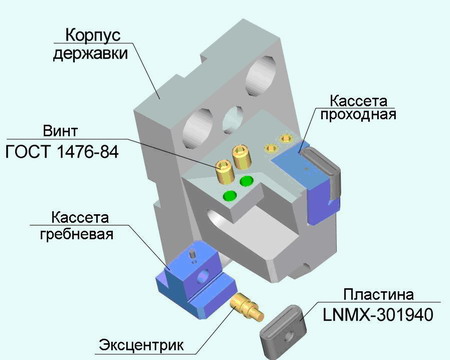

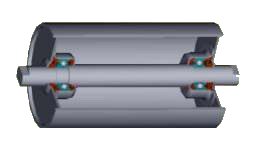

Also, our company produces a special boring and rolling tool for machining internal cylindrical holes:

https://minetek.donetsk.ua/enterprises/84-rastochnoi-i-raskatnoi-instrument.html

en

en ru

ru uk

uk